TPU synthetic leather and preparation method thereof

A technology of synthetic leather and mixture, which is applied in the direction of textiles and papermaking, can solve the problems of surface wear, poor wear resistance of products, poor wear resistance, etc., and achieve the effect of improved durability, high resilience, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

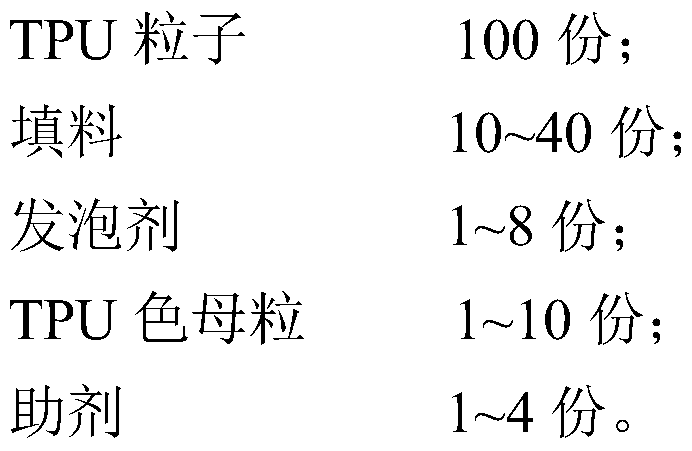

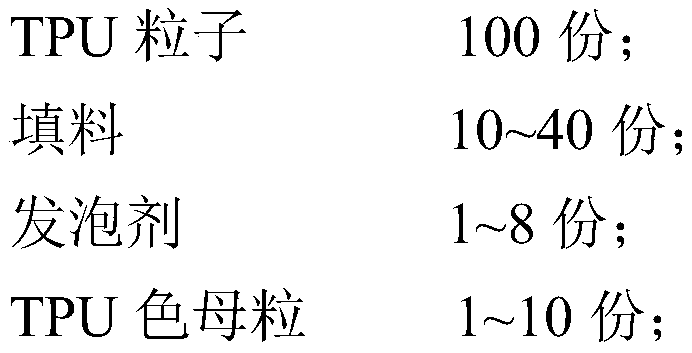

[0030] A preparation method of TPU synthetic leather, comprising the following steps:

[0031] (1) Weigh TPU particles, fillers, foaming agents, TPU color masterbatches, and additives according to the proportion, add them to the internal mixer, and mix them evenly;

[0032] (2) Transfer the well-mixed mixture to an internal mixer to mix it evenly, then transfer it all to an open mill, carry out kneading, make it further mixed, reach a plasticized state, and stop kneading;

[0033] (3) Transfer the material in the plasticized state obtained in step 2) to the calender, adjust the thickness of the film to reach the required thickness, and the thickness of the film is 0.2mm;

[0034] (4) Laminating the prepared base cloth;

[0035] (5) Foaming and embossing the laminated film to obtain the desired product.

Embodiment 1

[0037] Weigh 150KG of polyester TPU particles with a hardness of 75A, 30KG of calcium carbonate, 9KG of AC foaming agent, 6KG of TPU color masterbatch, and 3KG of PE wax additive according to the proportion, put them into the internal mixer, and mix them evenly. Then, transfer all the materials to the open mill, carry out the open mill, and after reaching the plasticized state, transfer it to the calender, adjust the required thickness to 0.2mm, and paste the prepared base cloth, and paste it The combined film is foamed and sucked to obtain the finished product. The number of times of its wear resistance reaches 5000 revolutions (H-18 grinding wheel, 2KG, TABER wear tester).

Embodiment 2

[0039] Weigh 150KG of polyester TPU particles with a hardness of 70A, 45KG of calcium carbonate, 8KG of AC foaming agent, 7KG of TPU color masterbatch, and 4KG of PE wax additive according to the proportion, put them into the internal mixer, and mix them evenly. Then, transfer all the materials to the open mill, carry out the open mill, and after reaching the plasticized state, transfer it to the calender, adjust the required thickness to 0.2mm, and paste the prepared base cloth, and paste it The combined film is foamed and sucked to obtain the finished product. The number of times of wear resistance reaches 4800 revolutions (H-18 grinding wheel, 2KG, TABER wear tester).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com