Fluoroplastic cable and production process thereof

A production process, fluoroplastic technology, applied in insulated cables, cable/conductor manufacturing, plastic/resin/wax insulators, etc., can solve the problems of building collapse, face high temperature, extremely high cable requirements, etc., and achieve good stability , the effect of long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

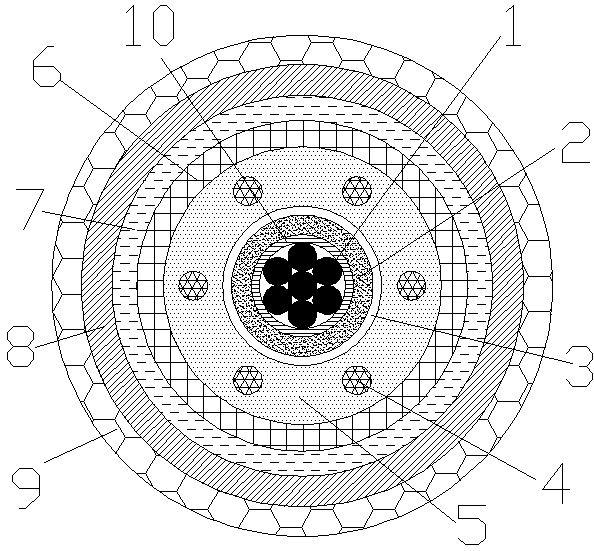

[0030] figure 1 Among them, a fluorine plastic cable, in the figure: 1. Conductor A, 2. Non-Newtonian fluid, 3. Rubber hose, 4. Conductor B, 5. Glass fiber layer, 6. Graphite fiber layer, 7. Kevlar fiber layer , 8. Polyurethane sheath layer, 9. Aluminum tape armor layer, 10. High temperature vulcanized silicone rubber layer. It includes a cable core, which is characterized in that: the cable core is formed by twisting several wires A, the structure of the wire A is, the innermost layer is a silver-plated single crystal copper core, and the silver-plated single crystal copper core is peripheral There is a polytetrafluoroethylene insulating layer A, and a basalt fiber layer is arranged outside the polytetrafluoroethylene insulating layer A, and a copper wire braiding layer is arranged outside the basalt fiber layer; a high-temperature vulcanized silicon rubber layer is arranged outside the cable core , the high-temperature vulcanized silicone rubber layer is provided with a rub...

example 2

[0044] A fluoroplastic cable, comprising a cable core, the cable core is formed by twisting several conductors A, the structure of the conductors A is that the innermost layer is a silver-plated single-crystal copper core, and the silver-plated single-crystal copper core is There is a polytetrafluoroethylene insulating layer A outside, and a basalt fiber layer is arranged outside the polytetrafluoroethylene insulating layer A, and a copper wire braiding layer is arranged outside the basalt fiber layer; a high-temperature silicon sulfide is arranged outside the cable core. A rubber layer, the high-temperature vulcanized silicone rubber layer is provided with a rubber tube, the material of the rubber tube is also high-temperature vulcanized silicone rubber, a non-Newtonian fluid is provided between the high-temperature vulcanized silicone rubber layer and the rubber tube, and a glass fiber is provided outside the rubber tube Layer, the glass fiber layer is evenly distributed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com