Application of expansion type water pressure and air pressure linkage seal for pressure engineering

An expansion-sealing and expansion-type technology, which is applied in the field of water-cooled sealing in plug-in pressure vessels, can solve the problems of inconvenient operation, bulkiness, and inability to ensure the locking effect, and achieve the effect of easy control and convenient balance management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

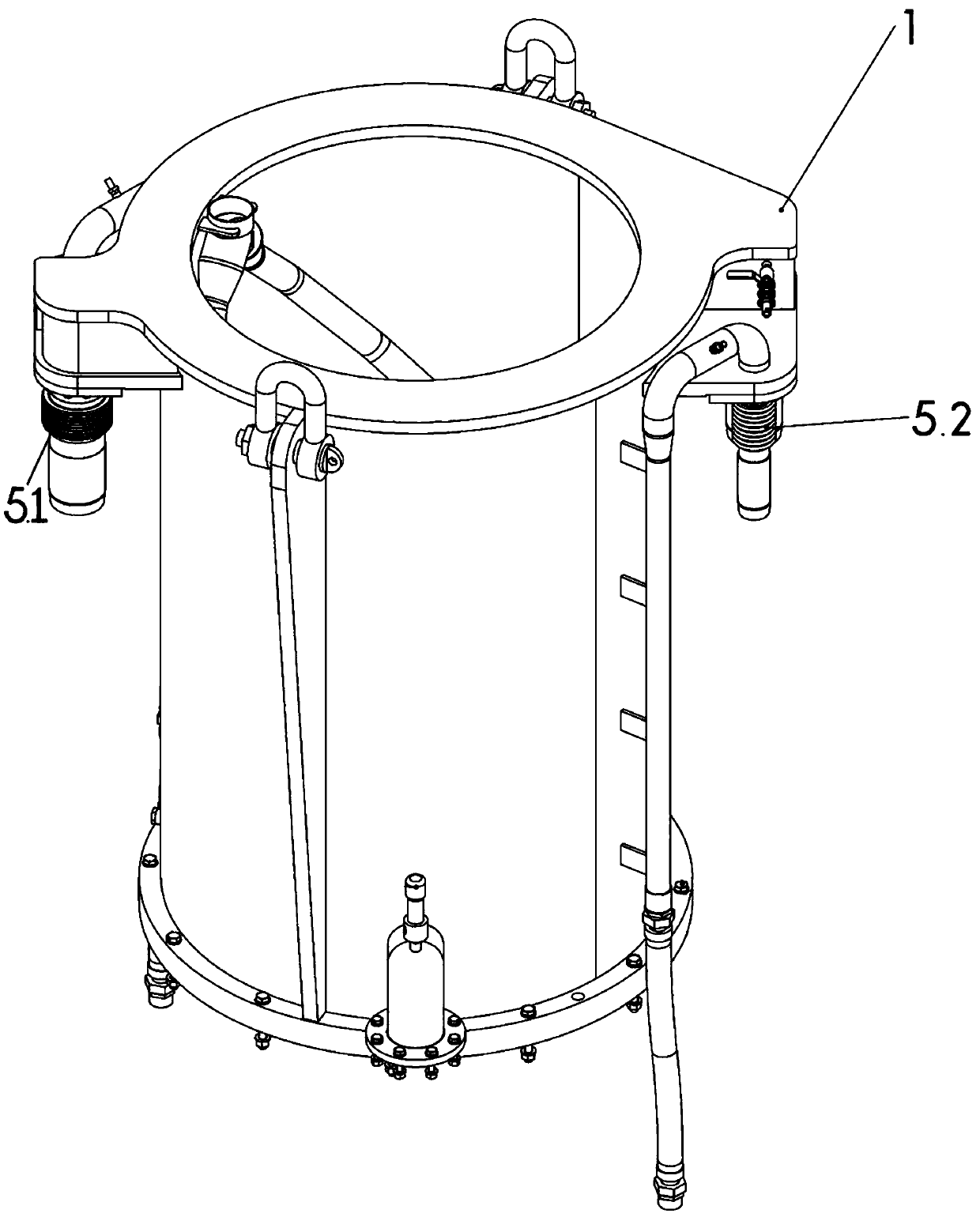

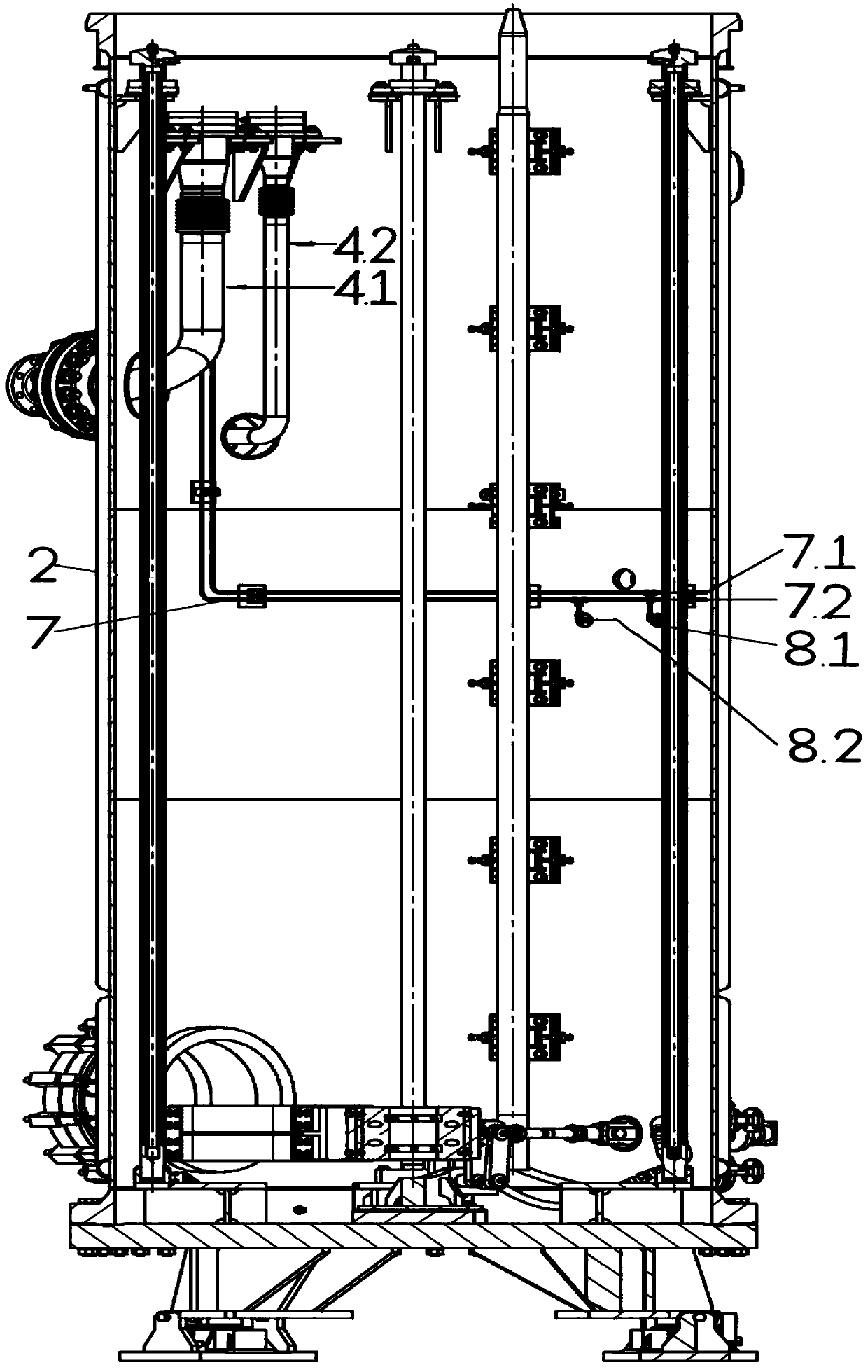

[0025] First, hoist the crystallizer 1 into the pressure tank 2, insert the large water inlet pipe 5.1 and the small water inlet pipe 5.2 of the crystallizer 1 with position compensation into the large pipe connection of the corresponding waterway in the pressure tank 2 slowly The water jacket 4.1 and the small pipe are connected to the water jacket 4.2, and the low-pressure water pump is used to feed water; the gas pipeline 7.1 leading to the first expansion seal and the gas pipeline 7.2 leading to the second expansion seal are activated to feed the first The first expansion seal 6.1, and the second expansion seal 6.2 are inflated and sealed to complete the sealing of the waterway.

