Flexible silicon carbide nanofiber/carbon nanofiber composite felt material and preparation method thereof

A technology of carbon nanofibers and nanofibers, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, and fabric surface trimming, etc., which can solve the problems of high production costs, decreased purity of SiC nanofibers, and high prices, and achieve easy recycling and reuse , Excellent cycle performance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Specifically, as a possible implementation mode, the preparation method of the flexible SiC nanofiber / carbon nanofiber composite felt material in the present invention includes the following steps:

[0039] (1) Preparation of precursor solution: weigh a certain mass of silicon source and add it into a polar solvent, then stir at room temperature for 4-8 hours. After fully dispersed, add a certain mass of polymer-based carbon precursor, continue to stir for 4-12 hours, and stand for defoaming before use.

[0040] (2) Precursor forming: the precursor solution obtained in step (1) is subjected to solution jet spinning, gas-electric blending or centrifugal spinning to prepare a precursor nanofiber mat.

[0041] (3) Heat treatment of precursor nanofiber felt: put the precursor nanofiber felt obtained in step (2) into a calciner for pre-oxidation treatment, and then place it in a high temperature furnace under an inert gas atmosphere to carry out high temperature carbonizatio...

Embodiment 1

[0052] S11, preparation of precursor solution: 30g of SiO 2 Nanoparticles (particle size: 7-40nm) were added into 1000ml of N,N-dimethylformamide solvent, stirred and dispersed at room temperature for 4h. After adding 140g of polyacrylonitrile (molecular weight M w =50,000), continue stirring for 12h to form a homogeneous mixed solution, which is filtered through an 800-mesh filter for subsequent use.

[0053] S12, precursor forming: pump the precursor solution in step S11 into a metering pump for solution jet spinning. The propulsion speed is 800ml / h, the hot air temperature in the tunnel is 55°C, and the air flow rate at the inlet and outlet is 1200m 3 / h, the spinneret hole diameter is 0.5mm.

[0054] S13, heat treatment of the precursor nanofiber mat: put the fibrous precursor in step S12 into a calciner at a heating rate of 5°C / min, raise the temperature to 250°C and keep it warm for 2h, and perform pre-oxidation under air conditions; Carry out carbonization treatment...

Embodiment 2

[0058] Adjust the holding time in the high-temperature carbonization step in Step S13 of Example 1 to 1 h, and the rest of the steps are the same as in Example 1 to obtain a flexible SiC nanofiber / carbon nanofiber composite felt material.

