Optical glass polishing device

A technology of optical glass and polishing device, which is applied in the direction of grinding drive device, grinding/polishing equipment, surface polishing machine tool, etc., can solve the problems of inability to polish optical glass, inconvenient fixing of optical glass, insufficient polishing, etc., and achieve improvement The effect of polishing degree, convenient fixing and convenient flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

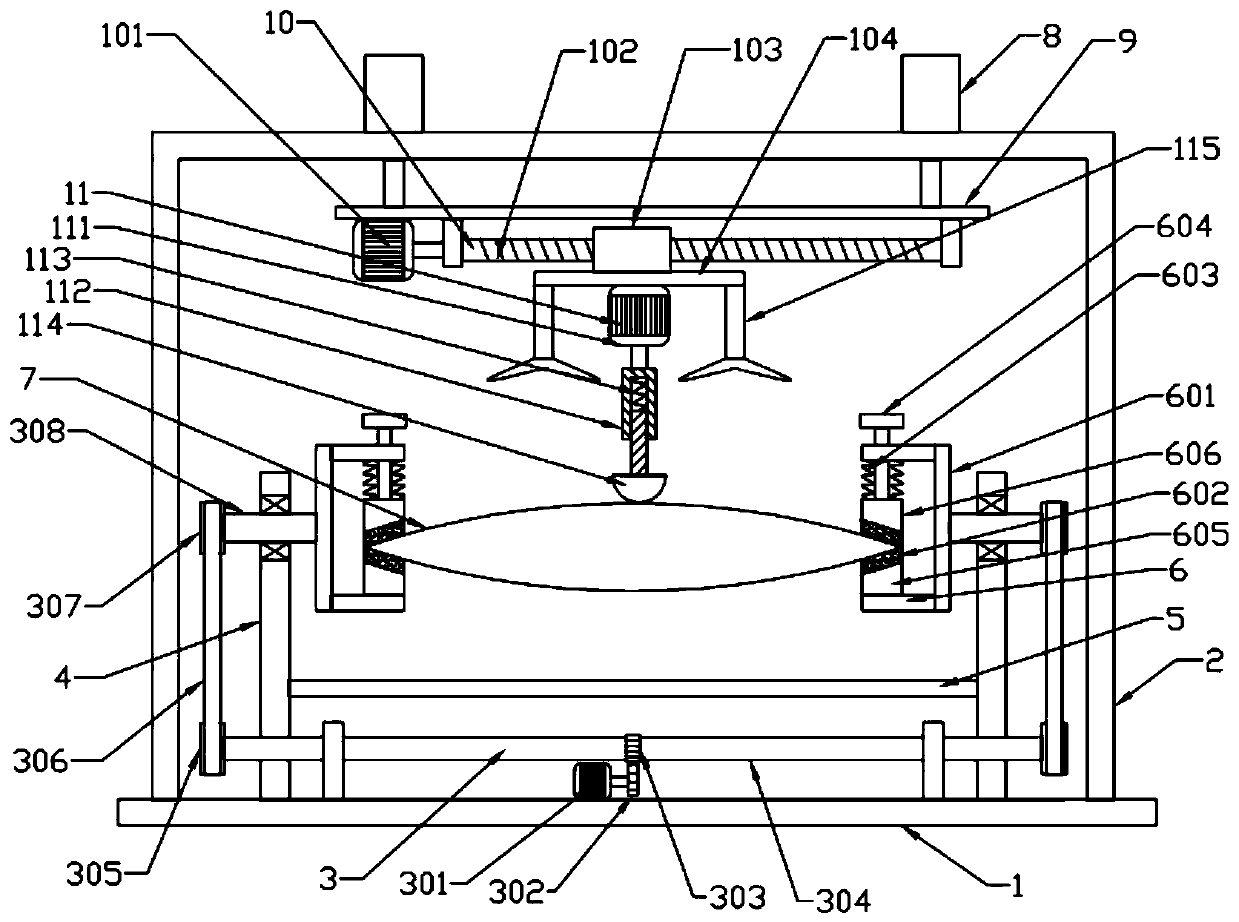

[0019] see Figure 1~2 , in an embodiment of the present invention, an optical glass polishing device includes a base 1, and a turning mechanism 3 is installed on the base 1, and the turning mechanism 3 includes: a first motor 301, a first gear 302, and a second gear 303 , the first rotating shaft 304, the driving wheel 305, the transmission belt 306, the driven wheel 307 and the second rotating shaft 308, the first rotating shaft 304 is installed on the base 1, and a driving wheel is symmetrically installed at the left and right ends of the first rotating shaft 304 305, a driven wheel 307 is respectively installed above the two driving wheels 305, the driving wheel 305 and the driven wheel 307 are rotationally connected by a transmission belt 306, and the two driven wheels 