Waterborne intumescent flame-retardant coating and preparation method thereof

An intumescent technology for fire-resistant coatings, applied in fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve the problems of difficult protection of substrates, waste of metal resources and energy, and unsatisfactory protective performance of fire-resistant coatings, and achieve chemical resistance , Oxygen isolation, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

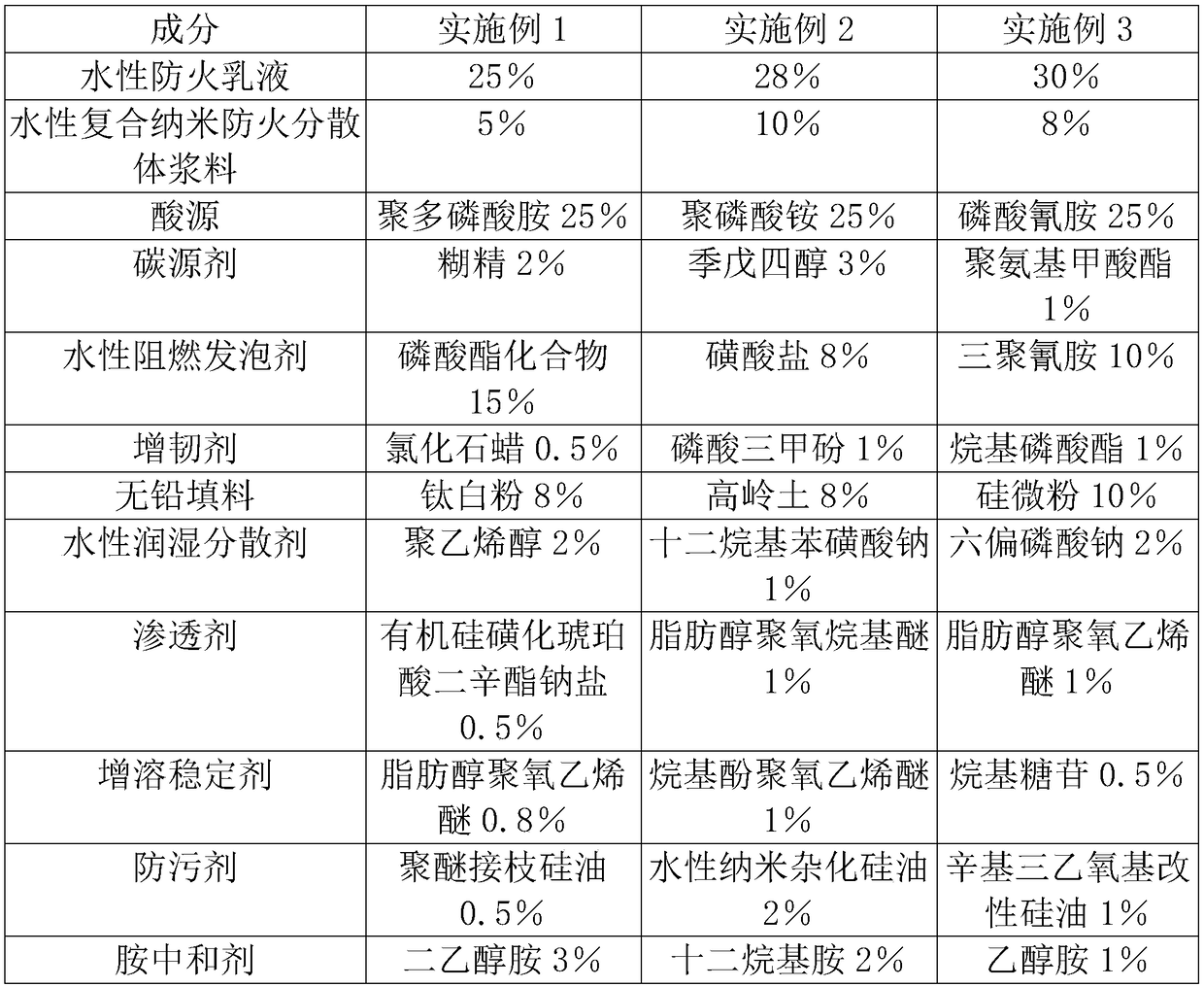

[0029] The present invention also provides several specific implementation formulas as follows, and the percentages in the table are all mass percentages:

[0030]

[0031]

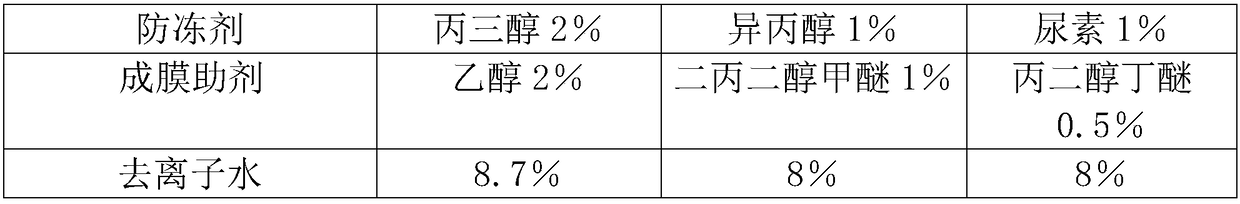

[0032] The specific embodiment of water-based fireproof emulsion in embodiment 1-3 is as follows:

[0033]

[0034] Although the above formulations are slightly different in composition, the technical effect achieved by the obtained water-based intumescent fireproof coating is generally consistent.

[0035] The water-based fireproof emulsion of the above-mentioned embodiments 1-3 China is obtained through the following method steps: the described water-based fireproof emulsion is obtained through the following method steps: Weigh the acrylic mixed monomer and emulsifier according to the formula amount, and mix them at 2000~3000rpm Stir and disperse for 20 to 35 minutes at a rotating speed of 20 to 35 minutes, and carry out pre-emulsification in the pretreatment tank to prepare a pre-emulsified mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com