Method and device for preparing steel/aluminum laminated composite plate by hot continuous rolling with small rolling reduction

A reduction and clad plate technology, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as uncoordinated deformation, large reduction in a single pass, and easy oxidation of the bonding interface, so as to avoid Large noise pollution, stable product performance, and reduced combination difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

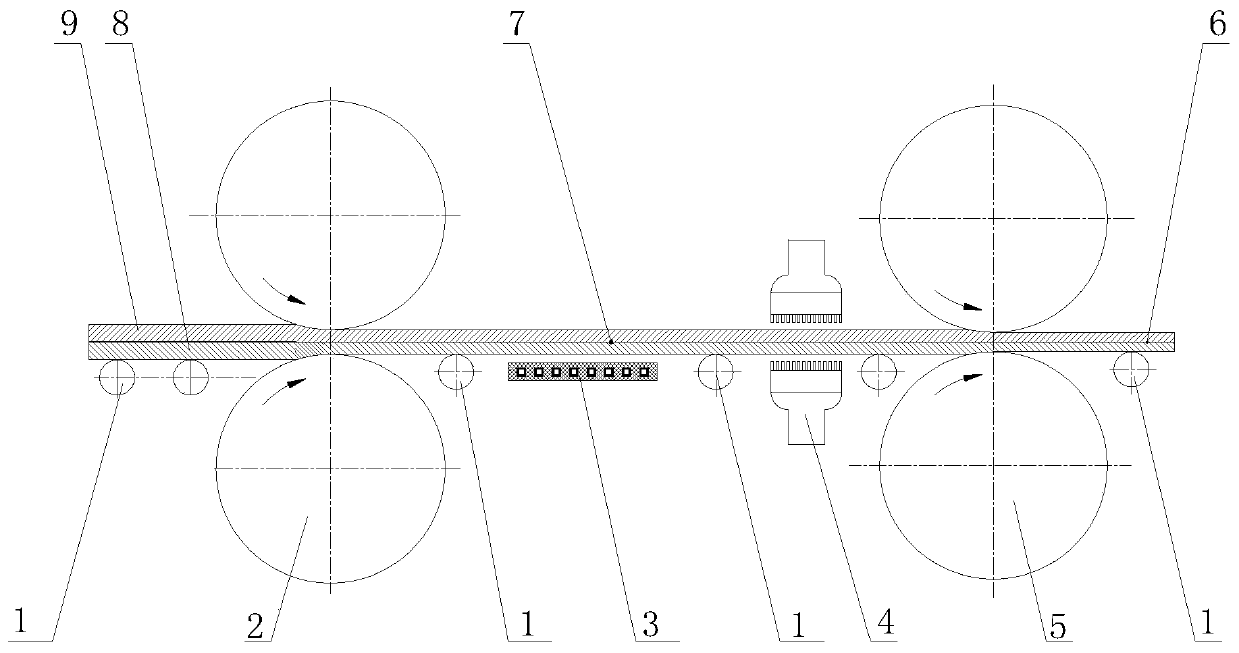

[0030] Such as figure 1 , figure 2 Shown, a kind of method for preparing steel / aluminum layered composite plate by cold-hot continuous rolling with small reduction, adopting this method to prepare Q235 / 3003 layered composite plate, comprises the following steps:

