Preparation method of positive electrode material structure, battery positive electrode, battery and automobile

A positive electrode material, battery positive electrode technology, applied in battery electrodes, positive electrodes, structural parts, etc., can solve the problems of battery charge and discharge rate reduction, unfavorable lithium ion electrolyte transfer, battery charge and discharge rate effects, etc., to improve vibration. Solid density, guaranteed charge-discharge rate performance, guaranteed charge-discharge rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

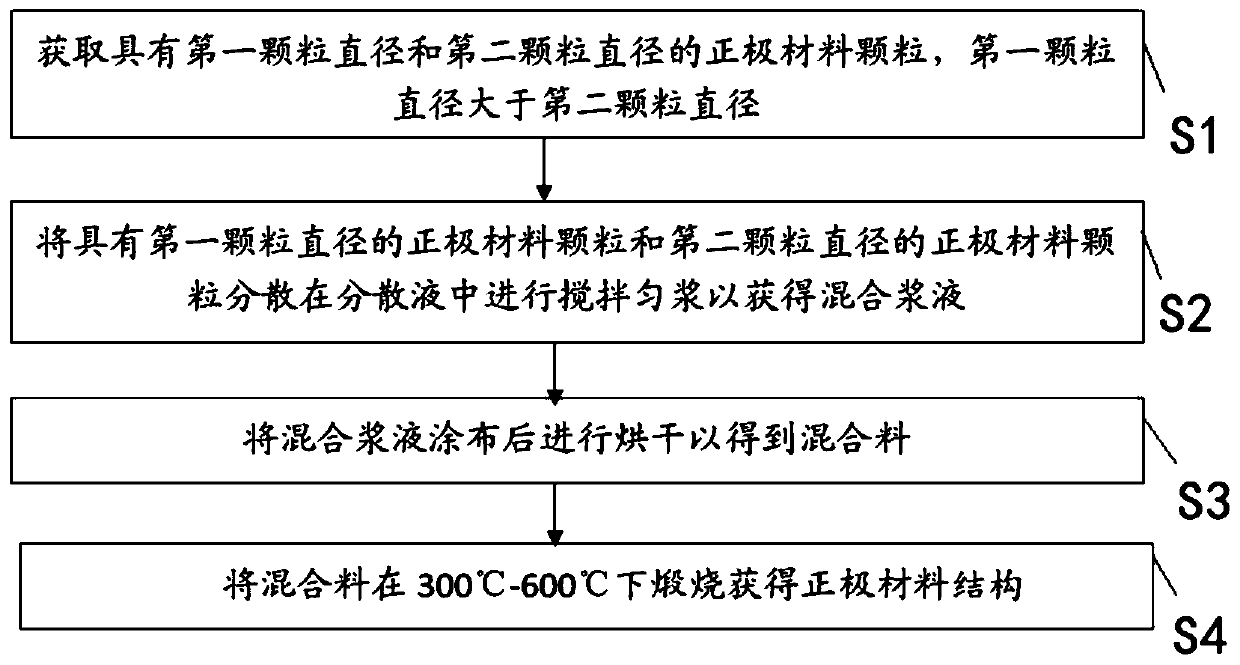

[0034] The preparation method of the positive electrode material structure according to the embodiment of the present invention comprises the following steps:

[0035] Step S1, obtaining positive electrode material particles having a first particle diameter and a second particle diameter, the first particle diameter being greater than the second particle diameter;

[0036] Step S2, dispersing positive electrode material particles with a first particle diameter and positive electrode material particles with a second particle diameter in the dispersion liquid for stirring and homogenizing to obtain a mixed slurry;

[0037] Step S3, drying the mixed slurry after coating to obtain a mixed material;

[0038] Step S4, calcining the mixture at 300°C-600°C to obtain a positive electrode material structure.

