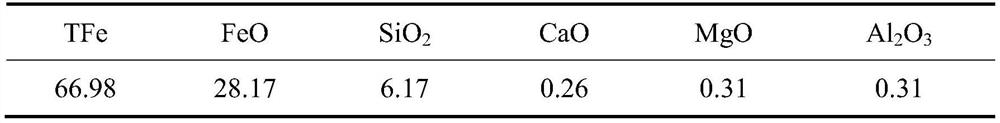

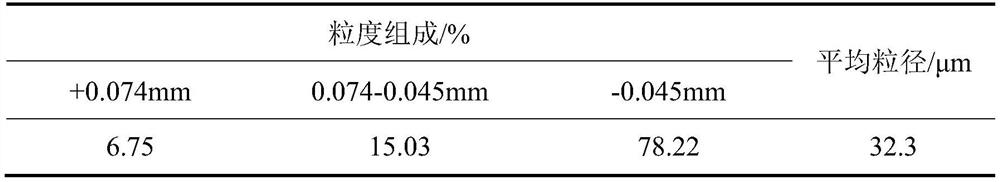

An Oxidation Method for Optimizing Thermal Parameters of Fine Magnetite Concentrate Pellets

A technology of magnetite concentrate and thermal parameters, applied in furnaces, furnace types, rotary drum furnaces, etc., can solve the problems of excessively fine particle size of magnetite concentrate, low pellet strength, hindered oxidation, etc., to improve strength and quality, A wide range of adaptations, avoiding the effect of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

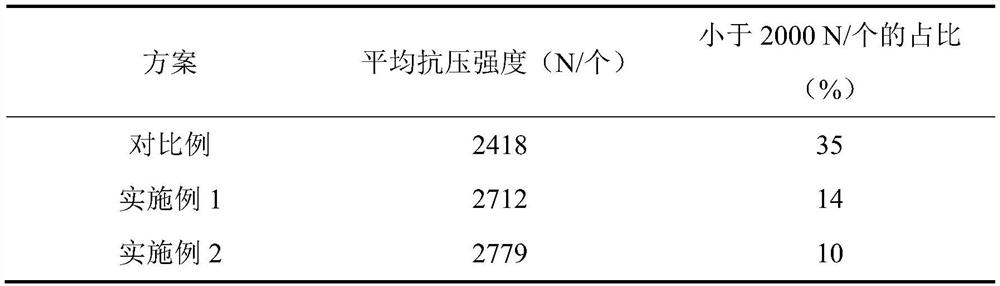

Embodiment 1

[0041] The optimized thermal parameters are as follows: the air temperature in the preheating stage I is increased to 600°C, and the heating rate is increased to 100°C / min; the temperature in the preheating stage II is reduced to 920°C; The operation method is to increase the material layer height by 20%, and reduce the machine speed by 20%; the maximum roasting temperature of the rotary kiln is reduced to 1250°C, and the oxygen content of the roasting atmosphere is increased from 17% to 17.5%; the first section of the annular cooler reduces the air volume by 5%, and the environmental The outlet air temperature of the second section of the chiller is increased by 100°C; at this time, the oxidation ratio of the fine-grained magnetite concentrate pellets in the preheating section, roasting section, and cooling section is 50:30:20, which eliminates the shell structure of the pellets. The average strength of pellets increased to 2712N / piece, and the proportion of pellets below 2000...

Embodiment 2

[0043]The optimized thermal parameters are as follows: the air temperature in the preheating stage I is increased to 750°C, and the heating rate is increased to 150°C / min; the temperature in the preheating stage II is reduced to 880°C; The operation method is to increase the height of the material layer by 30%, and reduce the machine speed by 30%; the maximum roasting temperature of the rotary kiln is reduced to 1200°C, and the oxygen content of the roasting atmosphere is increased from 18% to 18.5%; the first section of the ring cooler reduces the air volume by 10%, and the ring The outlet air temperature of the second section of the chiller is increased by 150°C; at this time, the oxidation ratio of the fine-grained magnetite concentrate pellets in the preheating section, roasting section, and cooling section is 65:20:15, eliminating the shell structure of the pellets, The average strength of pellets increased to 2779N / piece, and the proportion of pellets below 2000N / piece de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com