Unshaped refractory for heat treatment furnace and lining structure of the furnace

A heat treatment furnace and refractory technology, applied in the direction of lining repair, etc., can solve the problems of intrusion, cracking or peeling of furnace materials, melting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

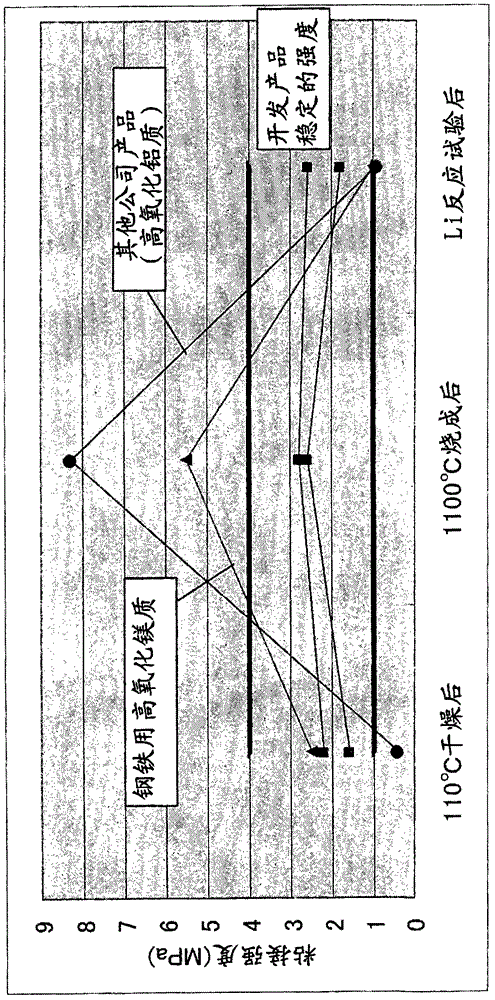

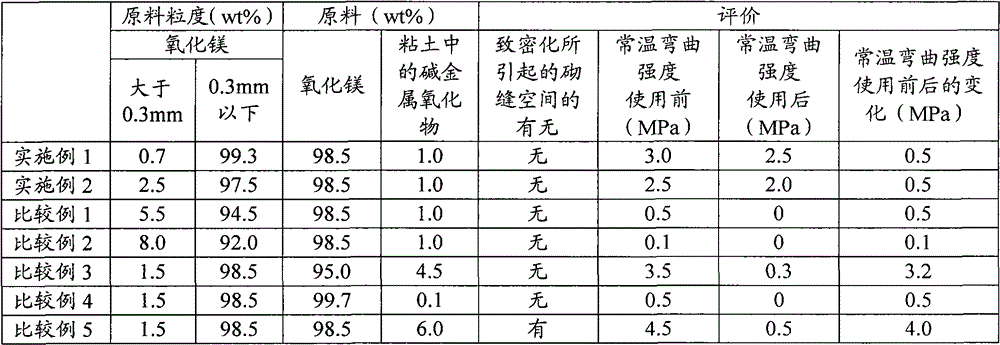

[0054] Tables 1 to 4 show the monolithic refractories made of the raw materials of Examples 1 to 6 and Comparative Examples 1 to 8, whether or not the densification of the joints occurs during the sintering process is regarded as the "joint space". The result of evaluating the presence or absence of ", and the result of strength measurement by the same method as the above-mentioned strength measurement method. In Tables 1 to 4, "bending strength at room temperature before use" refers to the strength after drying (110°C×24hrs), and "bending strength at room temperature after use" refers to the strength after the reaction test.

[0055] Table 1

[0056]

[0057] The basic monolithic refractory for the lithium composite oxide heat treatment furnace of the present invention is the monolithic refractory containing refractory clay and a refractory aggregate, and the refractory aggregate contains 96 to 99.5% by mass of a magnesia raw material , the refractory clay contains clay w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com