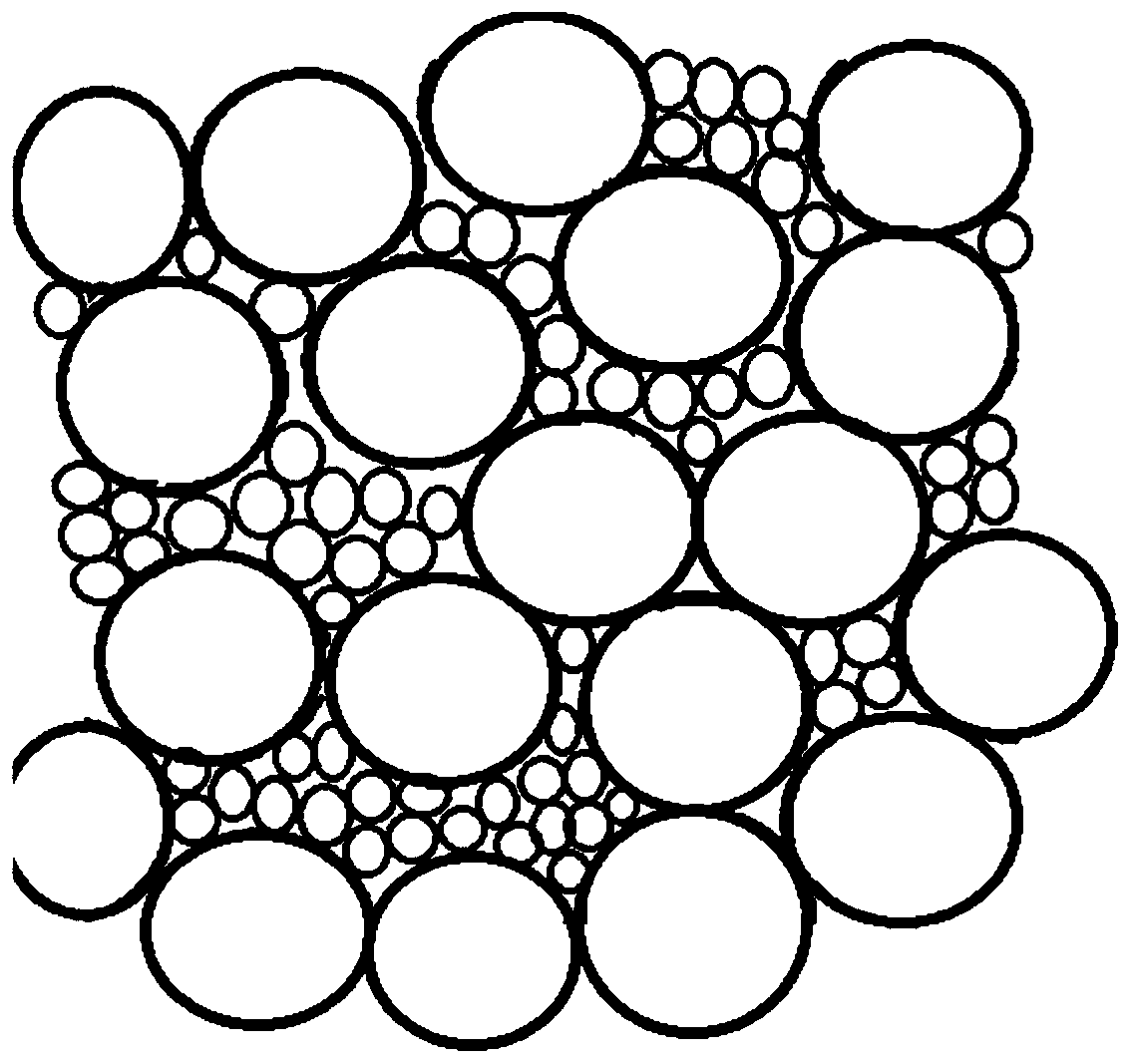

[0039] That is to say, the specific process can be as follows figure 1 As shown, in step S1, positive electrode material particles with a first particle diameter and positive el...

Embodiment 1

[0045] The preparation of lithium iron phosphate particles with a first particle diameter comprises the following steps:

[0046] The iron source material, the phosphorus source material and the lithium source material are respectively added into a solvent to dissolve and mix to obtain a mixed solution, and the solvent is deionized water; wherein, the concentration of iron ions in the mixed solution is 0.5mol / L, and the concentration of phosphate ions is 1mol / L, the concentration of lithium ions is 0.8mol / L; the mixed solution is placed in a closed pressure vessel for reaction, and the mixed solution is reacted under an inert gas protection atmosphere, the reaction temperature is 140°C, and the reaction pressure is 0.61 MPa, the reaction time is 4h; after the reaction is completed, filter and wash to obtain lithium iron phosphate particles with the first particle diameter; the iron source material is ferrous sulfate, the phosphorus source material is phosphoric acid, and the li...

Embodiment 2

[0050] The preparation of lithium iron phosphate particles with a first particle diameter comprises the following steps:

[0051] Add iron source raw materials, phosphorus source raw materials and lithium source raw materials respectively into the solvent to dissolve and mix to obtain a mixed solution, and the solvent is deionized water; wherein, the concentration of iron ions in the mixed solution is 0.7mol / L, and the concentration of phosphate ions is 1.5mol / L, the concentration of lithium ions is 0.5mol / L; the mixed solution is placed in a closed pressure vessel for reaction, and the mixed solution is reacted under an inert gas protection atmosphere, the reaction temperature is 180°C, and the reaction pressure is 0.58MPa, the reaction time is 2h; after the reaction is completed, filter and wash to obtain lithium iron phosphate particles with the first particle diameter; the iron source material is ferrous sulfate, the phosphorus source material is phosphoric acid, and the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com