External corrosion prevention integrated equipment for oil-water well pipeline

A technology for oil-water wells and pipelines, which is applied in the direction of pipeline anticorrosion/rust protection, pipeline protection, mechanical equipment, etc. It can solve the problems of anticorrosion quality decline, manual transfer without stable speed, safety, quality hidden dangers, etc., to achieve lap width Uniform and stable, beneficial to labor protection and avoiding mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

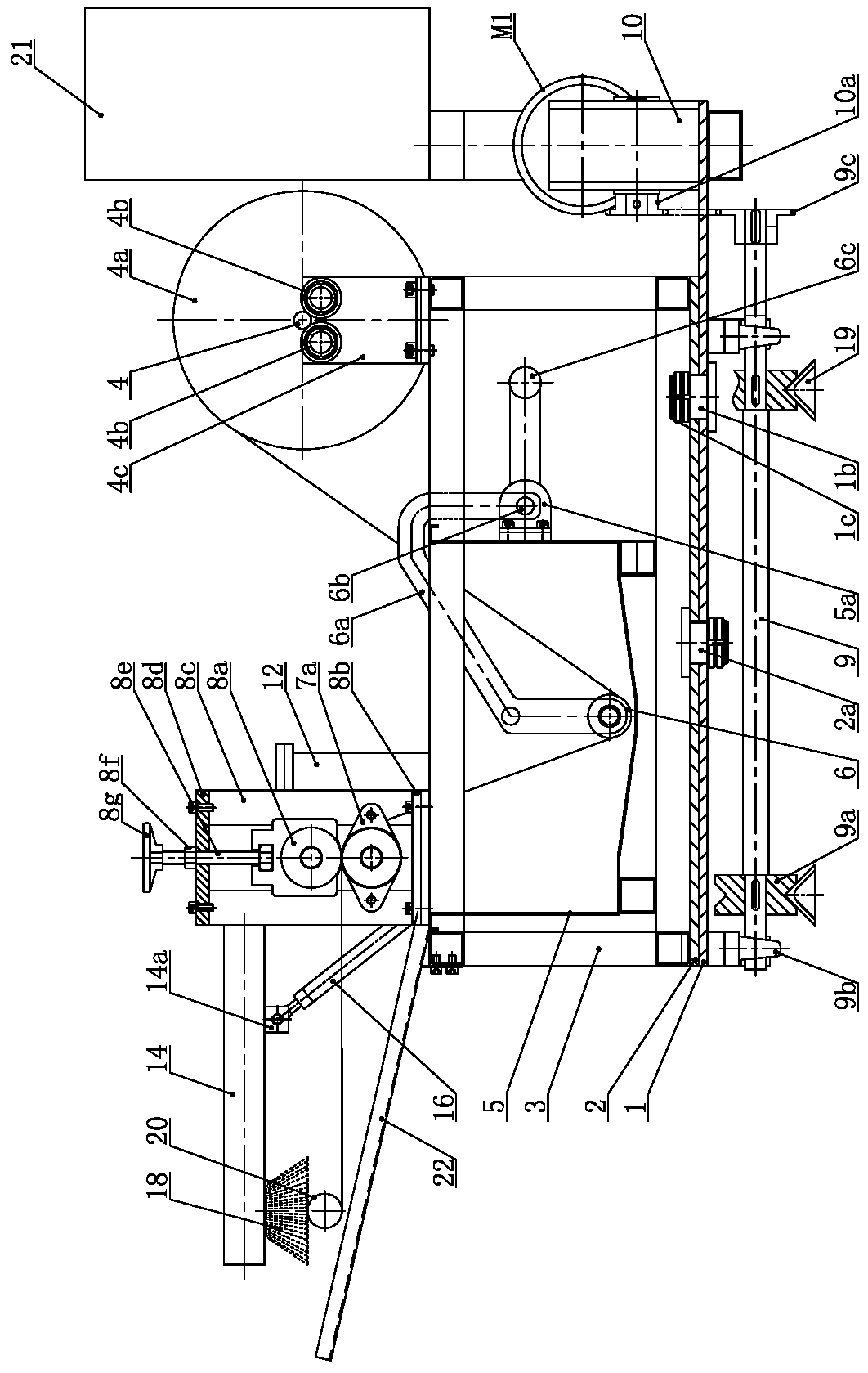

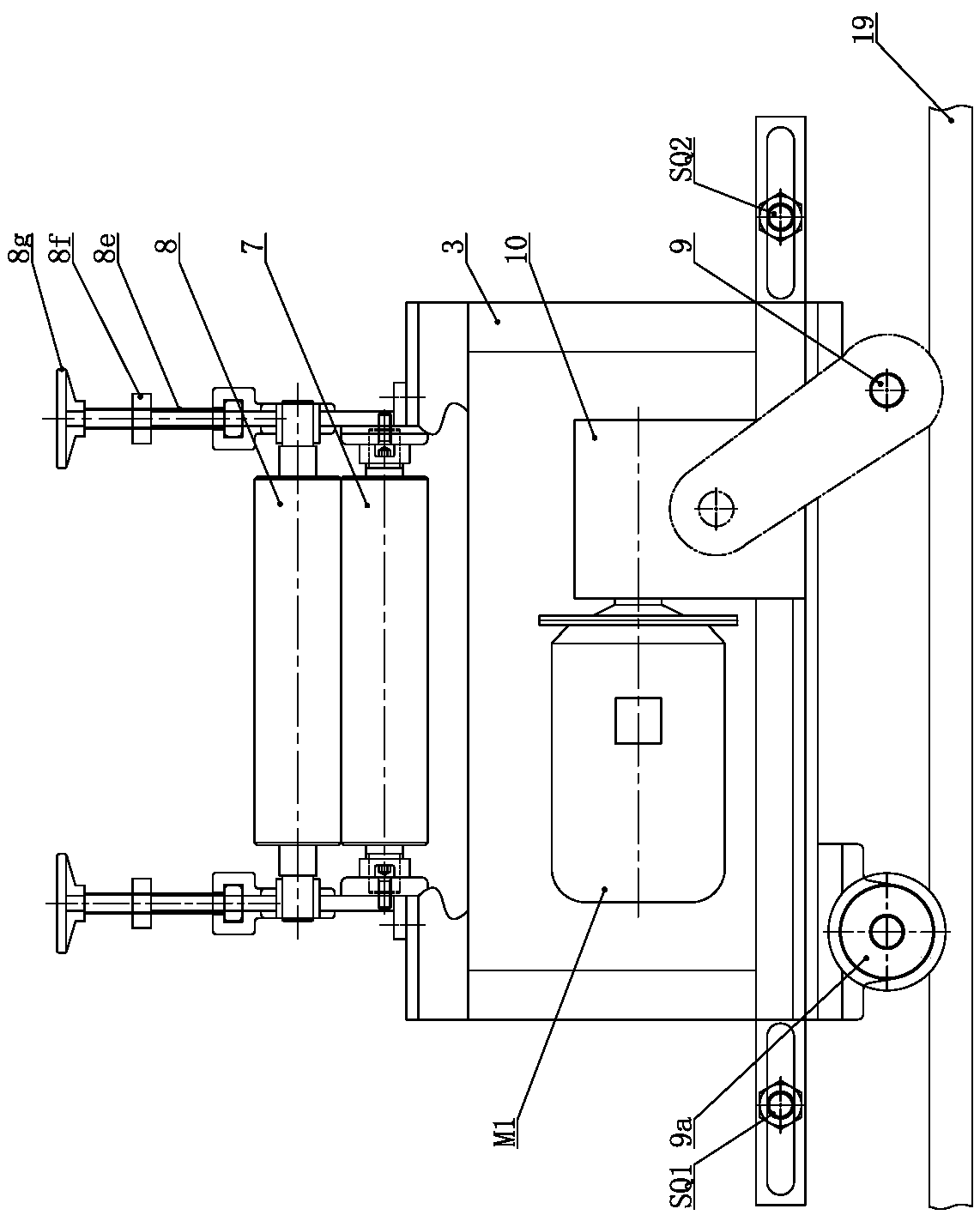

[0030] like Figure 1 to Figure 6 As shown, the anti-corrosion integrated equipment outside the oil-water well pipeline of the present invention includes an X-guiding rail 19 extending in the left and right directions parallel to the oil-water well pipeline 20, and two X-guiding rails 19 are parallel to each other and fixed on the ground behind the oil-water well pipeline 20 On, two X guide rails 19 are supported with a fixed base plate 1 that can advance along the guide rails, the fixed base plate 1 is hinged with a movable base plate 2, and an asphalt paint dipping tank 5 is fixed above the middle part of the movable base plate 2, the rear of the pitch paint dipping tank 5 There is a cloth roll 4 extending along the X direction, and a glass fiber cloth roll 4a is wound on the cloth roll 4, a cloth roll 6 is arranged in the asphalt paint dipping tank 5, and a pair of rolls are arranged in front of the pitch paint dipping tank 5 After the glass fiber cloth drawn from the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com