Split column, split combined overvoltage protector

A combined, overvoltage technology, applied in the direction of overvoltage protection resistors, resistors, electrical components, etc., can solve the problems of overall damage, too many high-energy resistors, insufficient installation space, etc., to prolong life and reduce accidents. Incidence, effect of strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

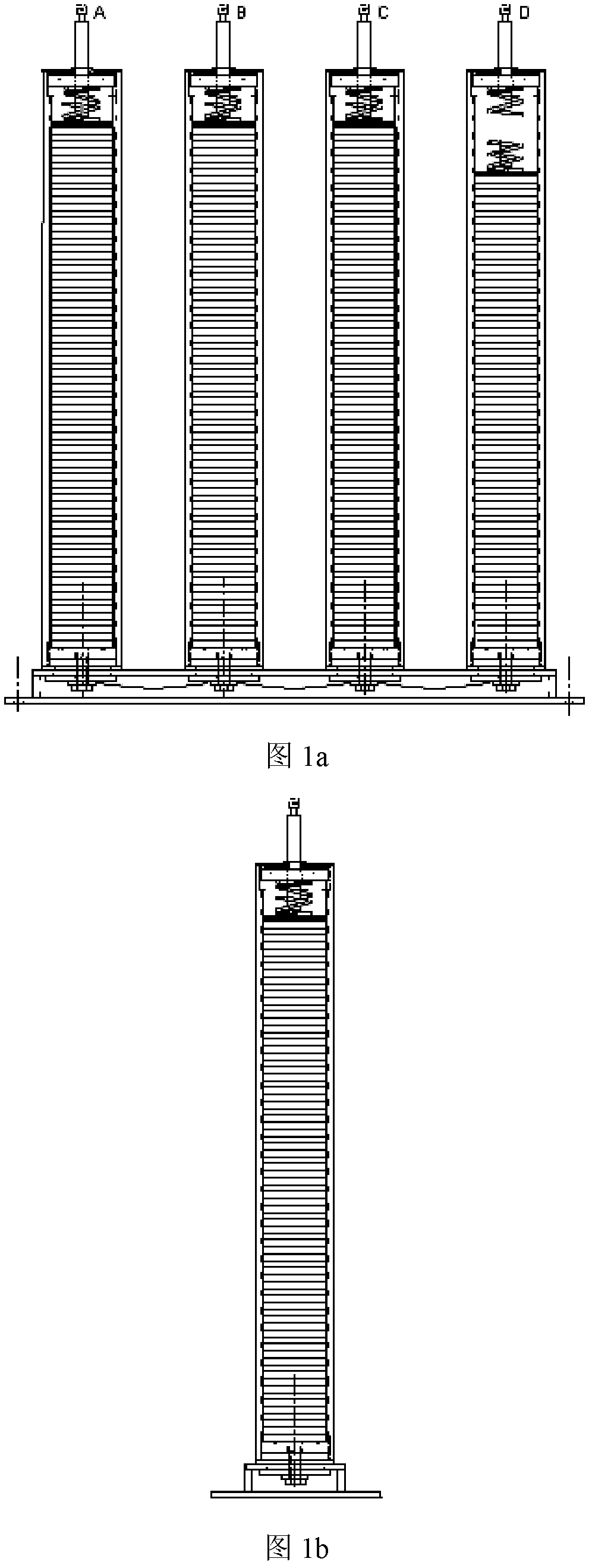

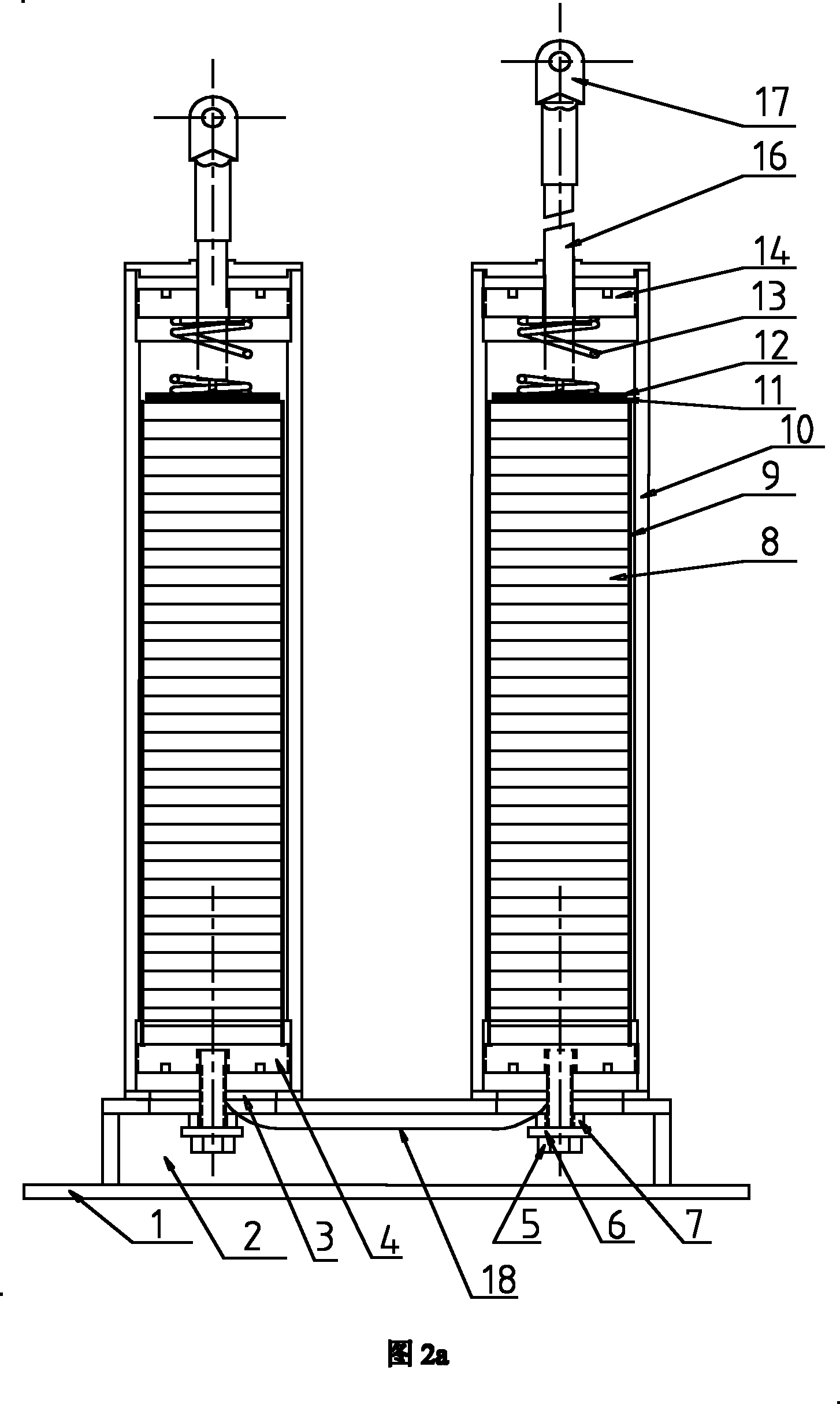

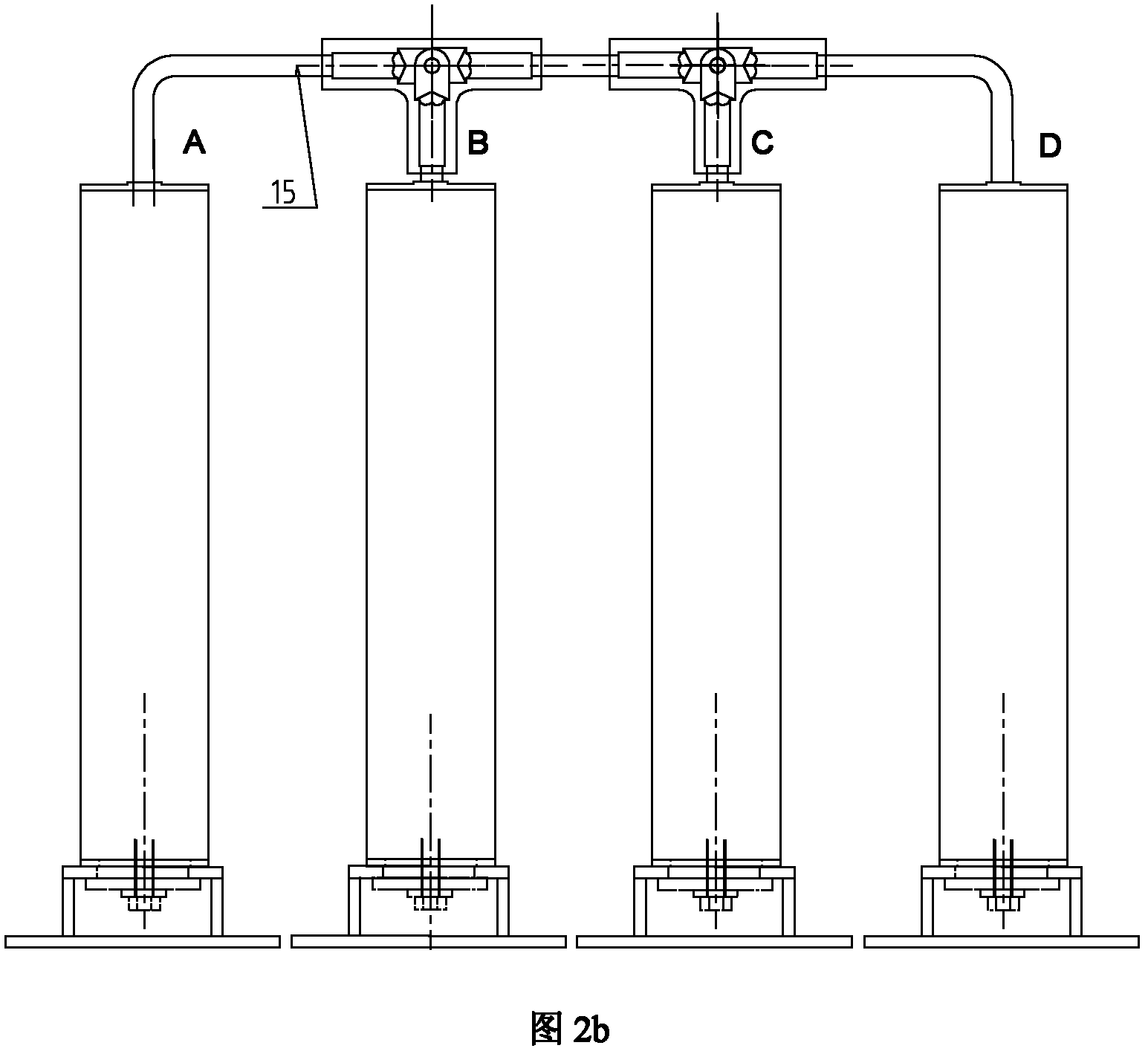

[0033] Such as figure 2 shown. Detachable column, split combined overvoltage protector, including A, B, C, D four-phase column, a plurality of resistors 8 are stacked in the column, and the bottom of each phase column is respectively provided with a column for installation Bottom box 2, bottom box 2 with bottom box cover plate 1, and each column is a parallel double column, and the lowest layer of resistors in the double column passes through the wires 18 buried in the corresponding bottom box Electrically connected, the uppermost resistance sheets in the double cylinders are respectively electrically connected to the cables 16 drawn from the top of the double cylinders, and the cable lead-out end of one of the cylinders in each phase is electrically connected to the protected equipment of the power system, The cable lead-out end of the other column is used as the midpoint, and the midpoints of different phase columns are electrically connected through the wire 15 in turn. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com