Device and method for preparing titanium oxide nanorods by using waste denitration catalyst

A denitration catalyst and titanium oxide technology, applied in the field of denitration catalyst, can solve the problems of resource waste, environmental pollution, etc., and achieve the effects of improving the purging effect, reducing the excessive purging intensity, high efficiency and high value utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

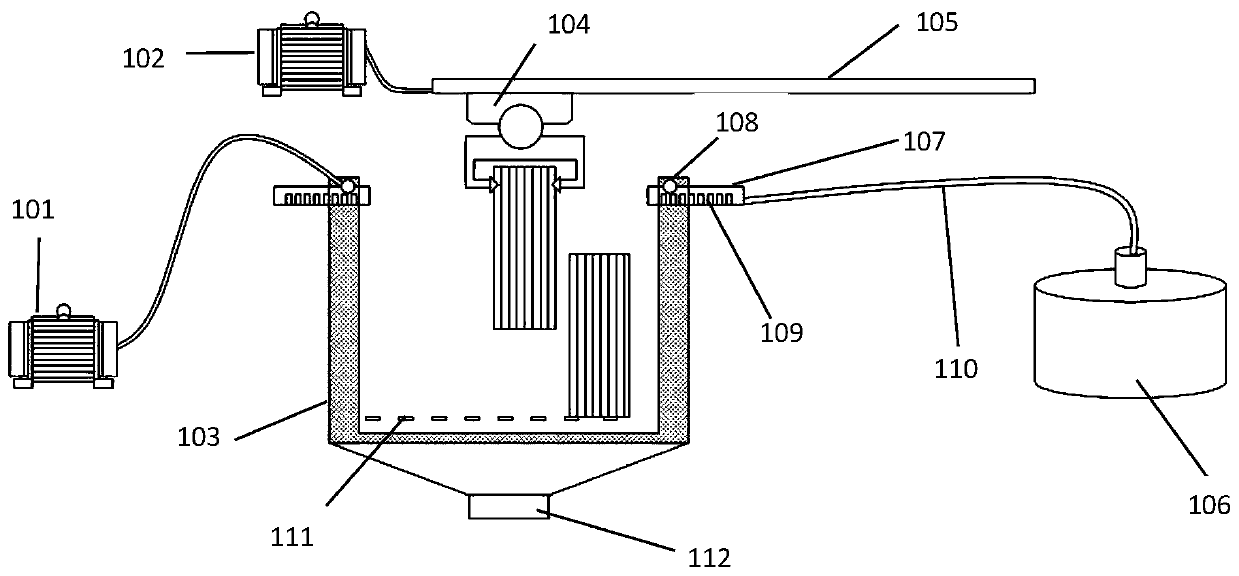

[0072] (1) Fix the denitration catalyst upright on the power-assisted manipulator of the compressed air purge device, and then purge it with compressed air at 0.5MPa for 60 minutes;

[0073] (2) Put the purged catalyst into a pickling device containing 50% acetic acid mass concentration for pickling for 6 hours, the volume ratio of the catalyst to the weak acid is 1:20; and use a constant temperature heating device to control the temperature at 30°C ;

[0074] (3) Put the acid-washed catalyst into a rinsing device for rinsing for 20 minutes, and then dry it at 110° C. for 2 hours;

