Method for producing ethanol by semi-synchronous enzymolysis and fermentation of degreased peanut powder prehydrolysate and pretreated solid matrix

A technology of degreased peanuts and pre-hydrolyzate, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of increasing the production cost of lignocellulosic fuel ethanol, increasing the steps of pretreatment, etc., and achieve the promotion of commercial The effects of promotion and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Preparation of bamboo pretreatment solid substrate:

[0051] First, add 10g of bamboo powder that has passed through a 40-mesh sieve into a microwave reaction tank with a polytetrafluoroethylene lining, add 150g of benzenesulfonic acid in water, the mass percentage of benzenesulfonic acid in the pretreatment liquid is 80%, and seal the microwave After the reaction tank was treated at 95°C for 30 minutes, after the pretreatment was completed, the microwave reaction tank was taken out and placed in cold water to cool to room temperature, and then solid-liquid separation was carried out in a Buchner funnel lined with filter paper; then, the pretreatment was washed with deionized water Treat the solid substrate to the pH of the filtrate in the range of 6.8 to 7.0, and use the cleaned pretreated solid substrate for subsequent semi-synchronous enzymatic hydrolysis and fermentation.

[0052] (2) Pre-hydrolysis of defatted peanut flour:

[0053] First, put 20g of defatted peanut ...