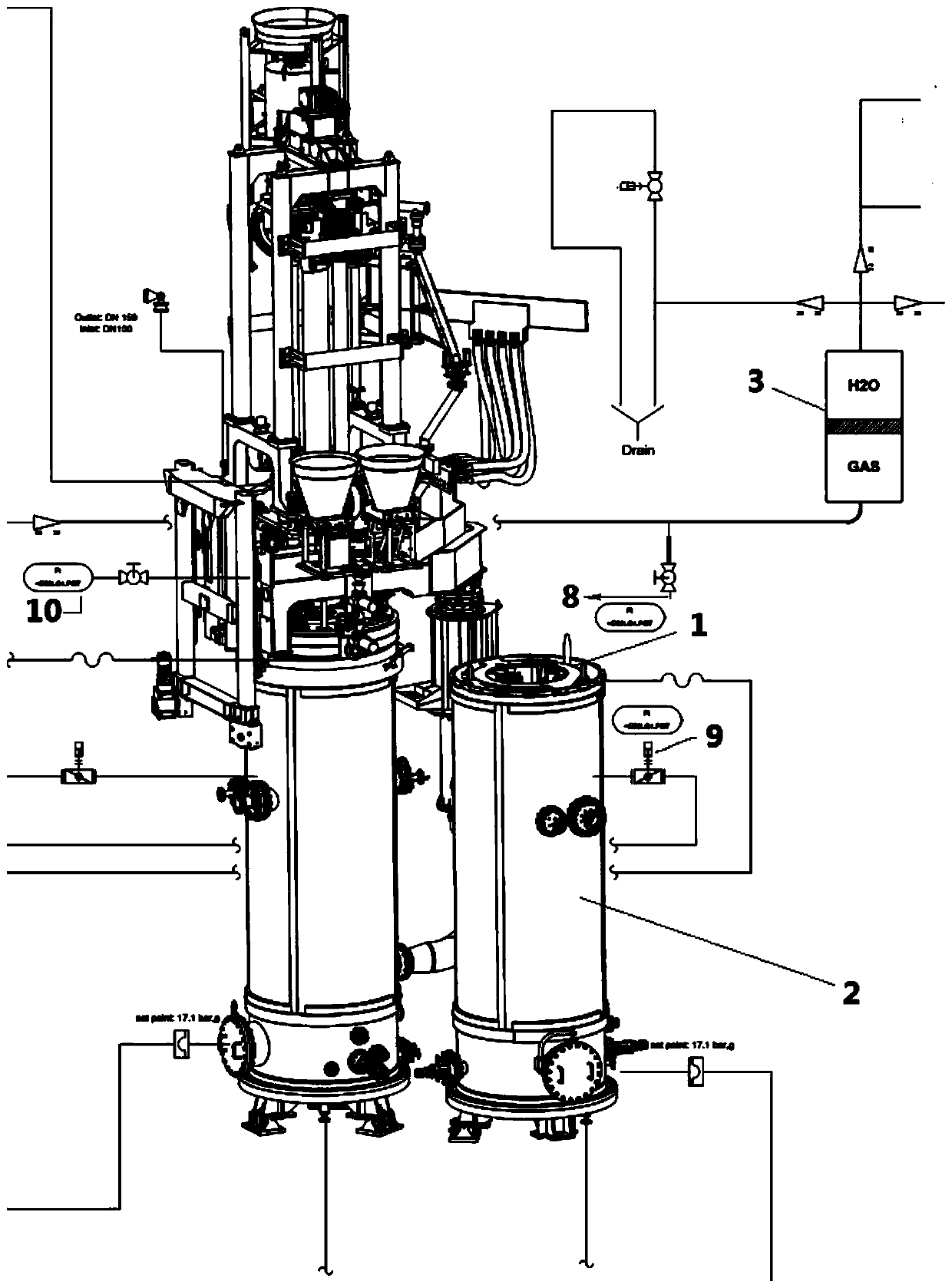

[0026] Then start the valve as needed to fill the pressure tank 2 with high-pressure gas, and the high-pressure water system starts. The pressure tank 2 is provided with a gas pressure detection device 10 in the tank, and the water system is provided with a water pipeline water pressure detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com