Flexiblel ight-emitting unit and its making process

A manufacturing method and a flexible technology, which are applied to semiconductor devices of light-emitting elements, lighting devices, components of lighting devices, etc., can solve the problem of unsatisfactory lighting effects, difficulties in the direction of light sources of LED lighting components 2 being in the same direction, and LED luminous body It is not easy to install and fix, etc., to achieve the best tensile strength and flexibility, easy to install and fix, fast and easy to insert and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

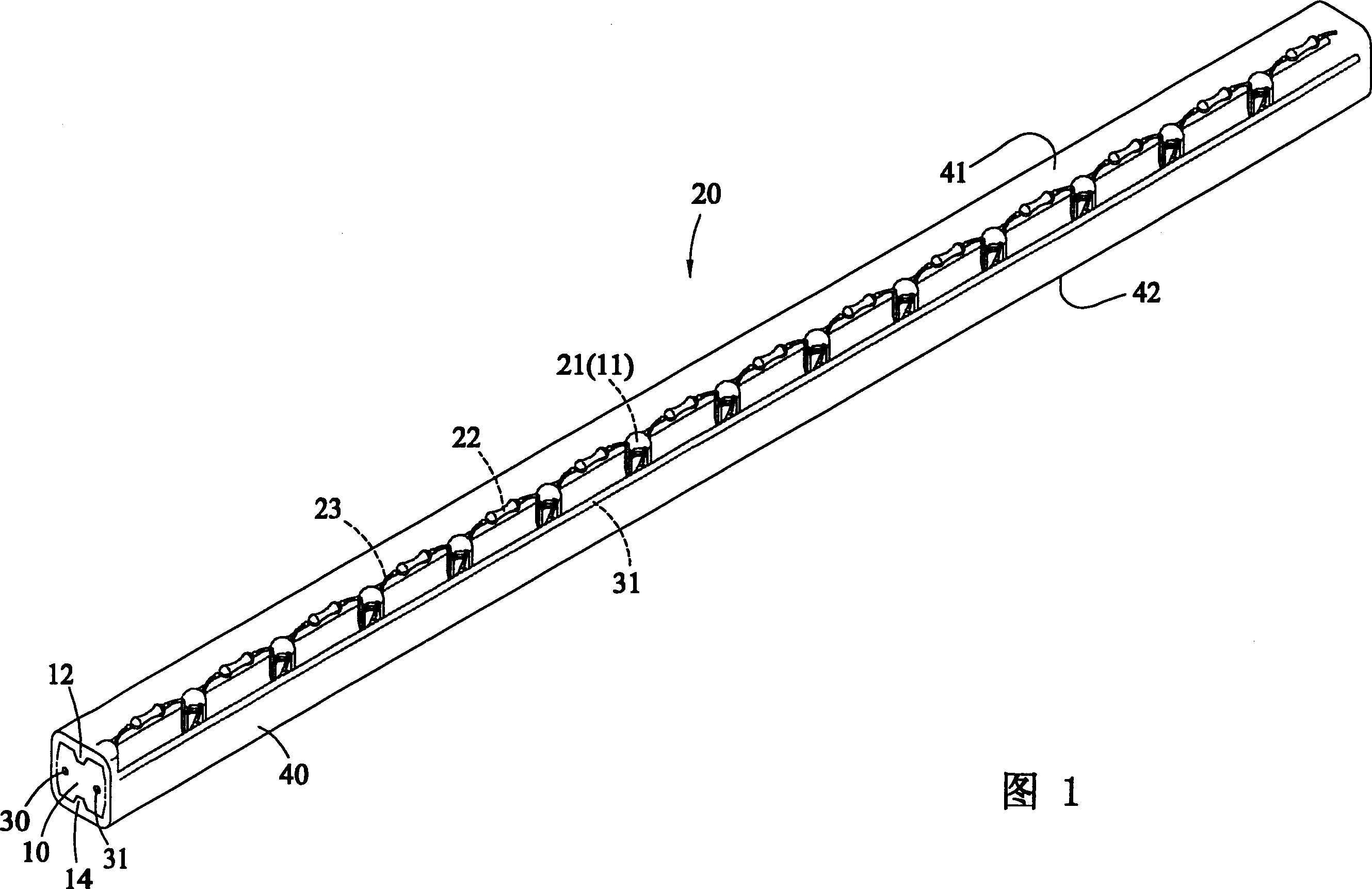

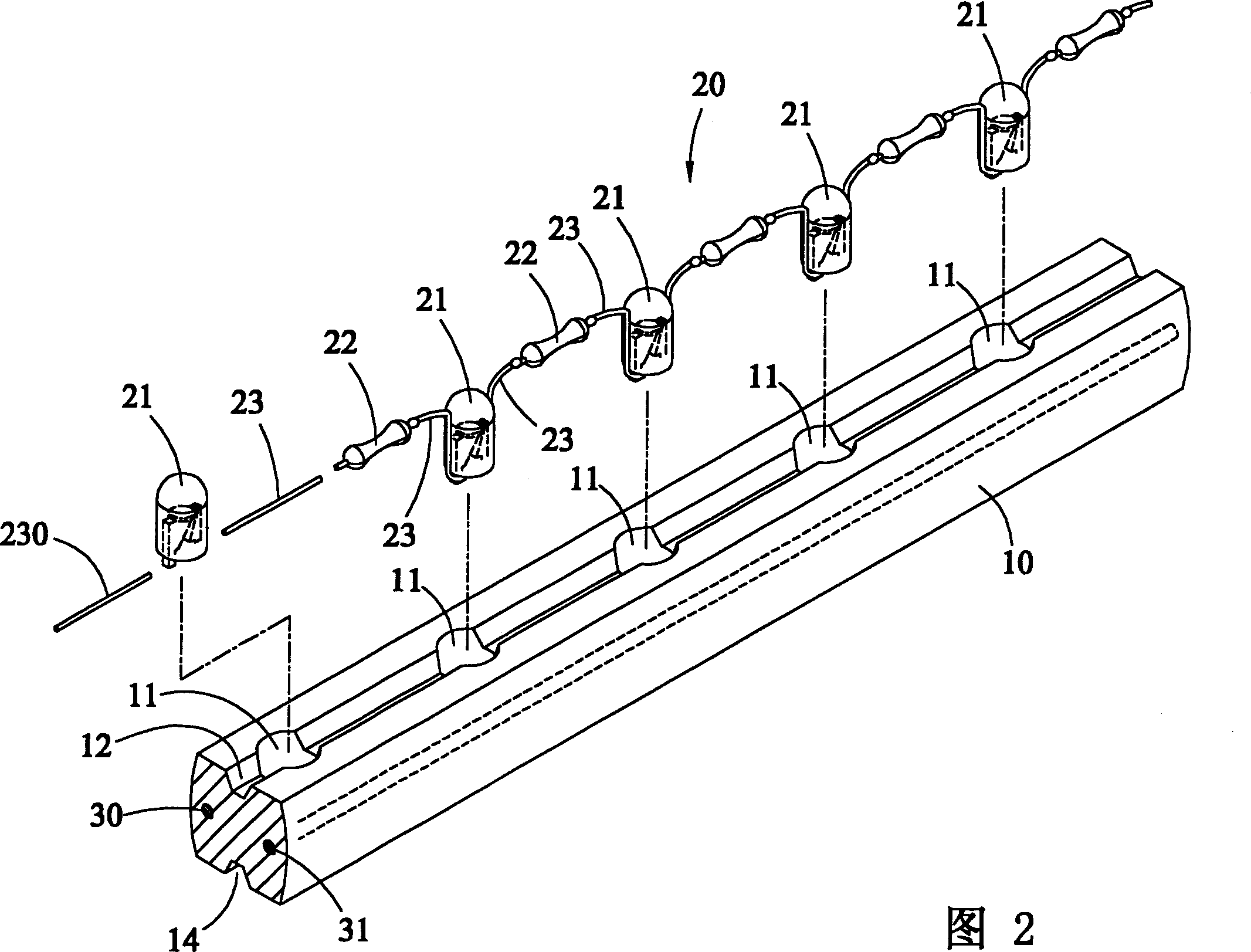

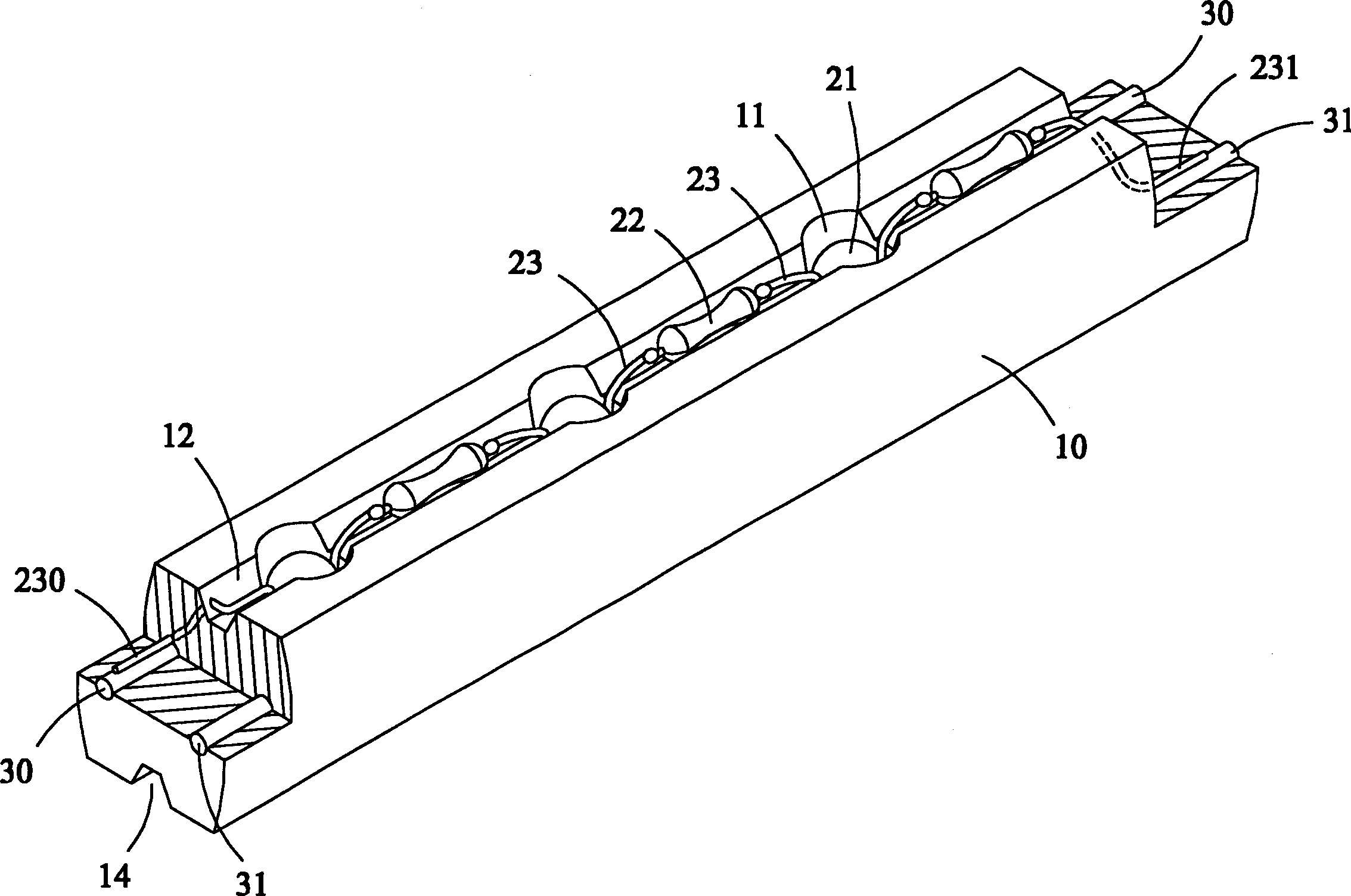

[0037] Figure 1 to image 3 As shown, the device of the present invention includes an inner layer fixing seat 10, an LED light string group 20, a pair of main wires 30, 31, and an outer layer fixing body 40; wherein, the inner layer fixing seat 10, the LED light string Group 20, the three-dimensional diagram of the main lines 30, 31, and the outer layer of fixed body 40, etc., as shown in Figure 1; the detailed three-dimensional decomposition of the LED light string group 20 and the inner layer of the fixing seat 10, as shown in Figure 2 ; Part of the three-dimensional representation of the LED lamp string group 20 arranged on the inner layer fixing base 10, as shown in detail image 3 Shown:

[0038] The inner layer fixing seat 10 is a strip-shaped transparent or translucent colloid, and several fixing holes 11 are equidistantly arranged, the top surface has an upper groove 12, and the bottom surface also has a lower groove 14, so that The inner layer fixing seat 10 forms a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com