Application of imvite to magnetron sputtering target material, obtained imvite thin film and application

A technology of magnetron sputtering and montmorillonite, which is applied in sputtering coating, metal material coating process, ion implantation plating, etc., can solve the problems that limit the application field of montmorillonite, and achieve good flatness and porosity The effect of low rate and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The application of montmorillonite in magnetron sputtering target material, described montmorillonite target material is prepared by following method:

[0043] (1) Take the montmorillonite powder and add it to absolute alcohol, the weight ratio of the montmorillonite powder and absolute alcohol is 1:1 to obtain a suspension;

[0044] (2) coating the suspension obtained in step (1) on the inner wall of the mould, around the upper press head and the contact surface, around the lower press head and the contact surface, the inner and outer surfaces of the bushing, and all surfaces of the upper and lower gaskets;

[0045] (3) Assemble the mold sleeve and bushing together, put the lower pressure head into the mold cavity, put the lower protective gasket, then take the montmorillonite powder, put it into the mold cavity, scrape the surface, and put it into the upper protective gasket piece, and then insert the upper indenter;

[0046] (4) Put the mold installed in step (3) in...

Embodiment 2

[0048] The application of montmorillonite in magnetron sputtering target material, described montmorillonite target material is prepared by following method:

[0049] (1) Take the montmorillonite powder and add it to absolute alcohol, the weight ratio of the montmorillonite powder and absolute alcohol is 1:2 to obtain a suspension;

[0050] (2) coating the suspension obtained in step (1) on the inner wall of the mould, around the upper press head and the contact surface, around the lower press head and the contact surface, the inner and outer surfaces of the bushing, and all surfaces of the upper and lower gaskets;

[0051] (3) Assemble the mold sleeve and bushing together, put the lower pressure head into the mold cavity, put the lower protective gasket, then take the montmorillonite powder, put it into the mold cavity, scrape the surface, and put it into the upper protective gasket piece, and then insert the upper indenter;

[0052] (4) Put the mold installed in step (3) in...

