Triphenylamine benzothiadiazole polymer containing biphenyl structure as well as preparation method and application thereof

A technology of benzothiadiazole and biphenyl structure, which is applied in the field of triphenylamine benzothiadiazole polymers, can solve the problems of poor heat resistance and low solubility, and achieve increased solubility, good solubility, and discoloration obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

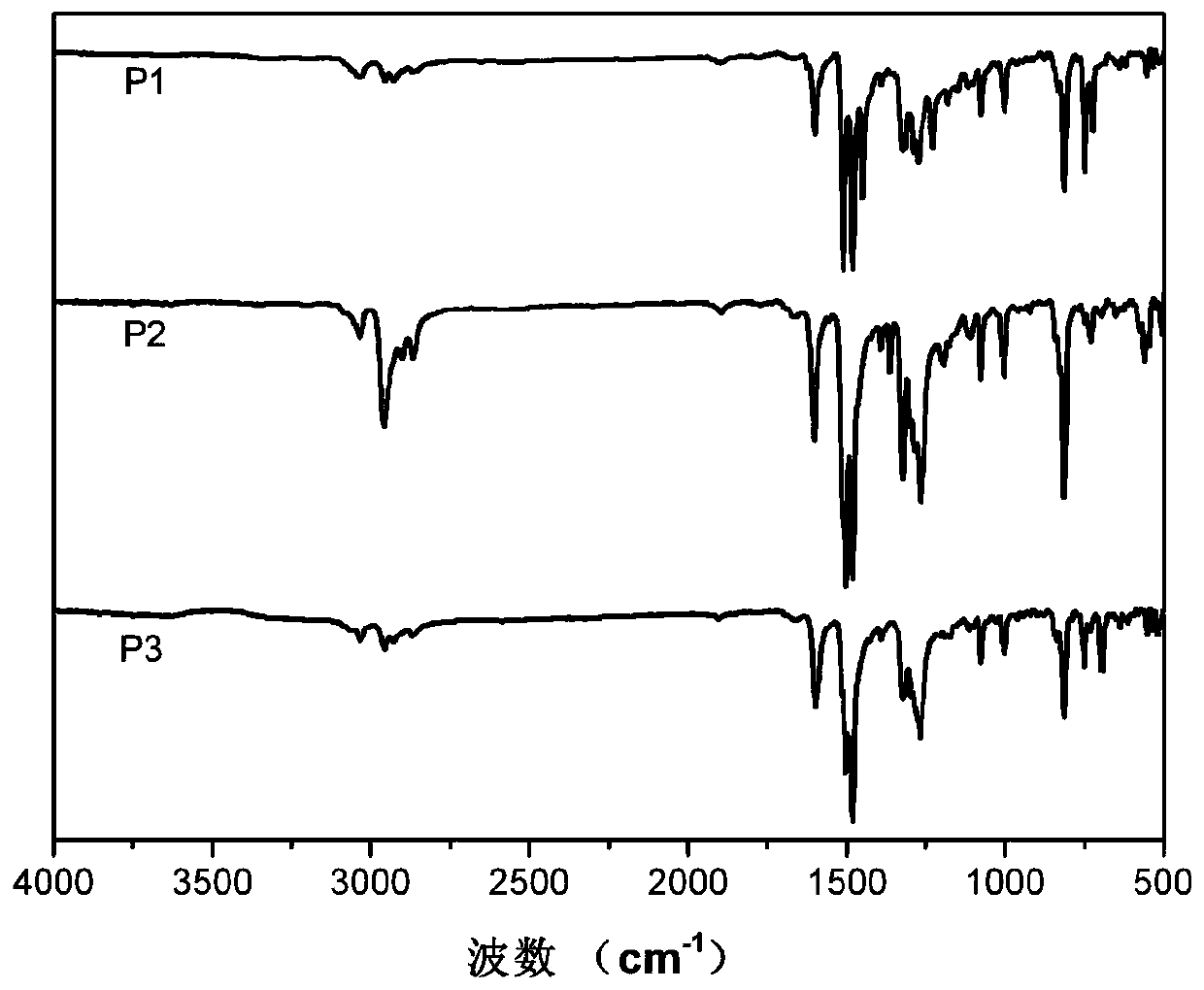

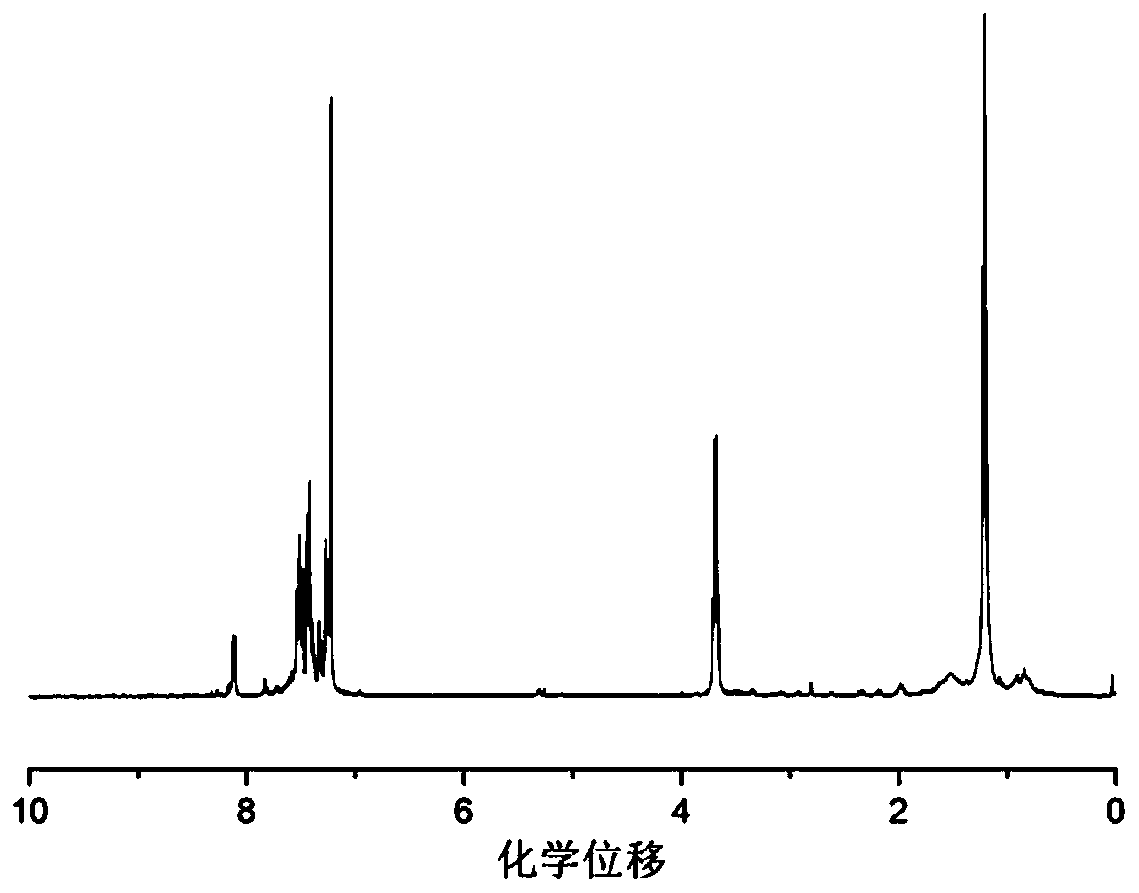

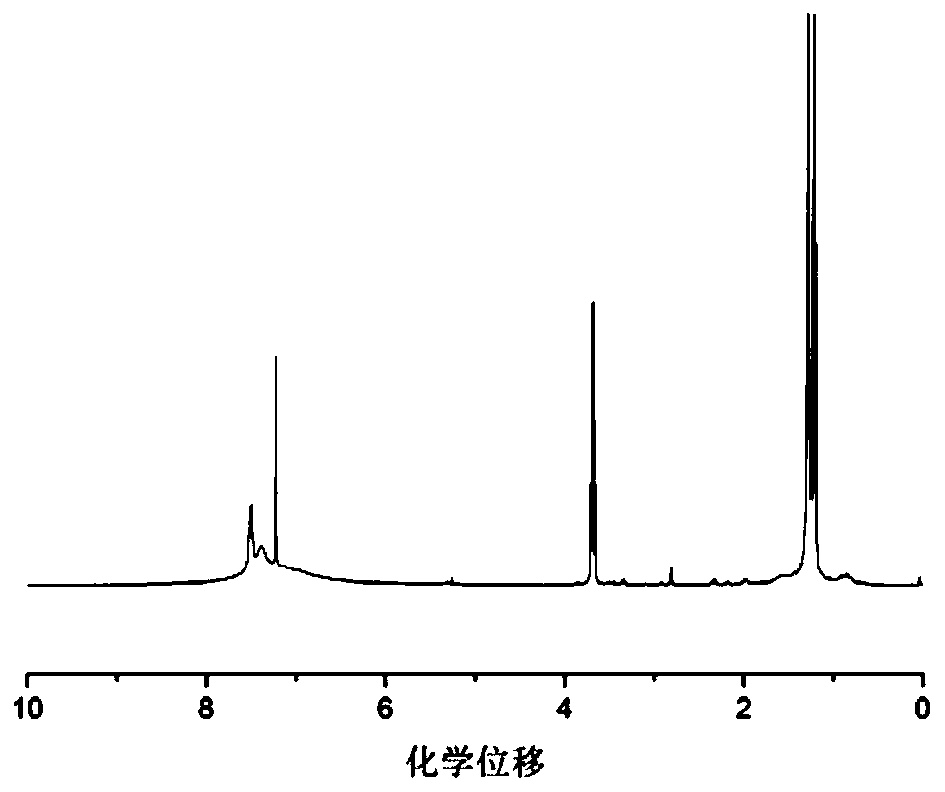

[0047] Specific embodiment 1: The triphenylamine-based benzothiadiazole polymer containing biphenyl structure in this embodiment is carbazolyl triphenylamino-benzothiadiazole polymer containing biphenyl structure, bis-4 containing biphenyl structure - tert-butyltriphenylaminobenzothiadiazole polymer or triphenylaminobenzothiadiazole polymer containing biphenyl structure;

