Intelligent industrial robot device for assembling automobile water pump impeller

A technology for industrial robots and water pump impellers, which is applied to the components of pumping devices for elastic fluids, machines/engines, pumps, etc., and can solve impeller wear, large press-fit interference, and poor flexibility of impeller automatic press-fit devices And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

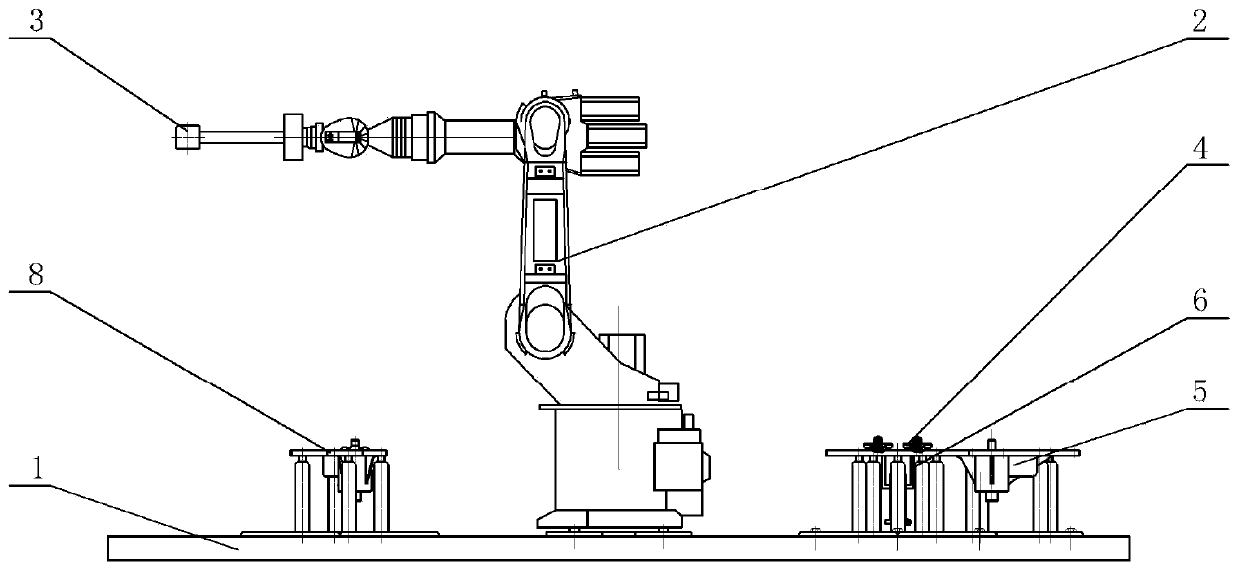

[0035]With reference to the accompanying drawings, an intelligent industrial robot device for assembly of an automobile water pump impeller includes a base 1, a robot arm 2, a gripper 3, an impeller loading station fixture 4, a water pump shell loading station fixture 5, and an impeller pre-installation tool. Position fixture 6, impeller pressing station fixture 7, and blanking station fixture 8, set the machine arm 2 on the base 1 and fix it on the base 1, set the gripper 3 on the front end of the upper part of the machine arm 2, set the 1 The upper right part is provided with the impeller loading station fixture 4, the water pump shell feeding station fixture 5, the impeller pre-installation station fixture 6, the impeller pressing station fixture 7 is set on the base, and the impeller pressing station fixture 7 is set on the base. The blanking station clamp 8 is set; the jaw 3 is composed of a connecting plate 3-1, a pressure sensor 3-2, a driver 3-3, an upper jaw 3-4, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com