A healthy and environment-friendly biomass mattress provided with a loofah sponge functional layer

The technology of a loofah sponge and a functional layer is applied in the field of healthy and environmentally friendly biomass mattresses provided with a loofah sponge functional layer, which can solve problems such as unfavorable human health and achieve the effect of being easy to bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

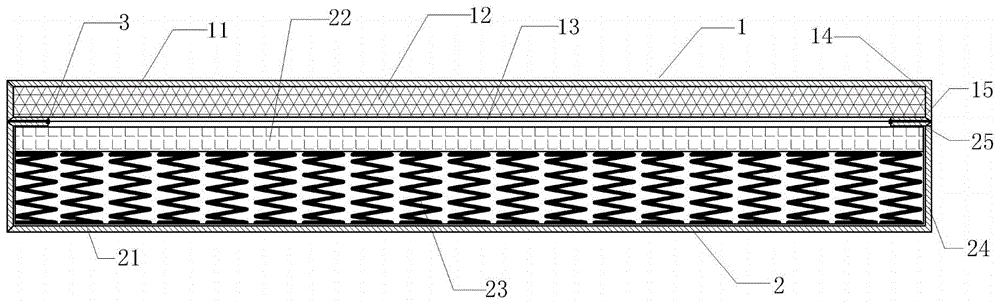

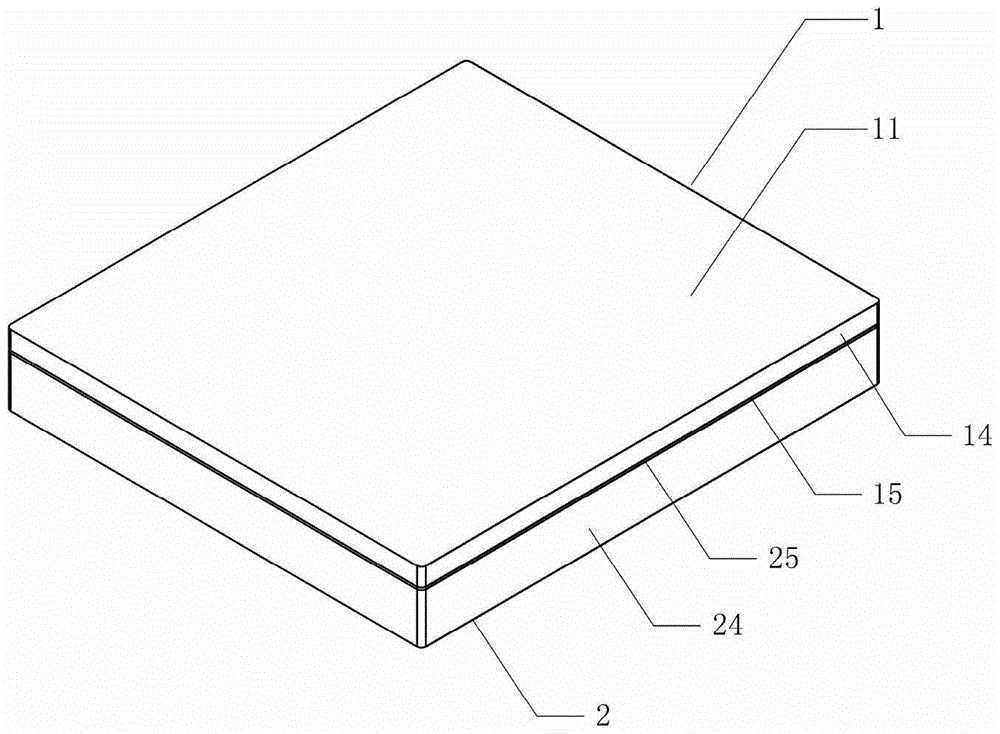

[0056] As shown in the figure, a healthy and environmentally friendly biomass mattress provided with a loofah sponge functional layer, the mattress includes a mattress upper layer 1 and a mattress lower layer 2;

[0057] The upper layer 1 of the mattress is a comfort layer 12 filled with elastomer, and the comfort layer is covered by an upper fabric composite layer 11, a bottom liner 13 and an upper edge 14;