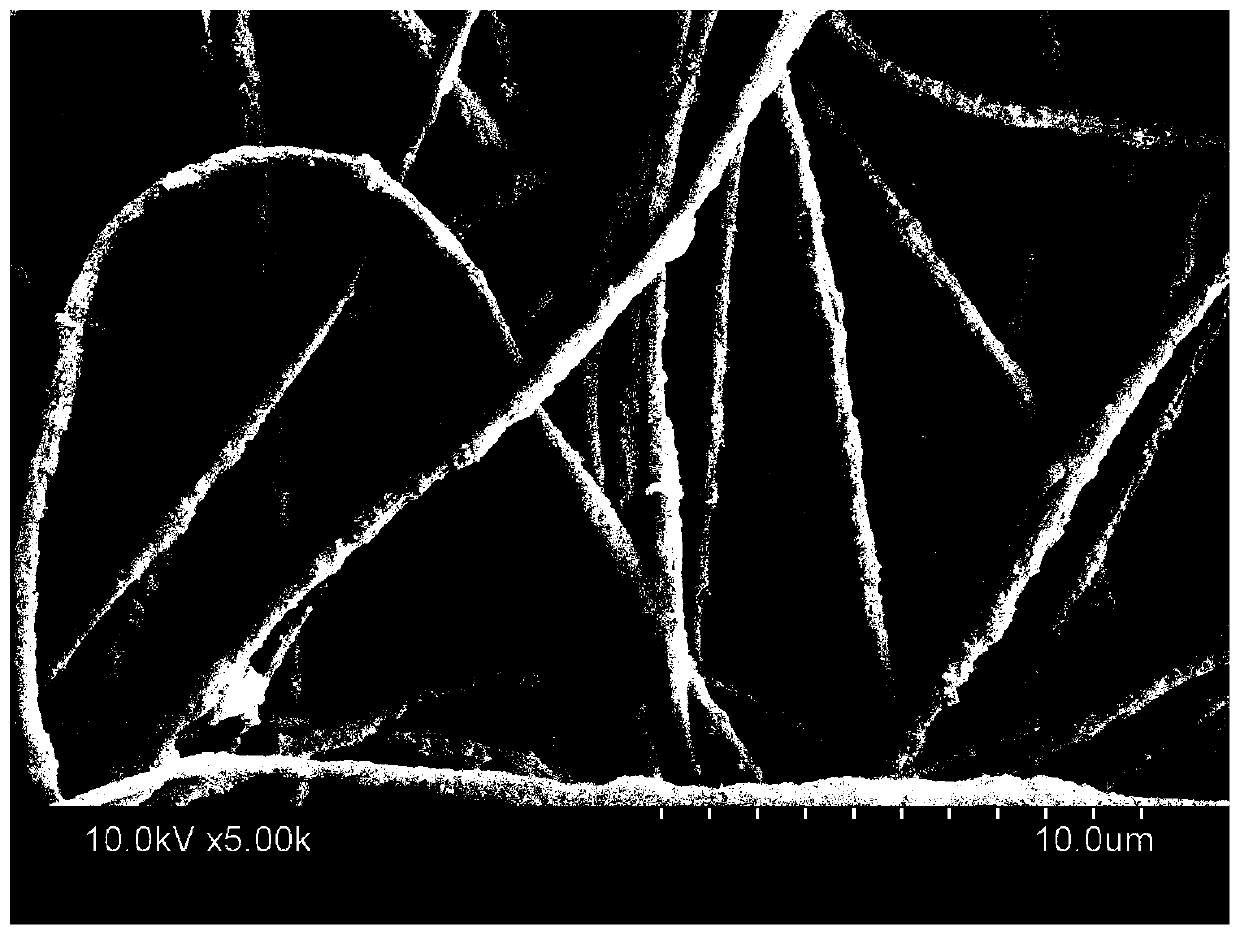

[0059] The structural performance of the nanofiber composite mat that the present embodiment makes is as follows Figure 5 As shown, the SiC nanofiber structure is in the shape of a spiral hook, and the diameter distribution is relatively uniform at 80-100 nm.

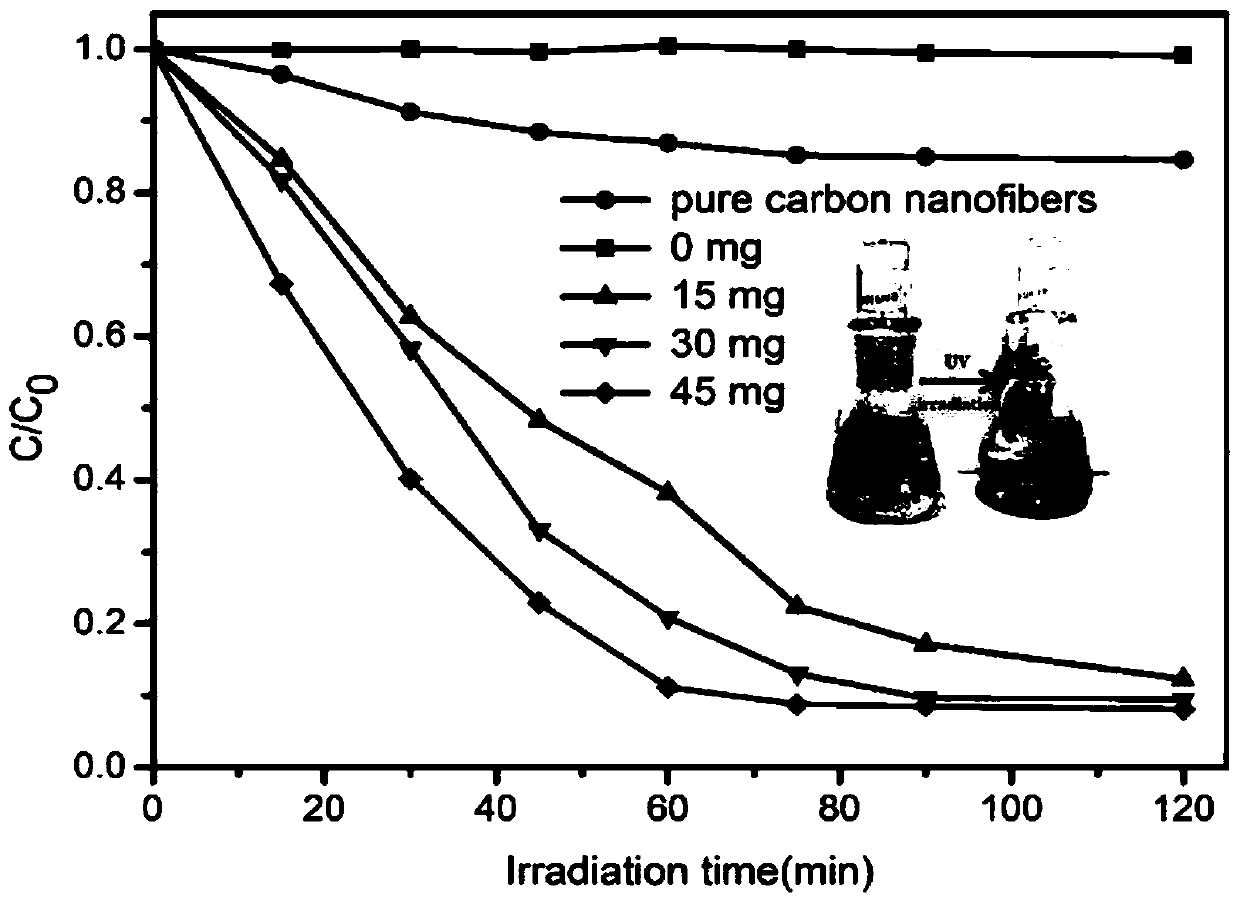

[0060] According to the experimental test, the catalytic degradation methyl orange solution of the flexible SiC nanofiber / carbon nanofiber composite felt in this example is lower than that of Example 1, the removal efficiency is about 85%, and the removal rate is about 84% after repeated use for 5 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com