Multi-stage hydraulic oil cylinder with improved structure

A structure improvement, hydraulic cylinder technology, applied in the direction of engine sealing, fluid pressure actuating device, engine components, etc., to achieve good sealing effect, good wear resistance, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

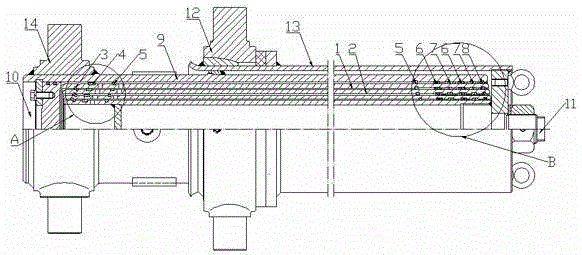

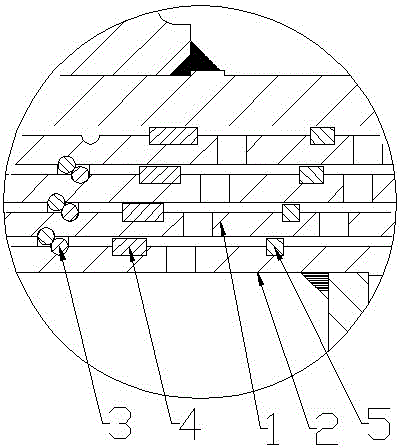

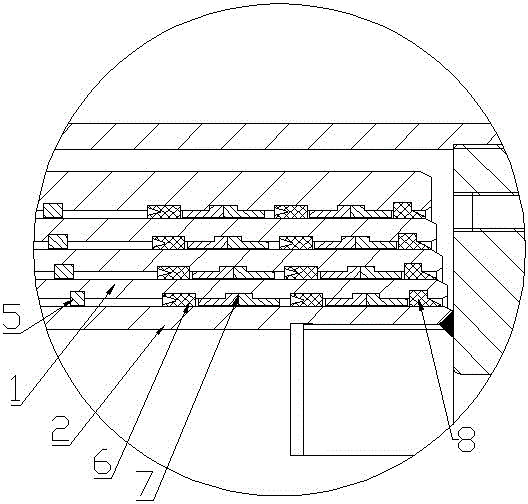

[0014] Such as figure 1 , figure 2 with image 3 As shown, a multi-stage hydraulic cylinder with improved structure includes a cylinder retraction limit assembly 3, a cylinder tail end guide ring 4, Oil cylinder lifting limit assembly 5, oil cylinder seal ring 6, oil cylinder front end guide ring 7 and dustproof ring 8; figure 2 As shown, the oil cylinder retraction limit assembly 3 is composed of two steel wire retaining rings, one of which is fixed in the inner ring groove at the tail end of the outer oil cylinder 1, and the other steel wire retaining ring is fixed at the end of the next stage oil cylinder 2 In the outer ring groove, when the oil cylinder is retracted and limited, it is limited by the contact of two steel wire retaining rings. The steel wire retaining ring is made of 65Mn material, and the diameter of the steel wire is 5 mm; figure 2 The guide ring 4 at the end of the oil cylinder shown is made of polyurethane material, and the guide ring 4 at the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com