Photochromic PVB film as well as preparation method and application thereof

A technology of photochromic and photochromic materials, applied in the direction of adhesives, film/sheet adhesives, film/sheet without carrier, etc., can solve the problem of photochromic window material limitation and avoid reaction Slow speed, strong anti-aging performance, and enhanced photochromic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

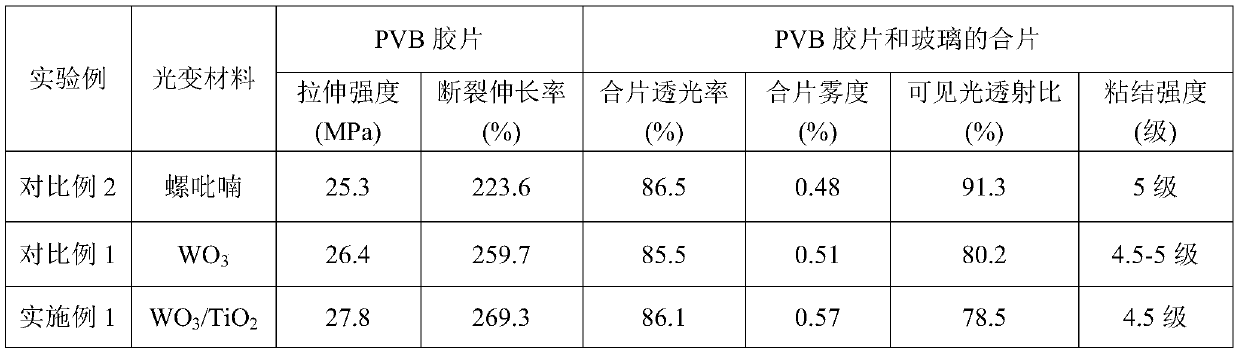

Embodiment 1

[0046] A photochromic PVB film, comprising the following raw materials:

[0047] PVB resin powder, plasticizer, antioxidant, UV absorber, silane coupling agent, adhesion modifier, WO 3 / TiO 2 Composite photochromic material.

[0048] Wherein, the PVB resin powder used has a hydroxyl content of 17-20wt%, a viscosity of 200-300cp (20°C), and a melt index (140°C / 21.6kg) of 0.8-1.2g / 10min.

[0049] The plasticizer used was triethylene glycol diisocaprylate (3GO plasticizer).

[0050] The antioxidant used is a mixture of antioxidant 1010 and antioxidant 168, and the mass ratio of antioxidant 1010 and antioxidant 168 is 1:1.

[0051] The UV absorber used is UV-326.

[0052] The silane coupling agents used are γ-glycidyl etheroxypropyl triethoxysilane (A-187) and β-(3,4, epoxycyclohexyl)-ethyltrimethoxysilane (A-186 ), the mass ratio of A-187 and A-186 is 1:1.

[0053] The cohesion regulator used is a mixture of magnesium acetate and potassium acetate, and the mass ratio of mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com