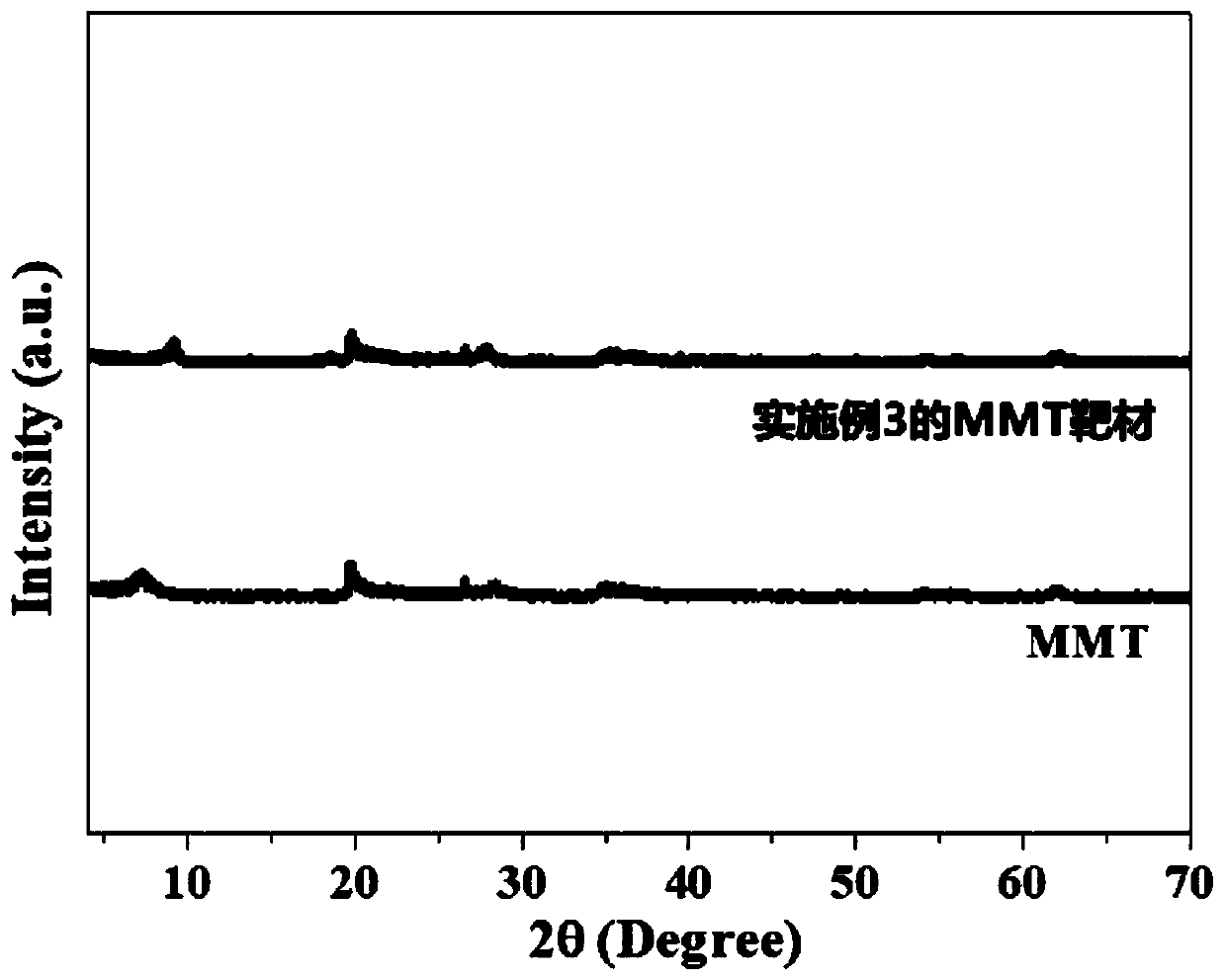

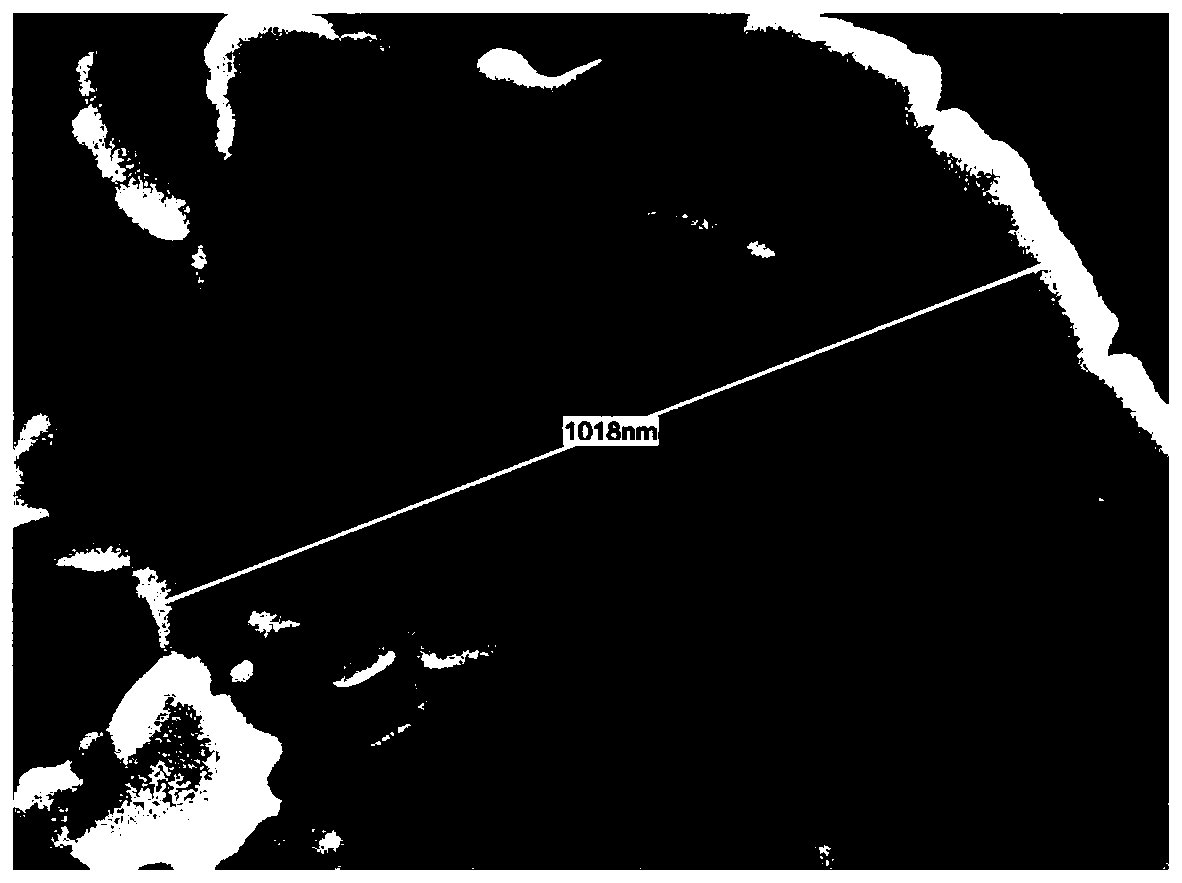

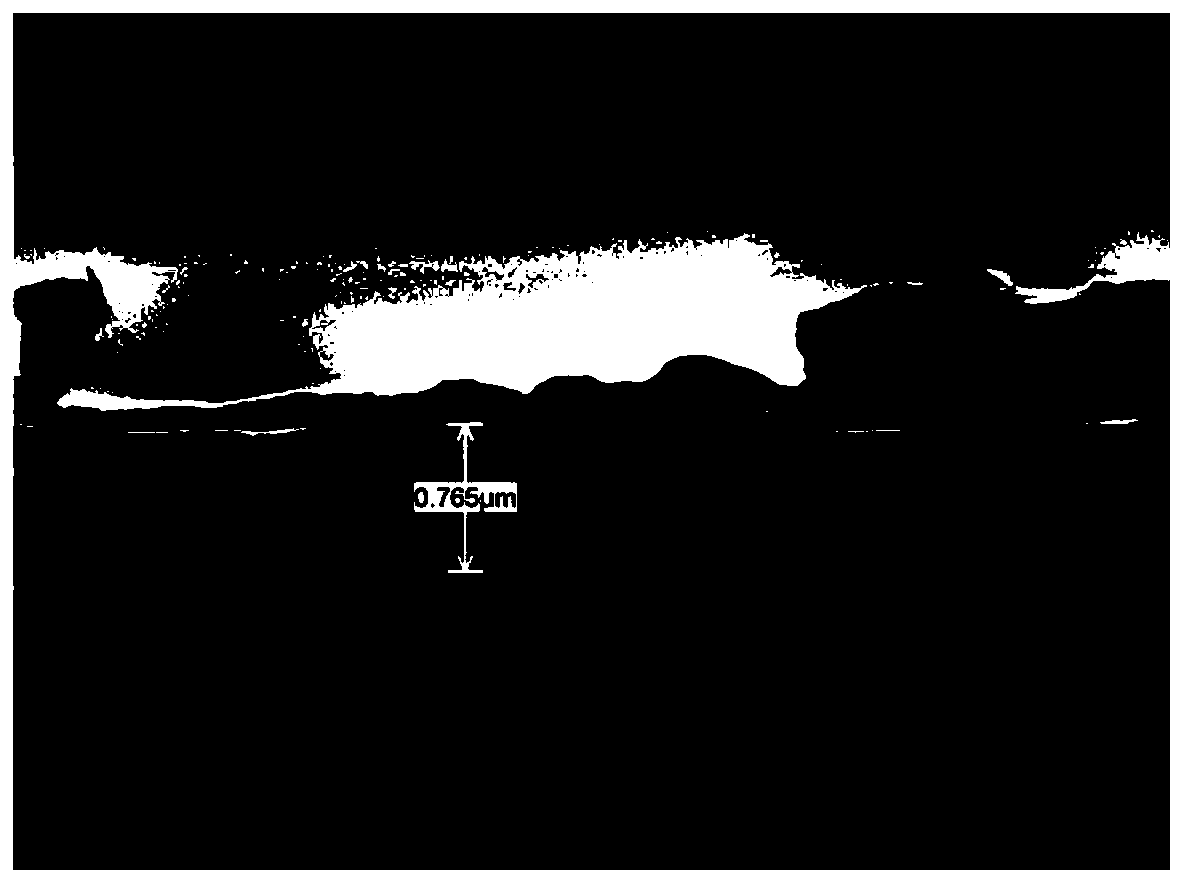

Embodiment 3

[0054] The application of montmorillonite in magnetron sputtering target material, described montmorillonite target material is prepared by following method:

[0055] (1) Take the montmorillonite powder and add it to absolute alcohol, the weight ratio of the montmorillonite powder and absolute alcohol is 1:1 to obtain a suspension;

[0056] (2) coating the suspension obtained in step (1) on the inner wall of the mould, around the upper press head and the contact surface, around the lower press head and the contact surface, the inner and outer surfaces of the bushing, and all surfaces of the upper and lower gaskets;

[0057] (3) Assemble the mold sleeve and bushing together, put the lower pressure head into the mold cavity, put the lower protective gasket, then take the montmorillonite powder, put it into the mold cavity, scrape the surface, and put it into the upper protective gasket piece, and then insert the upper indenter;

[0058] (4) Put the mold installed in step (3) in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com