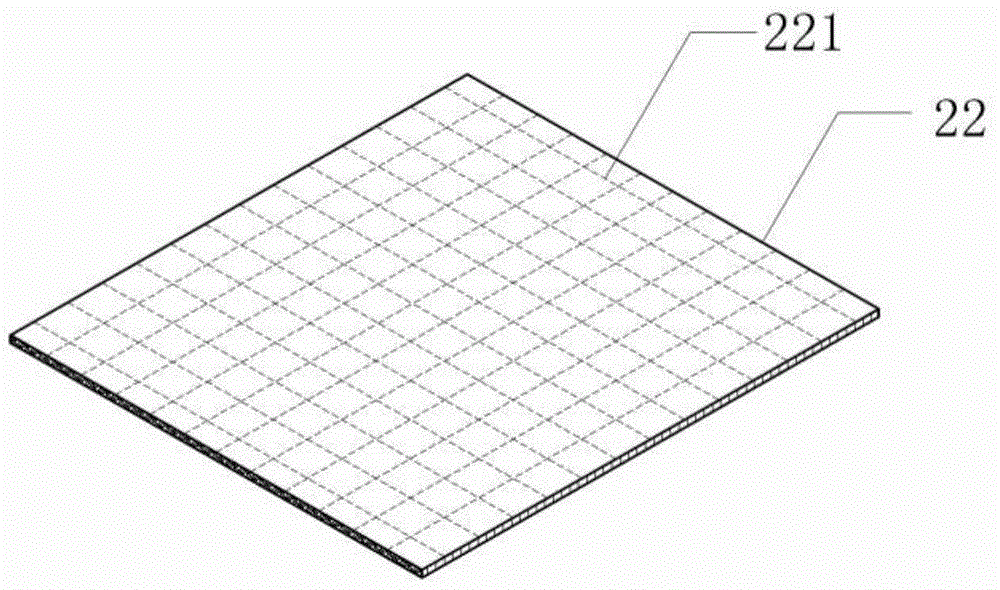

[0058] The lower layer 2 of the mattress is composed of a loofah sponge functional layer 22 and a spring core layer 23. The spring body 231 of the spring core layer is an independent pocket spring or fine steel interlocking spring or brushed spring; the spring core layer is covered with an independent bag The upper and lower sides of the bed net 23 of spring or stainless steel chain spring or brushed spring are provided with 400g / m 2 -800g / m 2 A base layer 232 made of cotton felt or other felts with certain elasticity; if the spring core layer is a stainless steel chain...

Embodiment 2

[0065] As preferably, described loofah sponge sheet is processed and obtained as follows:

[0066] ①First choose a density of 19Kg / m 3 -30Kg / m 3 The loofah is the primary raw material;

[0067] ②Wash the selected loofah raw material, dry it in the sun, and control the water content within 7%; then cut off the two ends to obtain the loofah column before flattening, such as Figure 4 , 5 Shown; Then it is cut along the loofah shaft side, after removing the core material 52; Flatten the sapwood 51; The loofah columnar body 5 in the flattening process, as Figure 6 , 7 shown;

[0068] ③ Screen the sapwood again, and select the gram weight ≥ 160g / m 2 The flattened sapwood of loofah is the final raw material of loofah sponge sheet;

[0069] ④ Lay the selected flattened loofah sapwood in the same direction, with the smooth surface of the outer layer of the loofah facing up and the surface of the inner layer facing down. The upper and lower layers are staggered and stacked. Th...

Embodiment 3

[0076] As preferably, described loofah sponge sheet can also be processed and obtained according to the following steps:

[0077] ①First choose a density of 19Kg / m 3 -30Kg / m 3 The loofah is the primary raw material;

[0078] ②Wash the selected loofah raw material, dry it in the sun, and control the water content within 7%; then cut off the two ends to obtain the loofah column before flattening, such as Figure 4 , 5 Shown; Then it is cut along the loofah shaft side, after removing the core material 52; Flatten the sapwood 51; The loofah columnar body 5 in the flattening process, as Figure 6 ,7 shown;

[0079] ③ Screen the sapwood again, and select the gram weight ≥ 160g / m 2 The flattened sapwood of loofah is the final raw material of loofah sponge sheet;

[0080] ④Pave the selected flattened loofah sapwood in the same direction, with the smooth surface of the outer layer of the loofah facing up and the inner surface facing down; laying multiple layers, the density and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com