A method for controlling the heating temperature of a cylindrical workpiece

A heating temperature and control method technology, applied in the field of heat treatment, can solve problems such as low accuracy of simulation results, long time consumption, and reduced production efficiency, so as to improve fuel utilization and heating efficiency, reduce production costs, and improve control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with embodiment the present invention is described in further detail:

[0050] The workpiece 3 to be heated in the present invention adopts a circular steel pipe, and the specification size is: φ200mm×2300mm, the inner diameter Required heating temperature 650℃≤T≤700℃; round steel pipe number n=5; standard effective heating rate σ e = 90%.

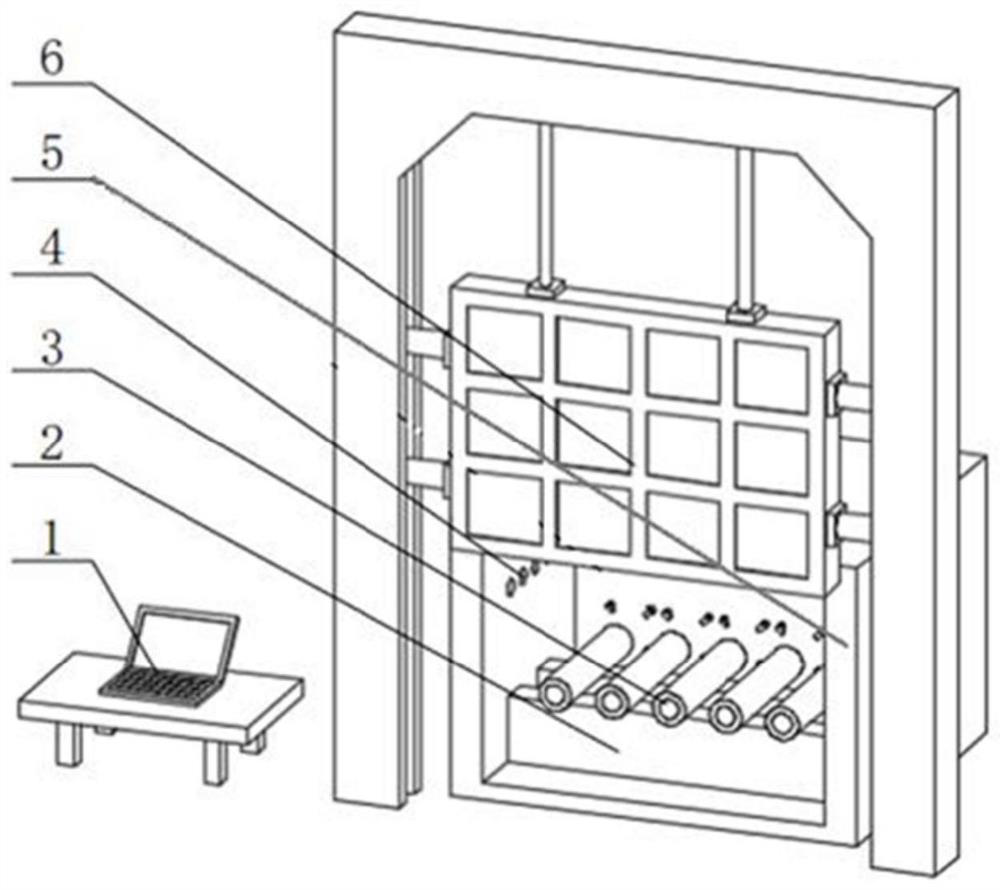

[0051] Such as figure 1 The shown schematic diagram of the heating furnace is a control device for the heating temperature of a cylindrical workpiece, including a control device body, the control device body is provided with a bracket 2 supporting a plurality of workpieces 3 to be heated, and the plurality of workpieces 3 are evenly distributed. , symmetrically distributed on both sides of the front and back in the heating furnace 6, the position where the bracket 2 is in contact with a plurality of workpieces 3 to be heated is provided with a temperature-measuring thermocouple, and the inner furnace surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com