[0048] Wherein the structural formula of the carbazolyl triphenylamino-benzothiadiazole polymer containing biphenyl structure is:

[0049] In the formula, n is a positive integer;

[0050] The structural formula of two 4-tert-butyltrianilinobenzothiadiazole polymers containing biphenyl structure is:

[0051] In the formula, n is a positive integer.

[0052] The structural formula of the triphenylamino-benzothiadiazole polymer containing biphenyl structure is:

[0053] In the formula, n is a positive integer.

[0054] This embodiment has the following beneficial effects:

[0055] 1. The triphenylam...

specific Embodiment approach 2

[0060] Specific embodiment two: the method for the triphenylamine benzothiadiazole polymer containing biphenyl structure in this embodiment is carried out according to the following steps:

[0061] 1. Preparation of benzothiadiazole derivatives:

[0062] Add the compound 4,7-dibromo-2,1,3-benzothiadiazole and n-butyllithium with a concentration of 1.6-1.7M to the degassed tetrahydrofuran at -79~-78°C, and heat up to Stir at -40°C for 3 to 4 hours under a nitrogen atmosphere, then cool down to -79 to -78°C, add tributyltin chloride, heat up to room temperature and stir for 17 to 18 hours, quench the reaction with water, use The organic phase was obtained by ether extraction, and anhydrous MgSO was added to the organic phase 4 After drying, the organic phase is evaporated under reduced pressure to obtain the benzothiadiazole derivative M1;

[0063] The molar volume ratio of compound 4,7-dibromo-2,1,3-benzothiadiazole to degassed tetrahydrofuran in step 1 is 0.2mmol:(19~20)mL:;...

specific Embodiment approach 3

[0073] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the preparation method of the degassed tetrahydrofuran described in step one is: vacuumize the three-neck round bottom flask filled with tetrahydrofuran with a vacuum pump, and then pass it into Nitrogen: Repeat vacuuming and feeding nitrogen 3 to 4 times. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com