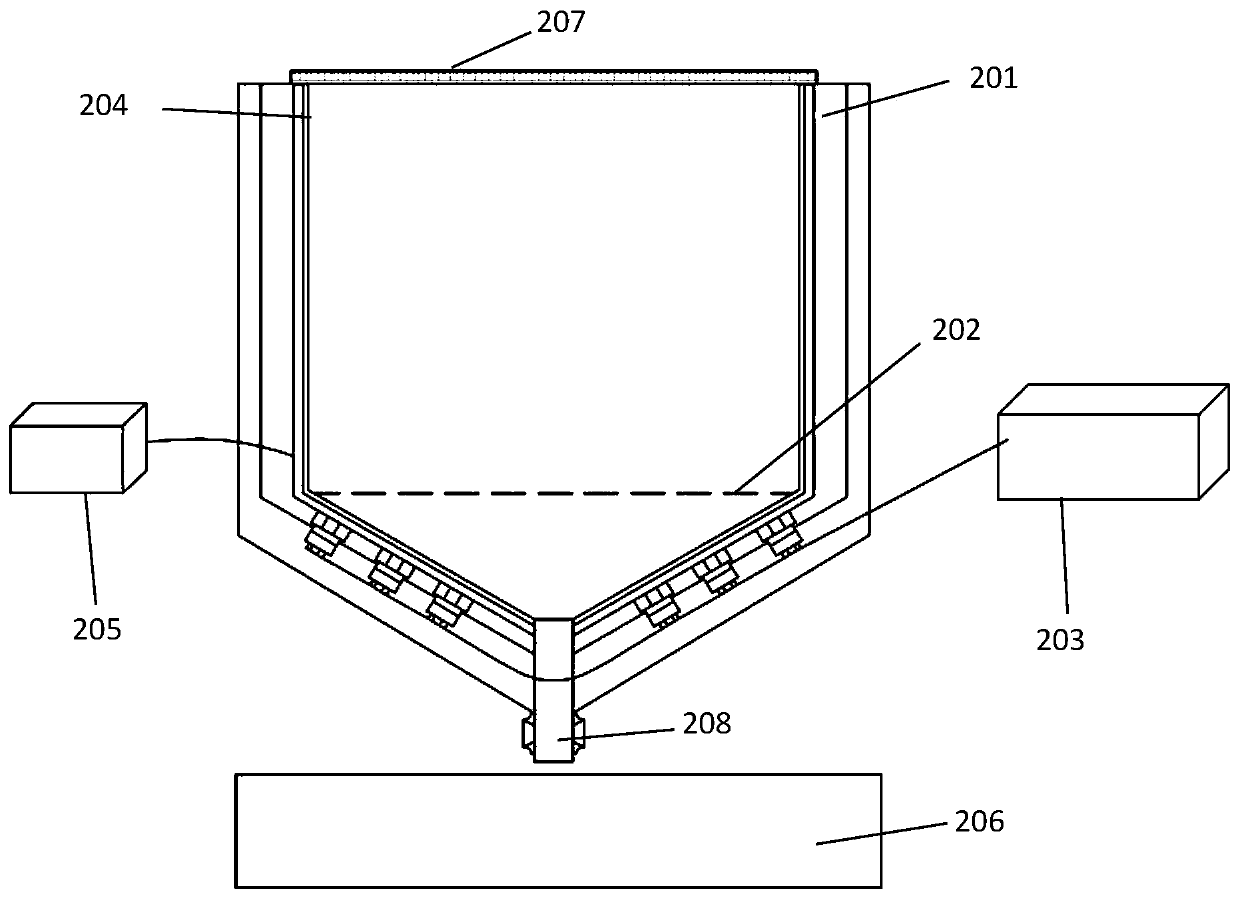

[0075] (4) Put the dried catalyst into a crushing device and crush it through a 20mm sieve, then put it into a grinding device and grind it through a 200 μm sieve to obtain a catalyst powder;

[0076] (5) Put the catalyst powder obtained in step (4) into the first reaction kettle and wash it with 10% ammonia water, the mass ratio of the catalyst powder to ammonia water is 1:20, and then carry out ...

Embodiment 2

[0080] (1) Fix the denitration catalyst upright on the power-assisted manipulator of the compressed air purge device, and then purge it with compressed air at 1MPa for 30min;

[0081] (2) put the catalyst after purging into a pickling device containing citric acid mass concentration fraction of 5% for pickling for 12h, the volume ratio of the catalyst to the weak acid is 1:10; and use a constant temperature heating device to control the temperature at 50 ℃;

[0082] (3) Put the acid-washed catalyst into a rinsing device for rinsing for 30 minutes, and then dry it at 100° C. for 5 hours;

[0083] (4) Put the dried catalyst into a crushing device and crush it through a 20mm sieve, then put it into a grinding device and grind it through a 200 μm sieve to obtain a catalyst powder;

[0084] (5) Put the catalyst powder obtained in step (4) into the first reaction kettle and wash it with 25% ammonia water, the mass ratio of the catalyst powder to ammonia water is 1:5, and then carry...

Embodiment 3

[0088] (1) Fix the denitration catalyst upright on the power-assisted manipulator of the compressed air purge device, and then purge it with compressed air at 0.7MPa for 45min;

[0089] (2) the catalyst after purging is put into the pickling device that contains hydrobromic acid mass concentration fraction and carry out pickling 9h, the volume ratio of catalyst and weak acid is 1:15; And adopt constant temperature heating device to control temperature at 45°C;

[0090] (3) Put the acid-washed catalyst into a rinsing device for rinsing for 25 minutes, and then dry it at 105° C. for 3 hours;

[0091] (4) Put the dried catalyst into a crushing device and crush it through a 20mm sieve, then put it into a grinding device and grind it through a 200 μm sieve to obtain a catalyst powder;

[0092] (5) Put the catalyst powder obtained in step (4) into the first reaction kettle and wash it with 15% ammonia water, the mass ratio of the catalyst powder to ammonia water is 1:12, and then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com