Embodiment 2~6

[0073] Examples 2 to 6 and Comparative Examples 2 to 4

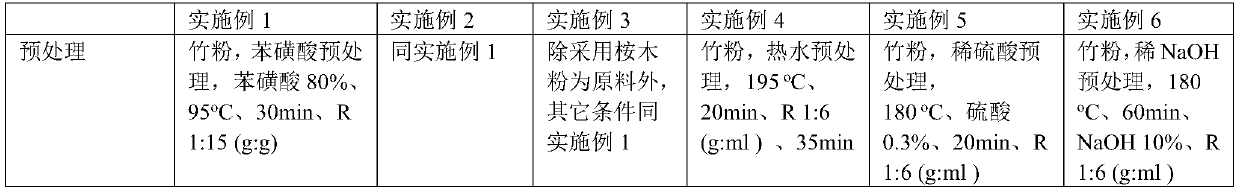

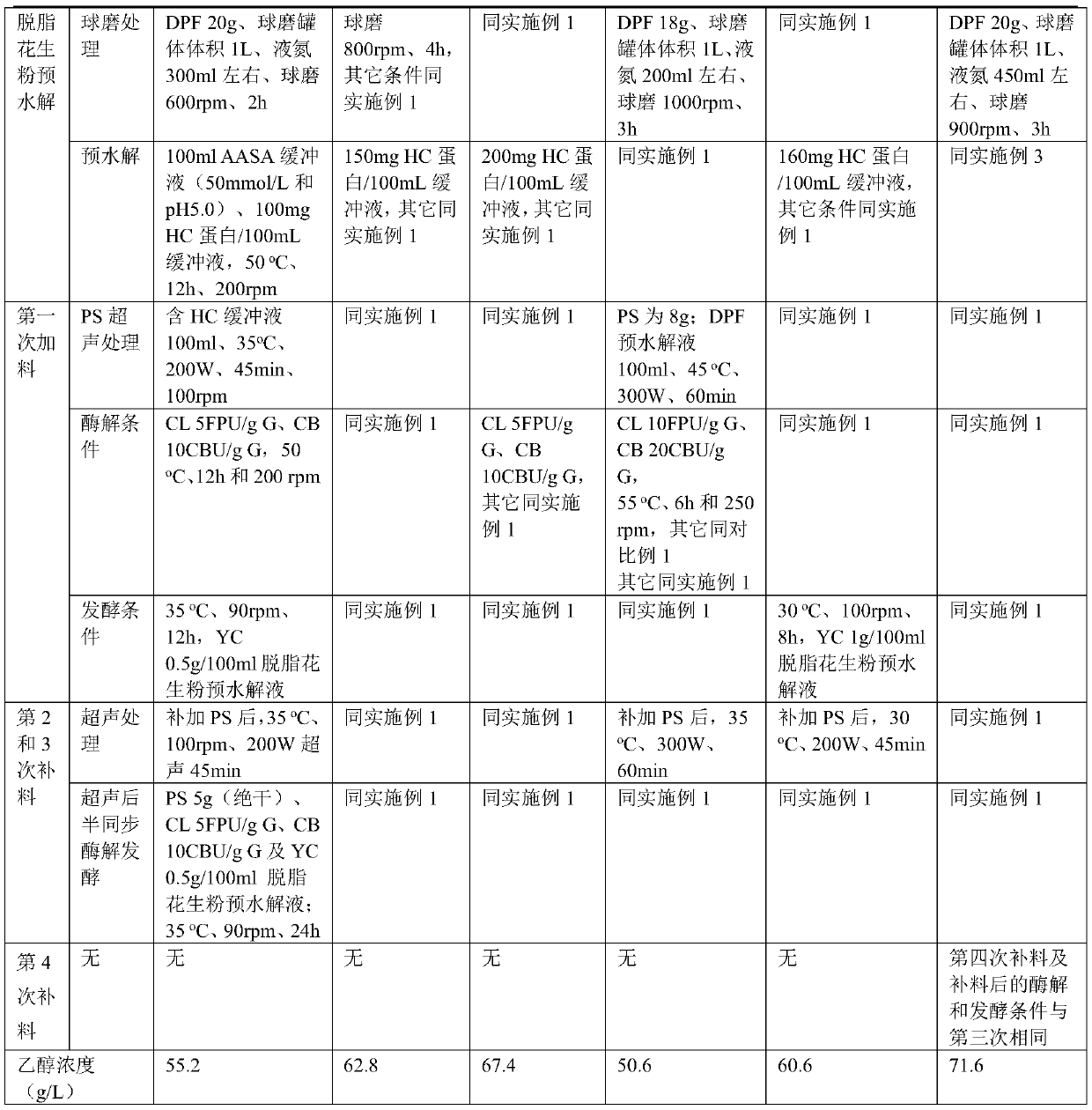

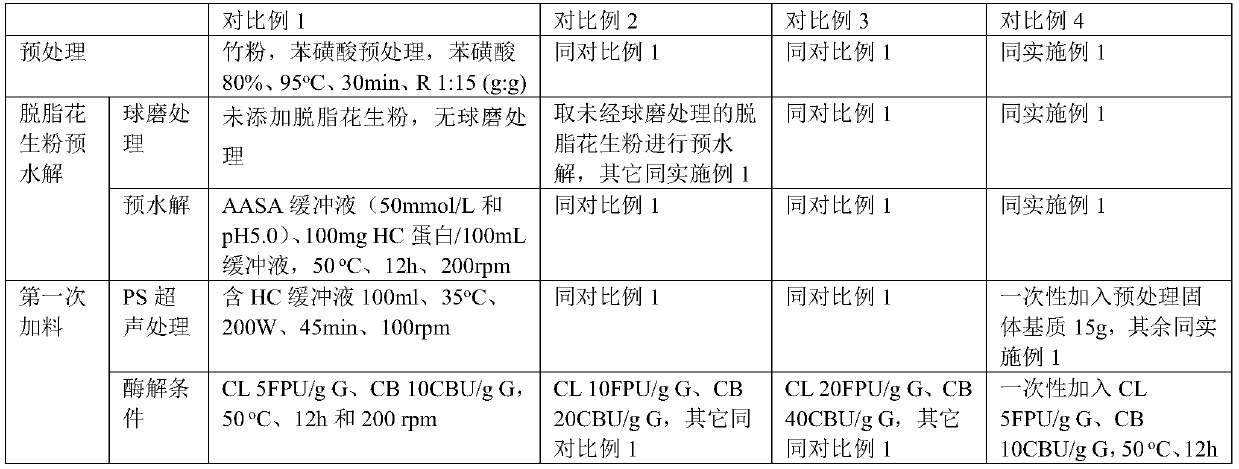

[0074] The specific schemes and ethanol fermentation results of Examples 2 to 6 and Comparative Examples 2 to 4 are shown in Table 1 and Table 2, respectively:

[0075] Woody biomass raw materials are all 40 mesh bamboo powder or eucalyptus powder; HC, CL, CB, G and YC are the abbreviations for hemicellulase, cellulase, cellobiase, glucan and yeast cells, respectively; R is the abbreviation of pretreatment solid-liquid ratio; AASA is the abbreviation of acetic acid-sodium acetate; DPF is the abbreviation of defatted peanut powder; PS is the abbreviation of pretreatment solid substrate.

[0076] For the pretreatment of benzenesulfonic acid, hot water, dilute sulfuric acid or dilute NaOH, after the pretreatment is completed, use a Buchner funnel with filter paper for solid-liquid separation, and wash the pretreated solid substrate with deionized water until the filtrate pH is 6.8 In the range of ~7.0, the washed pretreated solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com