Sintered aluminum electrolytic capacitor ultrahigh-voltage anode foil and preparation method thereof

A technology for aluminum electrolytic capacitors and anode foils, applied in electrolytic capacitors, capacitors, circuits, etc., can solve problems such as the difficulty in increasing the surface area of corroded foils, achieve high capacity, save raw materials, and reduce the generation of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A method for preparing an ultra-high voltage anode foil of a sintered aluminum electrolytic capacitor of the present invention comprises the following steps:

[0046]1) Mix spherical high-purity aluminum powder with a particle size of 0.5-20 μm with solvent and binder to prepare aluminum powder slurry.

[0047] The preparation of aluminum powder slurry requires the use of one or more of water, glycerol, ethylene glycol, terpineol, ketones, and castor oil as solvents, and the use of carboxycellulose, sodium alginate, starch, and vinyl polymers , epoxy resin, carbon nanotubes, graphene, silicone resin, organic fluoropolymer or fluorine resin as a binder;

[0048] 2) The coating method of aluminum powder slurry can be roller coating, spray coating or screen printing. Finally, carry out vacuum drying at 50-150°C to remove the organic or inorganic solvent components in the slurry;

[0049] Under the formation voltage of ultra-high voltage, the grown oxide film is very thic...

Embodiment 1

[0064] 1) The spherical high-purity aluminum powder with a particle size of 0.5 μm is mixed with a solvent and a binder to make an aluminum powder slurry.

[0065] The preparation of aluminum powder slurry requires the use of water as a solvent and carboxycellulose as a binder;

[0066] 2) The coating method of aluminum powder slurry can be roller coating, spray coating or screen printing. The thickness of one side of the coating is 20 μm, and the thickness of the aluminum foil substrate is selected to be 10 μm. After coating, vacuum drying is carried out at 50 ° C. Treatment to remove the organic or inorganic solvent components in the slurry;

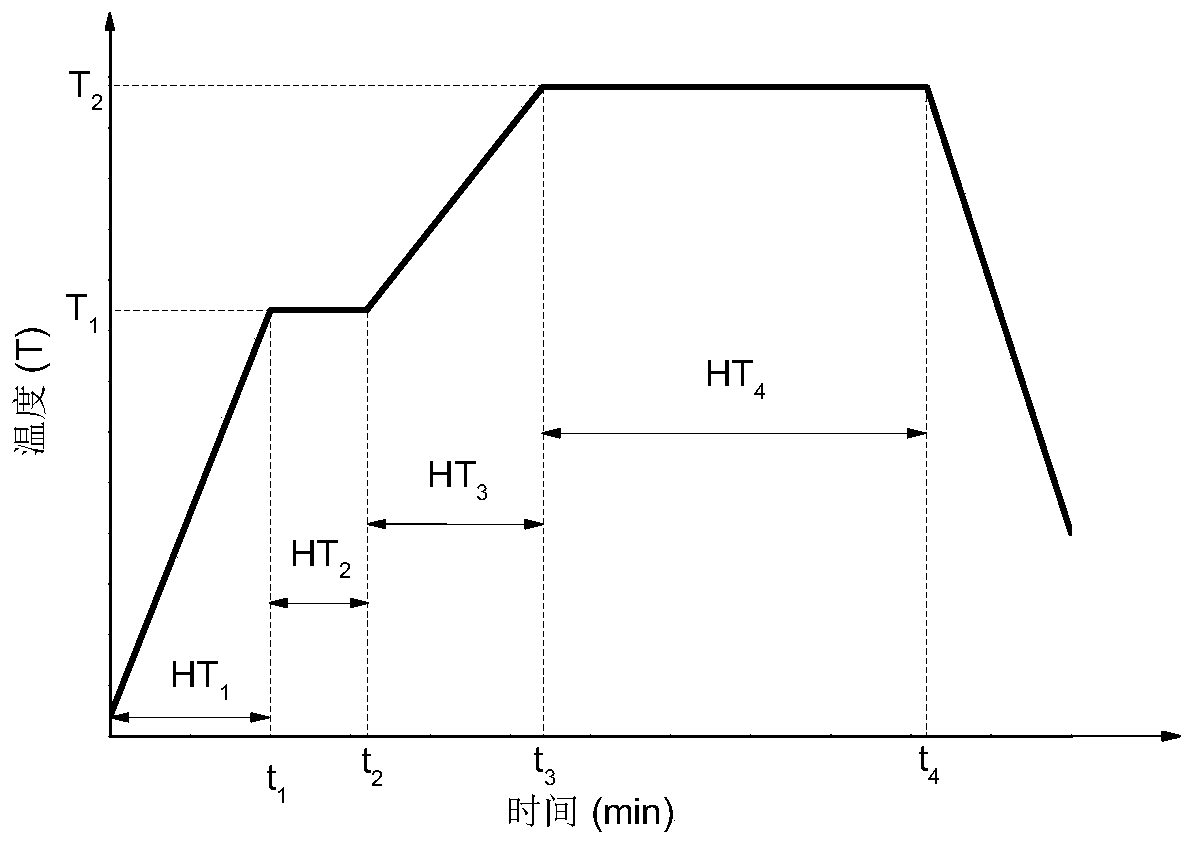

[0067] 3) the aluminum foil coated in the previous step according to figure 1 The program set in the sintering process, such as figure 1 shown in;

[0068] First at HT 1 During the process, the aluminum foil is raised from room temperature to 300°C at a rate of 1°C / min. At this time, the temperature is T1, and 1h of HT is carried o...

Embodiment 2

[0079] A method for preparing an ultra-high voltage anode foil of a sintered aluminum electrolytic capacitor of the present invention comprises the following steps:

[0080] 1) The spherical high-purity aluminum powder with a particle size of 5 μm is mixed with a solvent and a binder to make an aluminum powder slurry.

[0081] To prepare aluminum powder slurry, glycerin and ethylene glycol are used as solvents, and carboxycellulose and sodium alginate are used as binders;

[0082] 2) The coating method of aluminum powder slurry can be roller coating, spray coating or screen printing, etc. The thickness of one side of the coating is 40 μm, and the thickness of the aluminum foil substrate is selected to be 15 μm, and vacuum drying is carried out at 80 ° C after coating Treatment to remove the organic or inorganic solvent components in the slurry;

[0083] 3) the aluminum foil coated in the previous step according to figure 1 The program set in the sintering process, such as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com