Aluminum foil reinforced TPO butyl rubber self-adhesive waterproof coiled material with backing and preparation method thereof

A self-adhesive waterproof membrane, butyl glue technology, applied in the direction of adhesive, film/sheet adhesive, etc., can solve the problem of poor adhesion between the substrate and the base layer, no adhesion, etc., to improve reliability The effect of improving the performance, convenience of construction, and construction limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

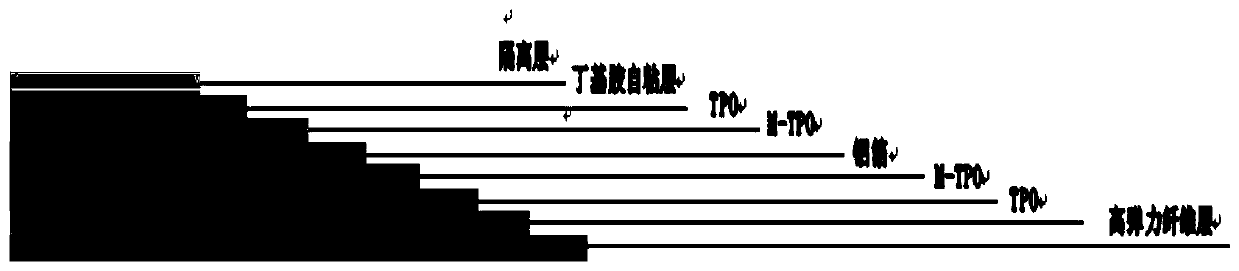

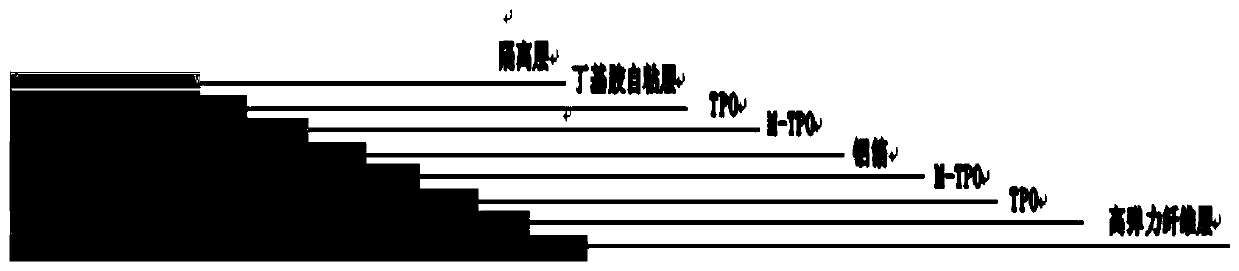

Image

Examples

Embodiment 1

[0029] Step 1): Add polypropylene resin, propylene-based elastomer and TPO masterbatch according to 25%: 50%: 25% and add to cylinder A; take M-TPO resin and add to cylinder B; start extrusion, at temperature Extrude a sheet of specified thickness in mold A at 190°C-210°C, wherein TPO is on the back and M-TPO is on the front to obtain a TPO-M-TPO composite sheet; the temperature of the extruder A screw is : The feeding section is 170°C-180°C, the plasticizing section is 180°C-190°C, the metering section is 190°C-200°C; the temperature of the extruder B screw is: the feeding section is 170°C-180°C, and the plasticizing section is 190°C -200°C, metering section 200°C-210°C;

[0030] The TPO masterbatch is prepared by the following steps: 65 parts of magnesium hydroxide, 10 parts of PP resin K8003, 15 parts of POE 6102, 2 parts of light stabilizer 2020, 0.5 parts of antioxidant B60 and 6 parts of stearic acid 1801 After mixing evenly at high speed, add it to the parallel twin-sc...

Embodiment 2

[0037] Step 1): Add polypropylene resin, propylene-based elastomer and TPO masterbatch according to 35%: 35%: 30% and add to cylinder A; take M-TPO resin and add to cylinder B; start extrusion, at temperature Extrude a sheet of specified thickness in mold A at 190°C-210°C, wherein TPO is on the back and M-TPO is on the front to obtain a TPO-M-TPO composite sheet; the temperature of the extruder A screw is : The feeding section is 170°C-180°C, the plasticizing section is 180°C-190°C, the metering section is 190°C-200°C; the temperature of the extruder B screw is: the feeding section is 170°C-180°C, and the plasticizing section is 190°C -200°C, metering section 200°C-210°C;

[0038] The TPO masterbatch is prepared through the following steps: Take 75 parts of magnesium hydroxide, 5 parts of PP resin K8003, 30 parts of POE6102, 0.5 parts of light stabilizer 2020, 2 parts of antioxidant B60 and 2 parts of stearic acid 1801 high speed After mixing evenly, add it to the parallel tw...

Embodiment 3

[0045] Step 1): Add polypropylene resin, propylene-based elastomer and TPO masterbatch according to 30%: 45%: 25% and add to cylinder A; take M-TPO resin and add to cylinder B; start extrusion, at temperature Extrude a sheet of specified thickness in mold A at 190°C-210°C, wherein TPO is on the back and M-TPO is on the front to obtain a TPO-M-TPO composite sheet; the temperature of the extruder A screw is : The feeding section is 170°C-180°C, the plasticizing section is 180°C-190°C, the metering section is 190°C-200°C; the temperature of the extruder B screw is: the feeding section is 170°C-180°C, and the plasticizing section is 190°C -200°C, metering section 200°C-210°C;

[0046] The TPO masterbatch is prepared by the following steps: take 70 parts of magnesium hydroxide, 5 parts of PP resin K8003, 20 parts of POE6102, 1 part of light stabilizer 2020, 1 part of antioxidant B60 and 3 parts of stearic acid 1801 high speed After mixing evenly, add it to the parallel twin-screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com