Method for preparing composite passivator for soil heavy metals from kitchen waste

A technology of kitchen waste and passivation agent, which is applied in chemical instruments and methods, restoration of polluted soil, soil conditioning materials, etc., can solve problems such as difficult targets, negative impact on soil environment, and difficulty of passivation agent materials, etc. Achieve the effect of low production cost, good passivation effect and good passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

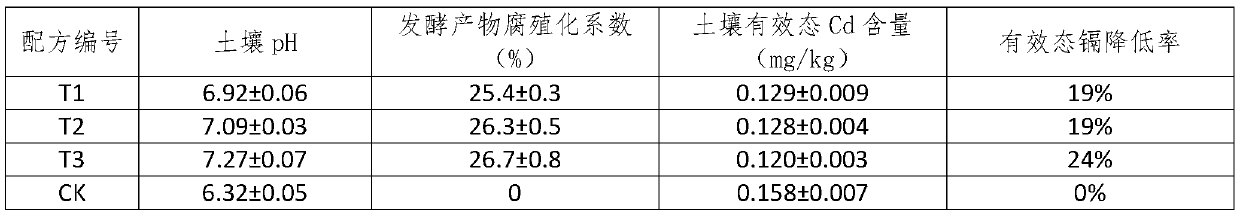

[0034] Take low-fat food waste and lignite powder in a ratio of 1:1 and ferment according to the above-mentioned preparation method, and then configure T1 with calcium oxide and calcium-based bentonite respectively according to the following mass ratio (fermentation product: calcium oxide: calcium-based bentonite = 20:35:45), T2 (fermentation product: calcium oxide: calcium-based bentonite = 35:30:35), T3 (fermentation product: calcium oxide: calcium-based bentonite = 30:45:25), according to 1.60g / kg The application and cadmium-contaminated soil, in which CK is no passivation agent, the results of the reduction rate of soil effective cadmium content obtained by the application of different passivation agent formulations are shown in Table 1.

[0035] Table 1 Effects of different ratios of passivators on soil available cadmium content

[0036]

[0037] It can be seen from the above table that the formula T3 has a reduction rate of 24% for the effective content of cadmium in ...

Embodiment 2

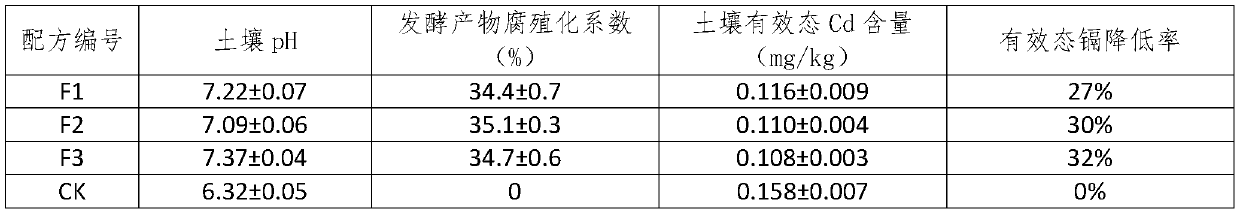

[0039] Take low-fat food waste and lignite powder in a ratio of 1:1.25 and ferment according to the above-mentioned preparation method, and then configure F1 with calcium oxide and calcium-based bentonite respectively according to the following mass ratio (fermentation product: calcium oxide: calcium-based bentonite = 20:35:45), F2 (fermentation product: calcium oxide: calcium-based bentonite = 35:30:35), F3 (fermentation product: calcium oxide: calcium-based bentonite = 30:45:25), according to 1.60g / kg The application and cadmium-contaminated soil, in which CK is no passivation agent, the results of the reduction rate of soil effective cadmium content obtained by the application of different passivation agent formulations are shown in Table 2.

[0040] Table 2 Effects of different ratios of passivators on soil available cadmium content

[0041]

[0042] It can be seen from the above table that the formula F3 has a reduction rate of 32% for the effective content of cadmium ...

Embodiment 3

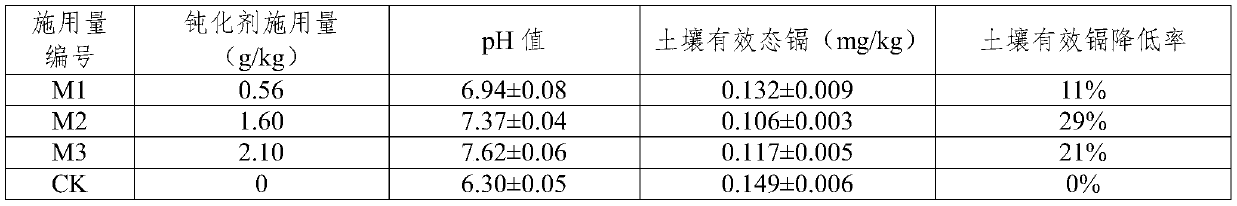

[0044] Take low-fat food waste and lignite powder in a ratio of 1:1.25 and ferment according to the above preparation method, then mix with calcium oxide and calcium-based bentonite according to the following mass ratio of 30:45:20, and apply 0g / kg to the target soil respectively , 0.56g / kg, 1.60g / kg, 2.10g / kg, the results of different application rates on the reduction rate of soil available cadmium content are shown in Table 3.

[0045] Table 3 Effects of different passivating agent application rates on soil available cadmium content

[0046]

[0047]It can be seen from the above table that when the application rate of the passivator is 1.60g / kg, a good effect is obtained, and the content of available cadmium in the soil is reduced by 29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com