Preparation method of high-wear-resistance and high-corrosion-resistance protective layer of hot work die steel

A hot work die steel, high wear-resistant technology, applied in the field of die steel, can solve the problem of the decrease of the bonding strength between the coating and the base material, and achieve the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

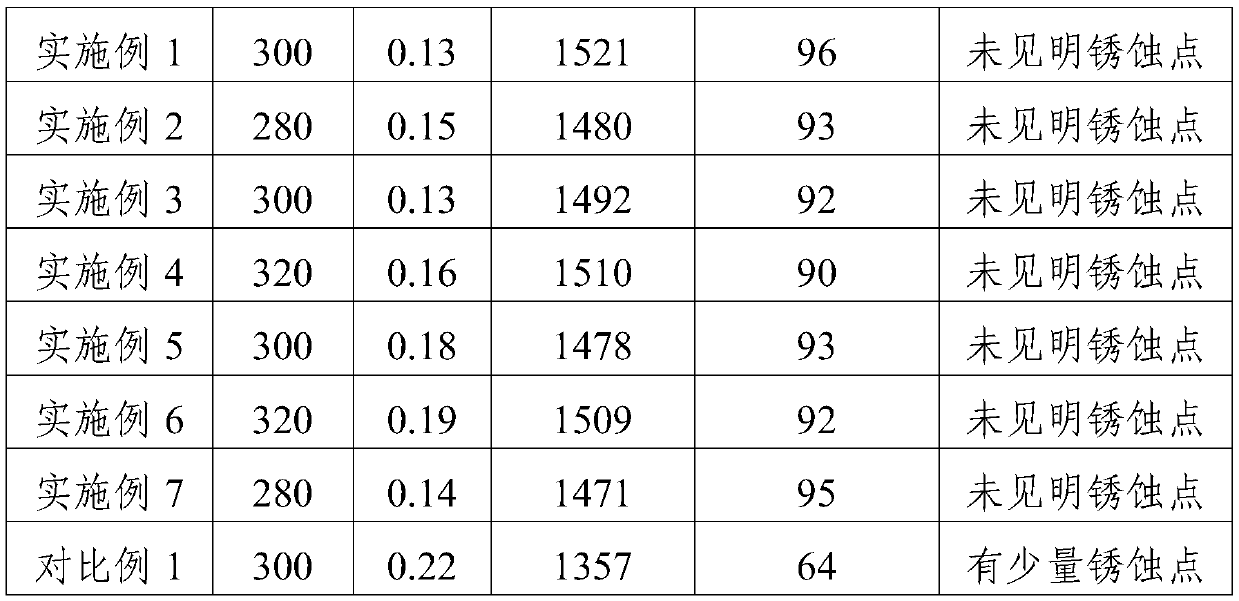

Embodiment 1

[0031] A method for preparing a high wear-resistant and high-corrosion protective layer of hot work die steel 4Cr5MoSiV1, comprising the following steps:

[0032] (1) Put the hot-working die steel in absolute ethanol, clean it with an ultrasonic cleaner for 40 minutes, take it out, and dry it; then use a sandblasting machine to perform sandblasting of brown corundum.

[0033] (2) Preheat the hot work die steel treated in step (1) to make the surface temperature reach 220°C, then spray a layer of coating on the surface of the die steel by supersonic flame spraying method, and use compressed air to cool after spraying , the coating thickness is 300μm; the process parameters of the supersonic flame spraying method are: oxygen flow rate 300L / min, propane flow rate 80 L / min, powder feeding rate 42g / min, spraying distance 260mm.

[0034] The spraying powder is composed of the following components by weight: WC: 60%, TaC: 15%, VC: 4%, Nano Y 2 o 3 : 1.1%, the balance being NiCr.

...

Embodiment 2

[0039] A method for preparing a high wear-resistant and high-corrosion protective layer of hot work die steel 5CrMnMoSiV, comprising the following steps:

[0040] (1) Put the hot-working die steel in absolute ethanol, use an ultrasonic cleaner to clean it for 40 minutes, take it out, and dry it; then use a sandblasting machine to perform sandblasting of brown corundum;

[0041] (2) preheating the hot work die steel treated in step (1) to make the surface temperature reach 230°C, then spray a layer of coating on the surface of the die steel by supersonic flame spraying method, and use compressed air to cool after spraying, The thickness of the coating is 280 μm; the process parameters of the supersonic flame spraying method are: oxygen flow rate 260L / min, propane flow rate 80 L / min, powder feeding rate 38g / min, spraying distance 280mm.

[0042] The spraying powder is composed of the following components by weight: WC: 62%, TaC: 14%, VC: 4%, Nano Y 2 o 3 : 0.8-1.5%, the balanc...

Embodiment 3

[0047] A method for preparing a high wear-resistant and high-corrosion protective layer of hot work die steel 4Cr5MoSiV1, comprising the following steps:

[0048] (1) Put the hot-working die steel in absolute ethanol, clean it with an ultrasonic cleaner for 40 minutes, take it out, and dry it; then use a sandblasting machine to perform sandblasting of brown corundum.

[0049] (2) Preheat the hot work die steel treated in step (1) to make the surface temperature reach 230°C, then spray a layer of coating on the surface of the die steel by supersonic flame spraying method, and use compressed air to cool after spraying , the coating thickness is 300 μm; the process parameters of the supersonic flame spraying method are: oxygen flow rate 320L / min, propane flow rate 82 L / min, powder feeding rate 40g / min, spraying distance 240mm.

[0050] The spraying powder is composed of the following components by weight: WC: 64%, TaC: 12%, VC: 4%, Nano Ce 2 o 3 : 0.8%, the balance being NiCr. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com