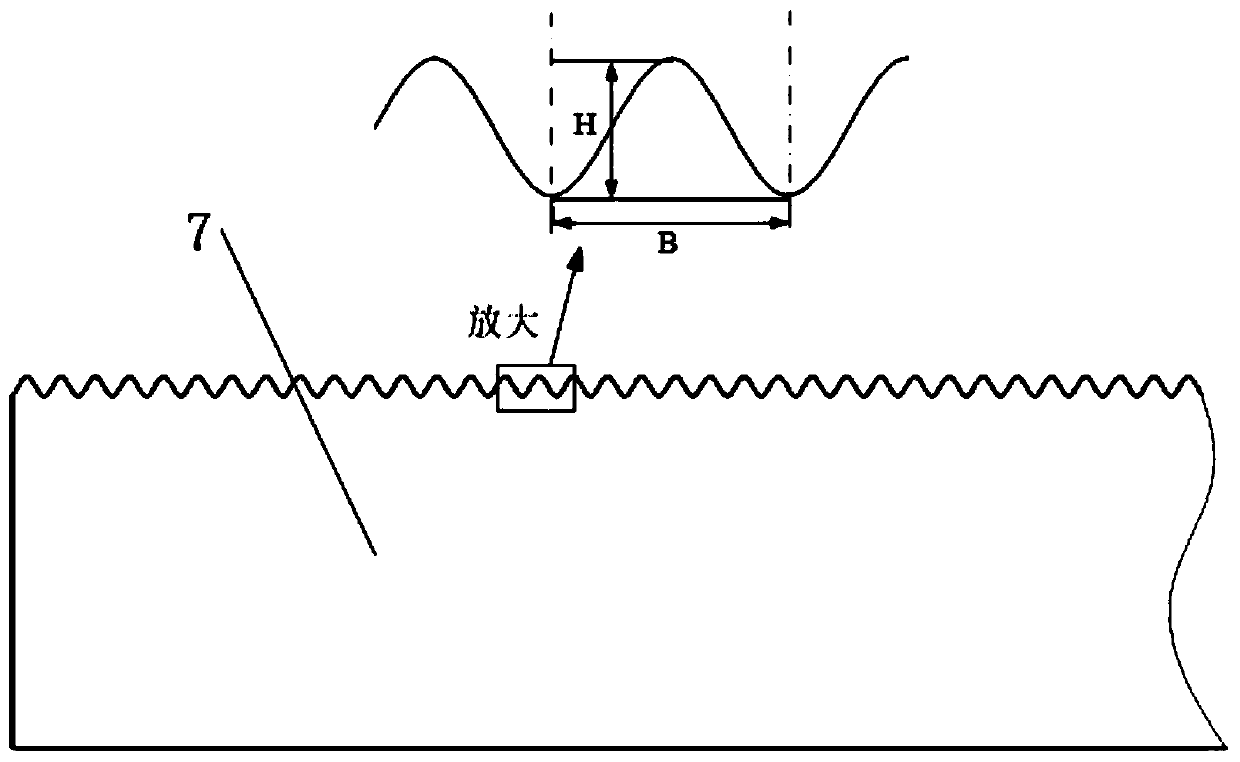

[0031] 1): Prepare a piece of Q235 steel plate 8 to be compounded with a length × width × height of 3000 × 400 × 14mm, and use a plastic forming method to prepare a corrugated surface from the surface to be compounded of the Q235 steel plate 8 to be compounded. The corrugation height H=2mm, the corrugation width B=4mm, air-cool the Q235 steel plate 8 to be compounded with the corrugated surface at 600° C. for 2 hours, and polish the corrugated surface of the Q235 steel plate 8 to be compounded with a grinder, remove oil stains and oxide films on the corrugated surface, and use acetone and Clean the corrugated surface with alcohol, let it stand and dry; select the 3003 aluminum alloy plate 9 to be compounded with a ...

Embodiment 2

[0040] Such as figure 1 , figure 2 Shown, a kind of method for preparing steel / aluminum layered composite plate by cold-hot continuous rolling with small reduction, adopting this method to prepare Q235B / 5083 layered composite plate, comprises the following steps:

[0041] 1): Prepare a piece of Q235B steel plate 8 to be compounded with a length × width × height of 6000 × 500 × 100 mm, and use a plastic forming method to prepare a corrugated surface on the surface of the Q235 B steel plate 8 to be compounded. The corrugation height H = 8mm, corrugated Width B=8mm, anneal the Q235B steel plate 8 to be compounded with the corrugated surface at 600°C for 2 hours, then air-cool, grind the corrugated surface of the Q235B steel plate 8 to be compounded with a grinder, remove the oil stain and oxide film on the corrugated surface, and use acetone Clean the corrugated surface with alcohol, let it stand and dry; select the 5083 aluminum alloy plate 9 to be compounded with a length × w...

Embodiment 3

[0049] Such as figure 1 , figure 2 Shown, a kind of method for preparing steel / aluminum layered composite plate by cold-hot rolling with small reduction, adopting this method to prepare 304 / 1060 layered composite plate, comprises the following steps:

[0050] 1): Prepare a 304 stainless steel plate 8 to be compounded with a length × width × height of 12000 × 1000 × 3mm, and use a plastic forming method to prepare a corrugated surface on the surface of the 304 stainless steel plate 8 to be compounded, and the corrugation height H = 0.3mm , Corrugation width B=1.5mm, the 304 stainless steel plate 8 to be compounded with the corrugated surface was annealed at 600° C. for 2 hours and air-cooled, and the corrugated surface of the 304 stainless steel plate 8 to be compounded was polished with a grinder, and the oil and dirt on the corrugated surface were removed. Oxide film, clean the corrugated surface with acetone and alcohol, let it stand and dry; select the 1060 industrial pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com