Preparation method of titanium dioxide pigment with high electrical resistivity

A technology of titanium dioxide and high resistivity, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of coating swelling, good conductivity, alkali, etc., to reduce adsorption and increase resistivity , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

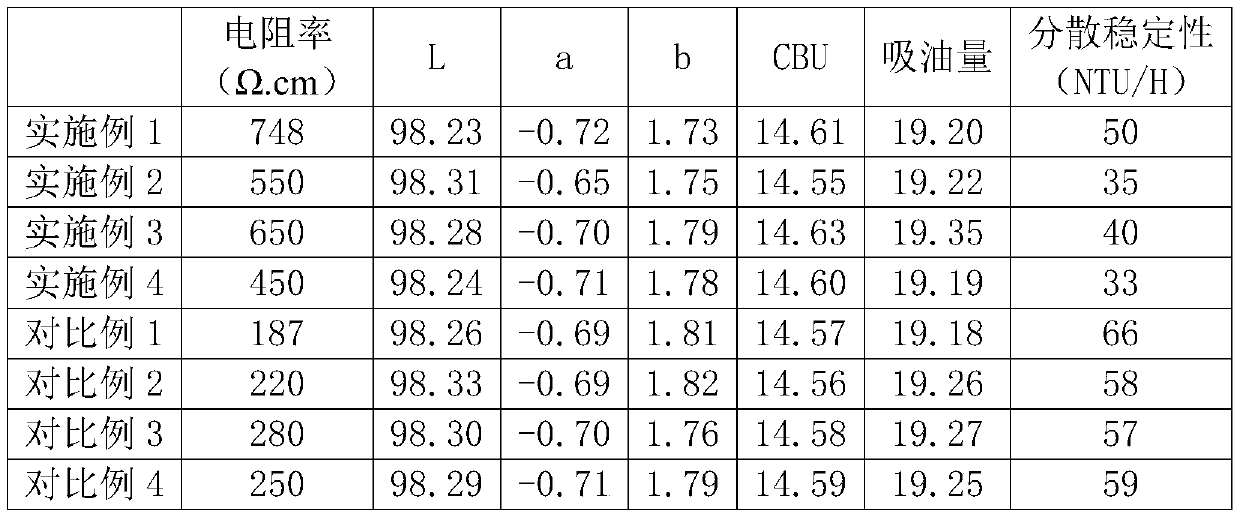

Examples

Embodiment 1

[0023] The rutile titanium dioxide semi-finished product prepared by the chlorination method was beaten with deionized water to obtain a titanium dioxide slurry with a mass concentration of 25%, stirred for 20 minutes, and a sodium hydroxide solution with a mass concentration of 25% was added to adjust the slurry to pH5.0. , stirring for 10min; adding propylene glycol methyl ether acetate as a wetting agent, its addition accounted for 2 0.1% by mass, stirred for 10 minutes, adjusted the slurry to pH 9.0, stirred for 10 minutes; added silicate, citric acid and ethylenediamine water-soluble salt solution as a dispersant, wherein sodium silicate, citric acid, ethyl The mass ratio of diamine to water is 15:15:10:65, and the amount added accounts for 2 0.3% by mass, stir for 20 minutes, continue to adjust the pH value of the slurry to 9.0 with a sodium hydroxide solution with a mass concentration of 25%, stir for 5 minutes, raise the temperature of the slurry to 70°C, add sodium me...

Embodiment 2

[0025] The rutile-type titanium dioxide semi-finished product prepared by the chlorination method was beaten with deionized water to obtain a titanium dioxide slurry with a mass concentration of 35%, stirred for 40 minutes, and a sodium hydroxide solution with a mass concentration of 35% was added to adjust the slurry to pH 5.5. Stir for 10min; add propylene glycol methyl ether acetate as wetting agent, its addition accounts for TiO 2 1% by mass, stir for 20 minutes, add 35% sodium hydroxide solution, adjust the slurry to pH 10.5, and stir for 20 minutes; add silicate, citric acid and ethylenediamine water-soluble salt solution as a dispersant, wherein , the mass ratio of sodium silicate, citric acid, ethylenediamine to water is 15:10:15:60, and the amount of dispersant added accounts for 2 0.6% by mass, stir for 40 minutes, continue to adjust the pH value of the slurry to 10.5 with a sodium hydroxide solution with a mass concentration of 35%, stir for 10 minutes, raise the te...

Embodiment 3

[0027] The rutile-type titanium dioxide semi-finished product prepared by the chlorination method was beaten with deionized water to obtain a titanium dioxide slurry with a mass concentration of 30%, stirred for 30 minutes, and a sodium hydroxide solution with a mass concentration of 30% was added to adjust the slurry to pH 5.3. Stir for 10min; add propylene glycol methyl ether acetate as wetting agent, its addition accounts for TiO 2 0.5% by mass, stirring for 15 minutes, adding 30% sodium hydroxide solution, adjusting the slurry to pH9.8, stirring for 15 minutes; adding silicate, citric acid and ethylenediamine water-soluble salt solution as a dispersant, wherein , the mass ratio of sodium silicate, citric acid, ethylenediamine to water is 15:12:12:61, and the amount of dispersant added accounts for 2 0.4% by mass, stir for 30 minutes, continue to adjust the pH value of the slurry to 10.0 with a sodium hydroxide solution with a mass concentration of 30%, stir for 8 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com