Auxiliary tooling for grinding machine processing

A technology for auxiliary tooling and grinding machines, which is applied in the direction of grinding machines, metal processing equipment, grinding workpiece supports, etc. It can solve the problems of not meeting the needs of users, unable to load and unload workpieces, affecting the practicality of grinding machines and working efficiency, etc. , to achieve the effect of reducing processing difficulty and convenient fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

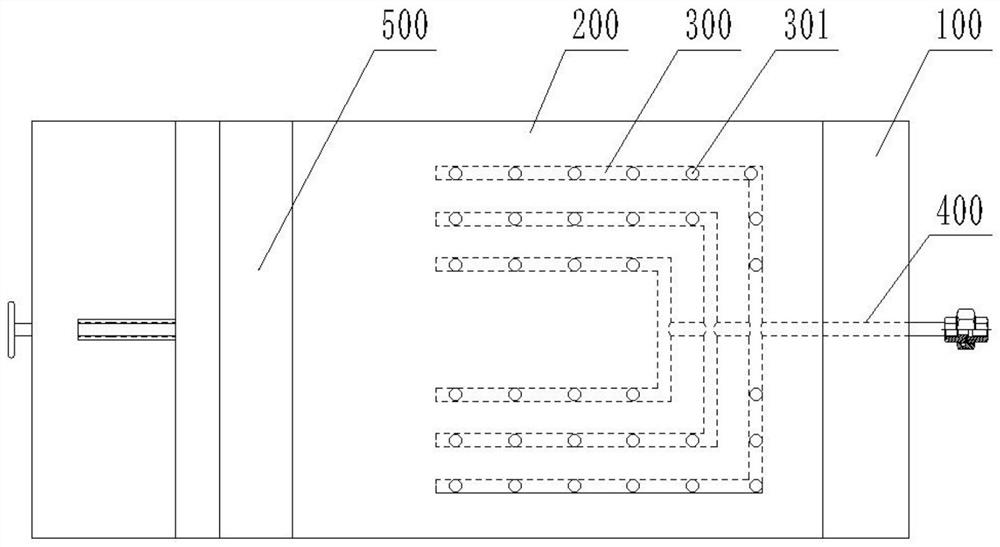

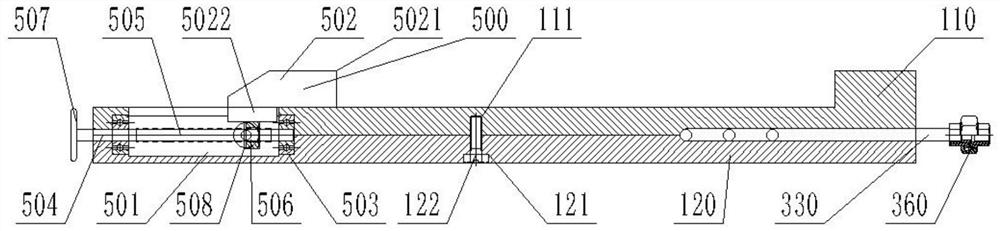

[0029] see Figure 1-7 , an auxiliary tooling for grinding machine processing, including a base 100 and a horizontal clamping device 500;

[0030] The bottom of the base 100 is flat and is made of stainless steel, so that the whole work can be fixed on the magnetic table of the grinder by means of magnetic suction;

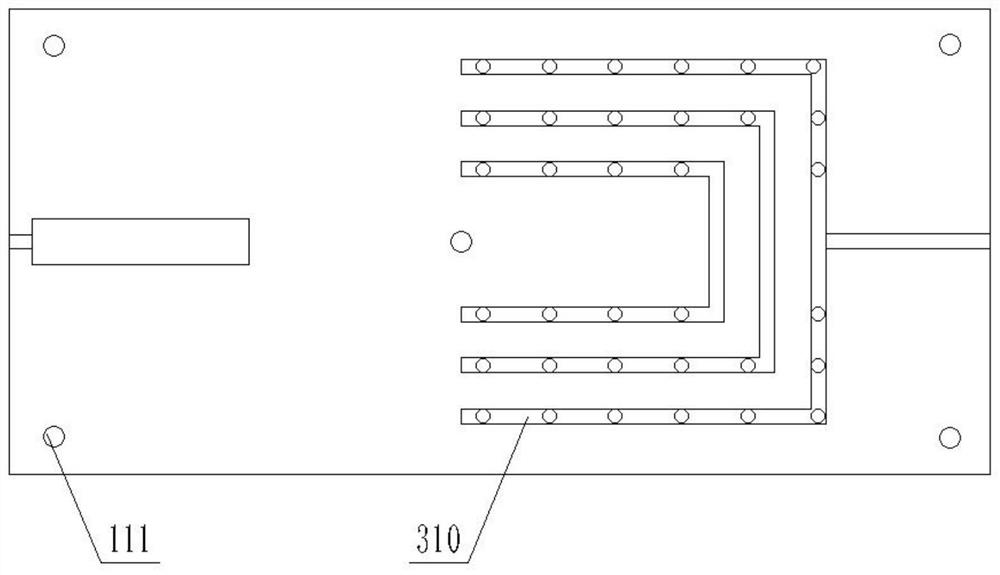

[0031] The top of the base 100 is provided with a fixing groove 200, and a plurality of annular vacuuming grooves 300 are arranged in the fixing groove 200. The overall vacuumizing groove 300 is in a concave shape, and the cross section of the vacuumizing groove 300 is circular;

[0032] And the several vacuumizing grooves 300 are connected with each other, the top of the vacuumizing grooves 300 is provided with a number of branch holes 301, and the vacuumizing grooves 300 are connected with air holes 400,

[0033] When in use, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com