Method for producing high-strength copper alloy large-sized cast ingot by vacuum melting

A vacuum smelting and copper alloy technology, applied in the field of vacuum smelting to produce high-strength copper alloy large-scale ingots, can solve the problems of Sn segregation ingots, shrinkage porosity or shrinkage cavities, etc., to reduce inclusions, improve strength, and increase dispersion strengthening effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

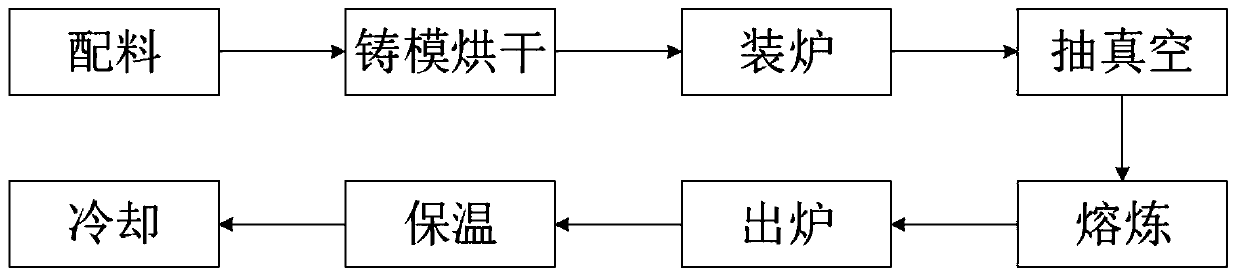

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0032] (1) Ingredients: the raw materials used and their proportioning ratio are shown in Table 1,

[0033] Table 1

[0034] Element Grade standard mass percentage Electrolytic copper Cu99.95 GB / T467-2010 76.30% Electrolytic nickel Ni99.95 GB / T6515-2010 14.00% Tin ingots Sn99.95 GB / T 728-2010 9.00% Niobium bar Nb1 GB / T 14842-2010 0.10% Electrolytic manganese JMn98 GB / T 2774-2010 0.60%

[0035] (2) Mold drying: put the cast iron mold into a drying furnace and heat it to 900°C, and dry it for 1 hour;

[0036] (3) Furnace loading: First load tin ingots, cut and pave the entire bottom of the crucible, add electrolytic nickel above the tin ingots, add niobium in the middle of the crucible, and finally add electrolytic copper, electrolytic manganese is added fro...

Embodiment 2

[0045] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0046] (1) Ingredients: the raw materials used and their proportioning ratio are shown in Table 2,

[0047] Table 2

[0048] Element Grade standard mass percentage Electrolytic copper Cu99.95 GB / T467-2010 76.60% Electrolytic nickel Ni99.95 GB / T6515-2010 15.00% Tin ingots Sn99.95 GB / T 728-2010 8.00% Niobium bar Nb1 GB / T14842-2007 0.20% Electrolytic manganese JMn98 GB / T 2774-2008 0.20%

[0049] (2) Mold drying: put the cast iron mold into a drying furnace and heat it to 800°C, and dry it for 2 hours;

[0050](3) Furnace loading: First load tin ingots, cut and pave the entire bottom of the crucible, add electrolytic nickel above the tin ingots, add niobium in the middle of the crucible, and finally add electrolytic copper, electrolytic manganese is added from...

Embodiment 3

[0060] In this embodiment, a method for producing high-strength copper alloy large-scale ingots by vacuum smelting is obtained by the following method:

[0061] (1) Ingredients: the raw materials used and their proportioning ratio are shown in Table 3,

[0062] table 3

[0063] Element Grade standard mass percentage Electrolytic copper Cu99.95 GB / T467-2010 76.45% Electrolytic nickel Ni99.96 GB / T6515-2010 16% Tin ingots Sn99.97 GB / T 728-2010 7% Niobium bar Nb1 GB / T14842-2007 0.15% Electrolytic manganese JMn98 GB / T 2774-2008 0.40%

[0064] (2) Mold drying: put the cast iron mold into a drying furnace and heat it to 700°C, and dry it for 4 hours;

[0065] (3) Furnace loading: First load tin ingots, cut and pave the entire bottom of the crucible, add electrolytic nickel above the tin ingots, add niobium in the middle of the crucible, and finally add electrolytic copper, electrolytic manganese is added from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com