Method for utilizing sulfur-containing refining waste residue for refining slag

A technology for refining waste slag and refining slag, applied in the direction of improving process efficiency, calcium/strontium/barium oxide/hydroxide, etc., can solve problems such as increased energy consumption, environmental pollution, loss of desulfurization effect, etc., to ensure cleanliness , The economic benefits are huge, and the effect of reducing the energy consumption of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

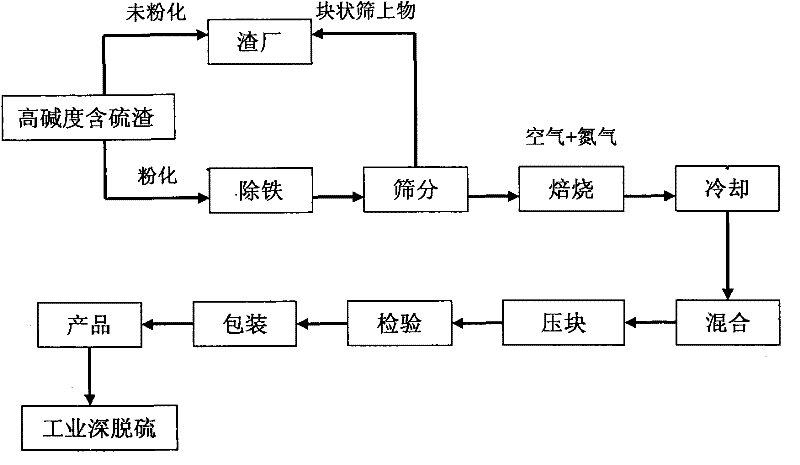

[0023] Embodiment 1: According to the technological process of accompanying drawing, the refining slag recovered is stored for 5 days, and after it is naturally pulverized, it is screened with a 100-mesh sieve, and treated by magnetic separation to remove metal iron particles and unpowdered slag block impurities, Put the sieves of each furnace into the mixer and mechanically stir them evenly to obtain the sulfur-containing refining waste. The composition is shown in Table 1-1. Send it into the rotary kiln, control the temperature at 1150°C, the hot air is a mixture of air and nitrogen, the ratio is 70:30V / V%, the partial pressure of oxygen is 0.147atm, roast for 40 minutes, cool naturally, chemical detection, the obtained roasting The composition of the powder is shown in Table 1-2. The roasted powder is sent into a dry-type briquetting machine, and pressed into a flat ball of 2.0cm×4.0cm to obtain the product of the present invention.

[0024] Add the pellets to 100 kg of pre...

Embodiment 2

[0029] Embodiment 2: According to the technological process of accompanying drawing, the refining slag recovered is stored for 10 days, after it is naturally pulverized, it is sieved with a 100-mesh sieve, and magnetically separated to remove metal iron particles and unpowdered slag block impurities, Put the undersieve into the mixer, and mechanically stir it evenly to obtain sulfur-containing refining waste residue, whose composition is shown in Table 2-1, and send it into the rotary kiln, the temperature is controlled at 1120°C, the hot air is a mixture of air and nitrogen, and the ratio is It is 65:35V / V%, the oxygen partial pressure is 0.137atm, roasted for 50 minutes, cooled naturally, and chemically detected. The composition of the roasted powder obtained is shown in Table 2-2. Send the calcined powder into a dry-type ball briquetting machine, and press it into a flat ball of 3.0 cm×6.0 cm to obtain the product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com