307 are respectively installed on a second rotating shaft 308 , the left and right sides of the base 1 are respectively equipped with a vertical plate 4 for installing the second rotating shaft 308, an impu...

Embodiment 2

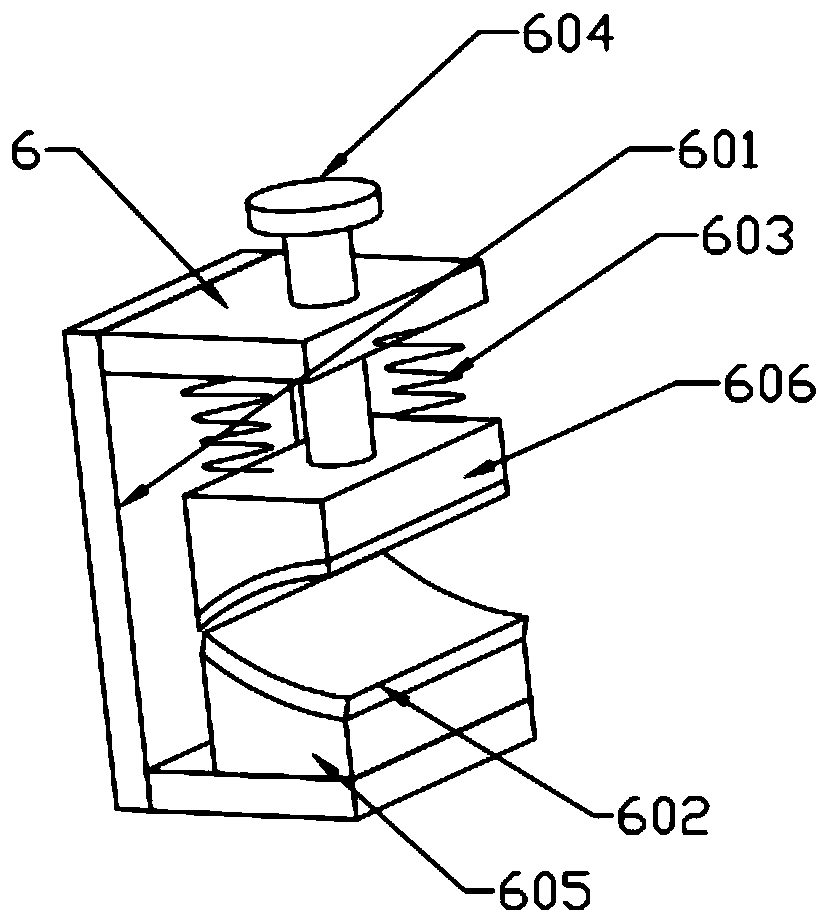

[0021] see Figure 1~2 , in the embodiment of the present invention, the clamping mechanism 6 includes: a main body frame 601, a protective cover 602, a first spring 603, a clamp 604, a lower clamping block 605 and an upper clamping block 606, the inside of the main body frame 601 A lower clamping block 605 is installed at the bottom, and an upper clamping block 606 used in conjunction with it is installed above the lower clamping block 605. The upper clamping block 606 is connected to the main body frame 601 through a plurality of first springs 603. A protective sleeve 602 is installed on the lower block 605 and the upper block 606 , and the clamp 604 for pushing the upper block 606 is installed on the main body frame 601 .

[0022] In this optical glass polishing device, the two ends of the curved optical glass 7 are respectively placed in a clamping mechanism 6, and the upper block 606 is driven to move downward by rotating the clamp 604, and the curved optical glass 7 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com