A kind of graphene modified carbon fiber pre-fabric and preparation method thereof

A graphene modification, carbon fiber technology, applied in the direction of carbon fiber, liquid repellent fiber, fiber treatment, etc., can solve the problems affecting power stability and life, low bonding strength, easy delamination, etc., to achieve a wide range of applications Value, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

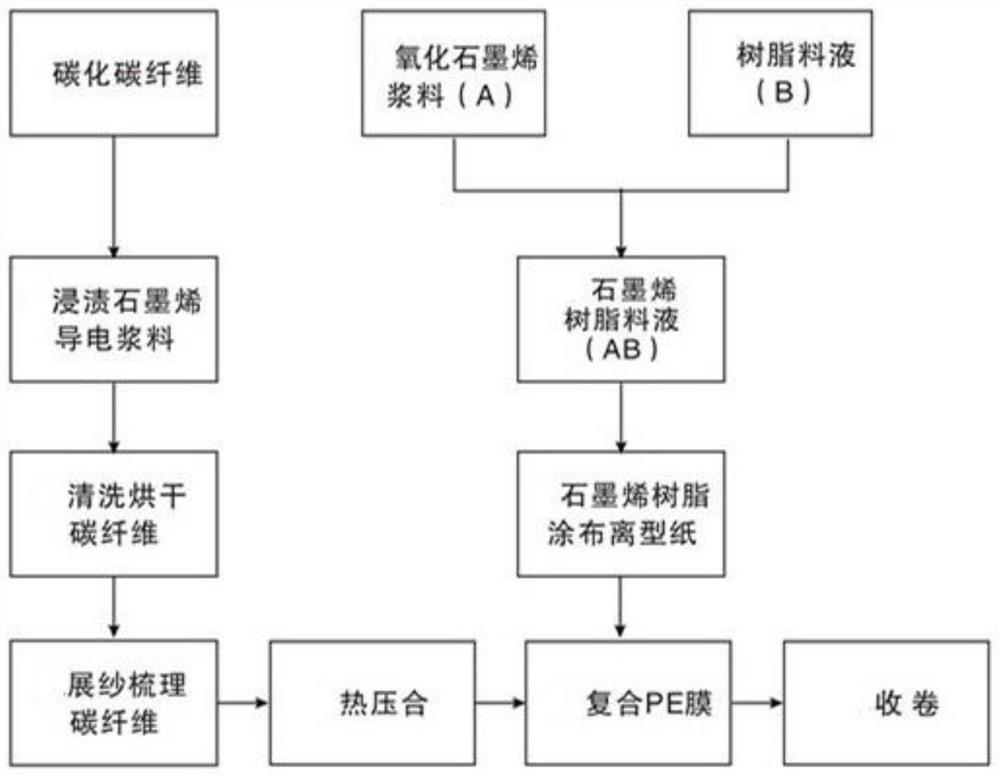

Method used

Image

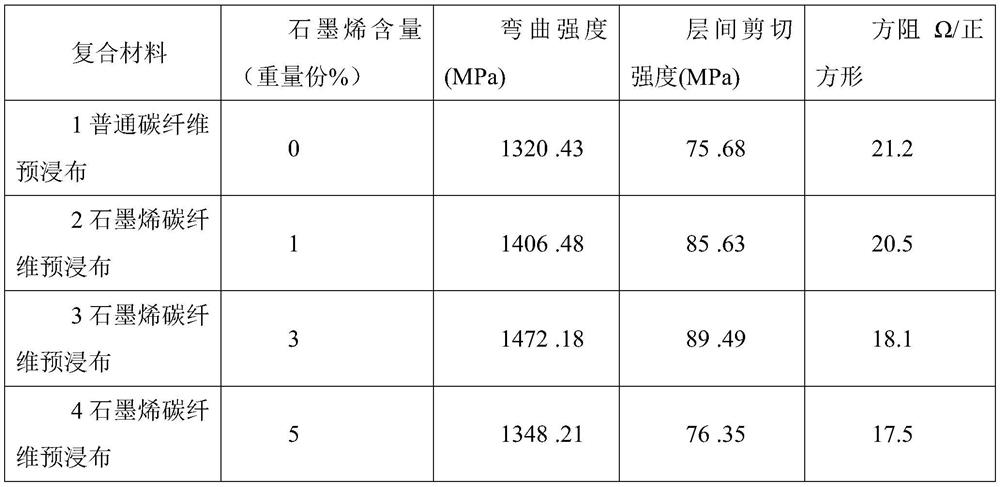

Examples

Embodiment 1

[0022] Example 1. Preparation of ordinary carbon fiber prepreg

[0023] The preparation method of common carbon fiber pre-fabrication comprises the following steps:

[0024] 1. Preparation of modified resin prepreg

[0025] (1) prepare resin acetone solution; choose 100 parts of resin, melt and stir the resin under 70 ℃ heating state for 50min to obtain resin liquid;

[0026] (2) Coating the resin liquid on the release paper with a film coater to obtain a resin composite release paper.

[0027] 2. Preparation of conductive prepreg

[0028] (1) Use a hot-pressing roller to clamp the carbon fibers in the clockwise direction between two layers of resin composite release papers in step 2, and carry out multi-pass hot rolling and yarn-spreading compounding;

[0029] (2) Peel off the upper single-sided release paper;

[0030] (3) Composite PE film, and roll up to complete ordinary carbon fiber prepreg.

Embodiment 2

[0031] Example 2. Preparation of modified carbon fiber pre-fabricated fabric

[0032] The preparation method of the graphene-modified carbon fiber prefabricated cloth of the present invention comprises the following steps:

[0033] 1. Preparation of modified carbon fiber

[0034] (1) select 1 part of graphene conductive paste of 5% concentration, and fully mix 30 parts of acetone liquid with ultrasonic mixer to obtain graphene conductive paste;

[0035] (2) Instantaneous high-temperature carbonization of carbon fiber at a temperature of 550 °C with a high-temperature electric heating tube;

[0036] (3) Continuous immersion through the graphene conductive slurry tank;

[0037] (4) Continuously soaking through the hydrogen peroxide water tank to clean and oxidize the carbon fibers;

[0038] (5) continuous drying treatment through a high-temperature electric heating tube at 200° C. to obtain graphene-modified carbon fibers.

[0039] 2. Preparation of modified resin prepreg

...

Embodiment 3

[0048] Embodiment 3; Preparation of graphene modified prepreg

[0049] The preparation method of the graphene-modified carbon fiber prefabricated cloth of the present invention comprises the following steps:

[0050] 1. Preparation of modified carbon fiber

[0051] (1) select 3 parts of graphene conductive paste of 5% concentration, and fully mix 30 parts of acetone liquid with ultrasonic mixer to obtain graphene conductive paste;

[0052] (2) Instantaneous high-temperature carbonization of carbon fiber at a temperature of 550 °C with a high-temperature electric heating tube;

[0053] (3) Continuous immersion through the graphene conductive slurry tank;

[0054] (4) Continuously soaking through the hydrogen peroxide water tank to clean and oxidize the carbon fibers;

[0055] (5) continuous drying treatment through a high-temperature electric heating tube at 200° C. to obtain graphene-modified carbon fibers.

[0056] 2. Preparation of modified resin prepreg;

[0057] (1) p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com