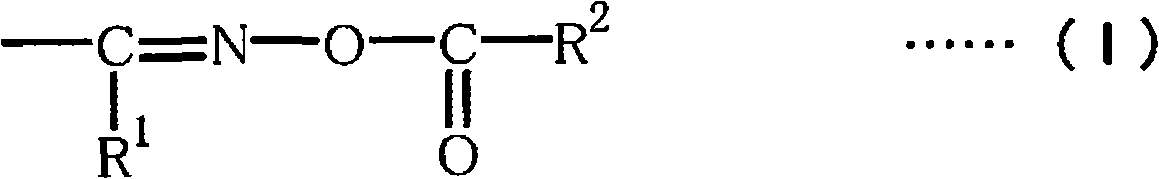

Photocuring resin composition, dry film, curing product and print circuit board

A technology of photocurable resin and composition, which is applied in the secondary treatment of printed circuit, optics, organic chemistry, etc. It can solve the problems of copper discoloration, discoloration, and difference in ultraviolet wavelength distribution, etc., and achieve the effect of inhibiting discoloration and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0180] The present invention will be specifically described below by showing Examples and Comparative Examples, but of course the present invention is not limited to the following Examples.

Synthetic example 1

[0182] 660 g of cresol novolak type epoxy resin (manufactured by Nippon Kayaku Co., Ltd., EOCN-104S, softening point 92° C., epoxy equivalent 220), 421.3 g of carbitol acetate, and 180.6 g of solvent naphtha were heated and stirred at 90° C. to dissolve. Next, it was cooled to 60° C., 216 g of acrylic acid, 4.0 g of triphenylphosphine, and 1.3 g of methylhydroquinone were added, and reacted at 100° C. for 12 hours to obtain a reaction product having an acid value of 0.2 mgKOH / g. 241.7 g of tetrahydrophthalic anhydride was added thereto, heated to 90° C., and reacted for 6 hours. Thus, a solution of a carboxylic acid-containing resin (A) having an acid value of 50 mgKOH / g, a double bond equivalent (g weight per mol of unsaturated group resin) of 400, and a weight average molecular weight of 7,000 was obtained. Hereinafter, this carboxylic acid resin-containing solution is referred to as A-1 varnish.

[0183] Coordination example and embodiment

[0184]The various component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com