Methyl methacrylate synthesis process

A technology of methyl methacrylate and methyl acrylate, applied in the field of methyl methacrylate synthesis technology, can solve the problems of reduced economic benefit, difficult product separation, unavoidable product loss, etc., and achieves reduced separation difficulty and low purification difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

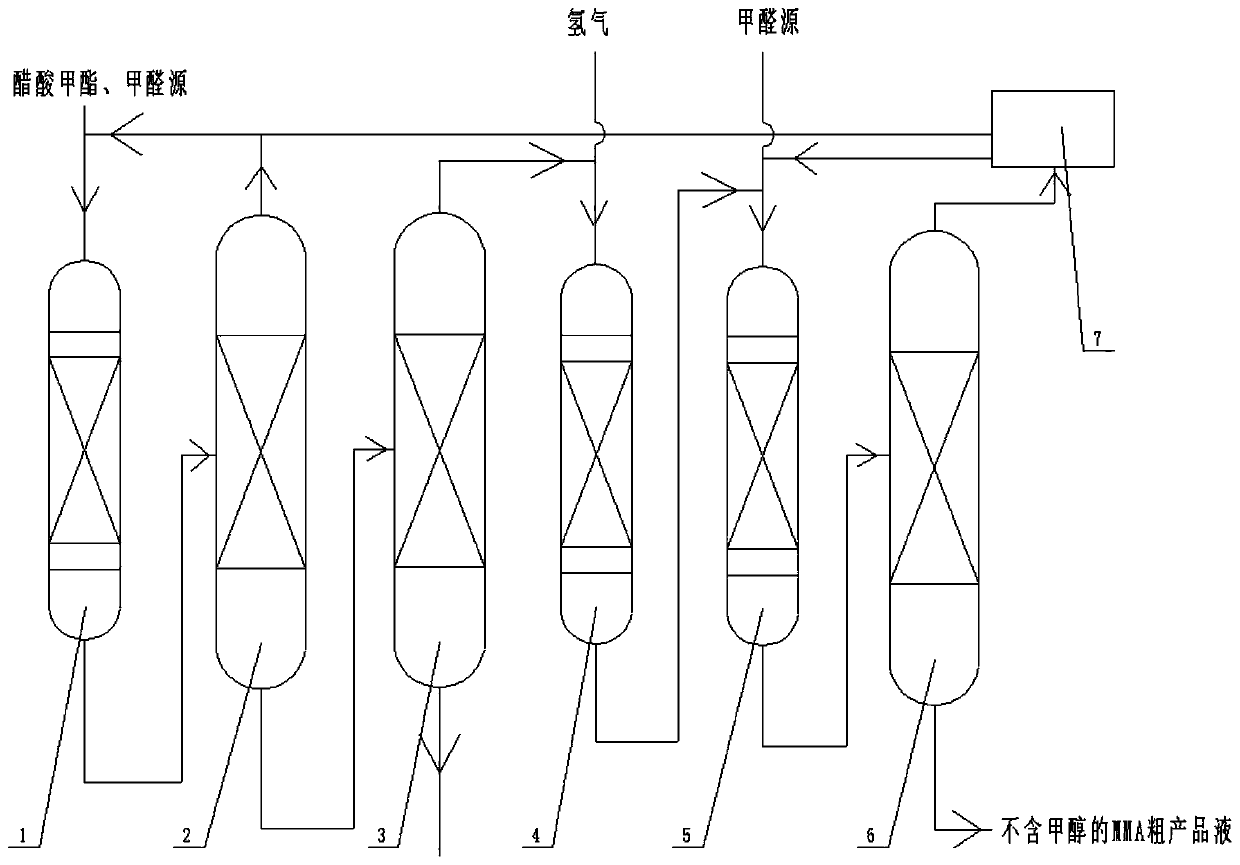

[0027] Such as figure 1 shown, including the following steps:

[0028] S1, methyl acetate, formaldehyde, returned methyl acetate and methanol mixture, returned methanol and / or carrier gas enter the first condensation reactor 1 after preheating; methyl acetate and formaldehyde undergo hydroxylation under the action of a condensation catalyst The aldehyde condensation reaction generates a gaseous product stream, which contains methyl acrylate, residual formaldehyde, residual methyl acetate and methyl alcohol introduced to suppress side reactions; the gaseous product stream of the first condensation reactor 1 is cooled and separated from gas and liquid, The liquid phase product contains more than 90% methyl acrylate, residual formaldehyde, residual methyl acetate and methanol in the gaseous product stream;

[0029] S2, the liquid phase product of step (1) gained is sent to the first separation tower 2, methyl acetate and methanol mixture are separated as light components by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com