Silver-tarnishing prevention agent

A technology of discoloration agent and wetting agent, applied in the direction of metal material coating process, can solve the problems of high cost, pollution, complex process of electroplating precious metals, etc., and achieve the effect of low cost, simple operation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

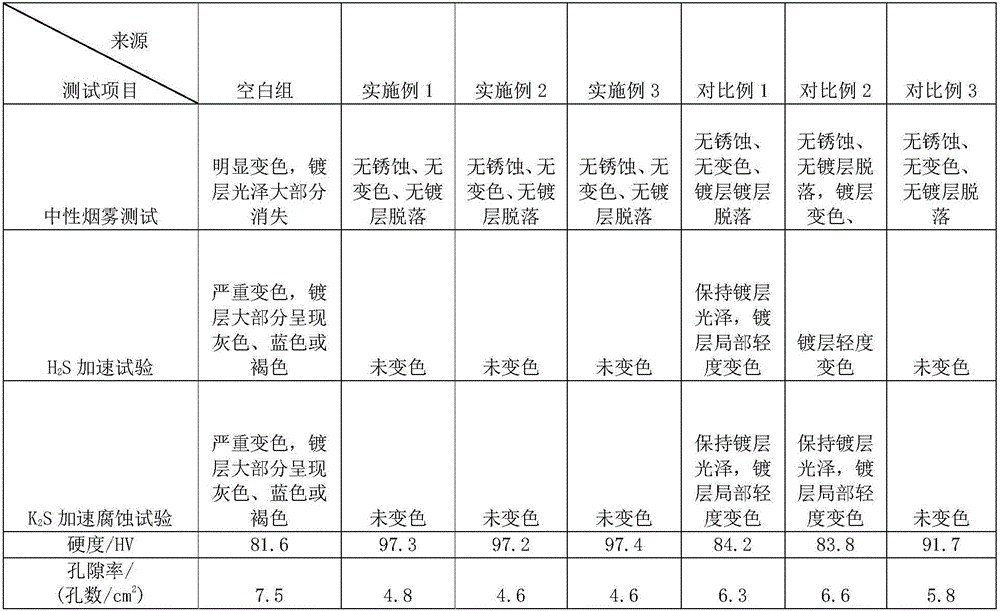

Examples

Embodiment 1

[0022] Anti-silver discoloration agent, which is: 4.2 g of tert-dodecyl mercaptan, 0.64 g of N-sulfathiazole thioglycolic acid, 1.8 g of benzotriazole, 0.2 g of morpholine, 4.2 g of nonylphenol polyoxyethylene ether g, 0.217 g of 2-hydroxy-4-n-octyloxybenzophenone, 0.143 g of 2-benzotriazol-2-yl-4,6-bis-tert-butylphenol, and 48 g of ethylene glycol.

[0023] The preparation method of the anti-silver discoloration agent is:

[0024] A: take 4.2g of tertiary dodecyl mercaptan, 1.8g of benzotriazole, 4.2g of nonylphenol polyoxyethylene ether and 31.2g of ethylene glycol to obtain composition A; take N-sulfathiazole thioglycolic acid 0.64g, morpholine 0.2g, 2-hydroxy-4-n-octyloxybenzophenone 0.217g, 2-benzotriazol-2-yl-4,6-bis-tert-butylphenol 0.143g and ethylene glycol 16.8g obtained composition B;

[0025] B: The composition A was mixed at a temperature of 75°C and stirred for 15 minutes at a rotational speed of 550 rpm;

[0026] C: After heating the composition B to 60° C., ...

Embodiment 2

[0028] Anti-silver discoloration agent: 5.4 g of n-octadecyl mercaptan, 0.51 g of N-sulfathiazole thioglycolic acid, 1.5 g of benzotriazole, 0.4 g of morpholine, 3.6 g of octylphenol polyoxyethylene ether g, 2-hydroxy-4-n-octyloxybenzophenone 0.227g, 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl )-5-octyloxyphenol 0.283g and ethylene glycol 57g.

[0029] The preparation method of the anti-silver discoloration agent is:

[0030] A: Take 5.4 g of n-octadecyl mercaptan, 1.5 g of benzotriazole, 3.6 g of octylphenol polyoxyethylene ether and 37.05 g of ethylene glycol to obtain composition A; take N-sulfathiazole thioglycolic acid 0.51g, morpholine 0.4g, 2-hydroxy-4-n-octyloxybenzophenone 0.227g, 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5- Triazin-2-yl)-5-octyloxyphenol 0.283g and ethylene glycol 19.95g obtained composition B;

[0031] B: The composition A was mixed at a temperature of 75°C and stirred at a speed of 580 rpm for 12 minutes;

[0032] C: After heating the compositio...

Embodiment 3

[0034] Anti-silver discoloration agent: 1.537 g of tert-dodecyl mercaptan, 3.263 g of n-octadecyl mercaptan, 0.56 g of N-sulfathiazole thioglycolic acid, 1.68 g of benzotriazole, and nonylphenol Polyoxyethylene ether 1.846g, octylphenol polyoxyethylene ether 2.054g, morpholine 0.28g, 2-hydroxy-4-n-octoxybenzophenone 0.237g, 2-(4,6-bis(2,4 -Dimethylphenyl)-1,3,5-triazin-2-yl)-5-octyloxyphenol 0.213g and ethylene glycol 51g.

[0035] The preparation method of the anti-silver discoloration agent is:

[0036] A: Take 1.537 g of tert-dodecyl mercaptan, 3.263 g of n-octadecyl mercaptan, 1.68 g of benzotriazole, 1.846 g of nonylphenol polyoxyethylene ether, and 2.054 g of octylphenol polyoxyethylene ether and ethylene glycol 33.15g to obtain composition A; take N-sulfathiazole thioglycolic acid 0.56g, morpholine 0.28g, 2-hydroxy-4-n-octyloxybenzophenone 0.237g, 2-(4,6 -bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl)-5-octyloxyphenol 0.213g and ethylene glycol 17.85g to obtain compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com