Intelligent drilling rod compensation-type electric joint

An electric joint and compensation technology, applied in the direction of drill pipe, conductive connection, circuit, etc., can solve the problem of increasing the service life and sealing performance of the drill pipe electric joint, affecting the life and sealing performance of the drill pipe electric joint, and contact pressure on the contact surface and other problems, to achieve the effects of easy replacement, prevention of contact short circuit, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

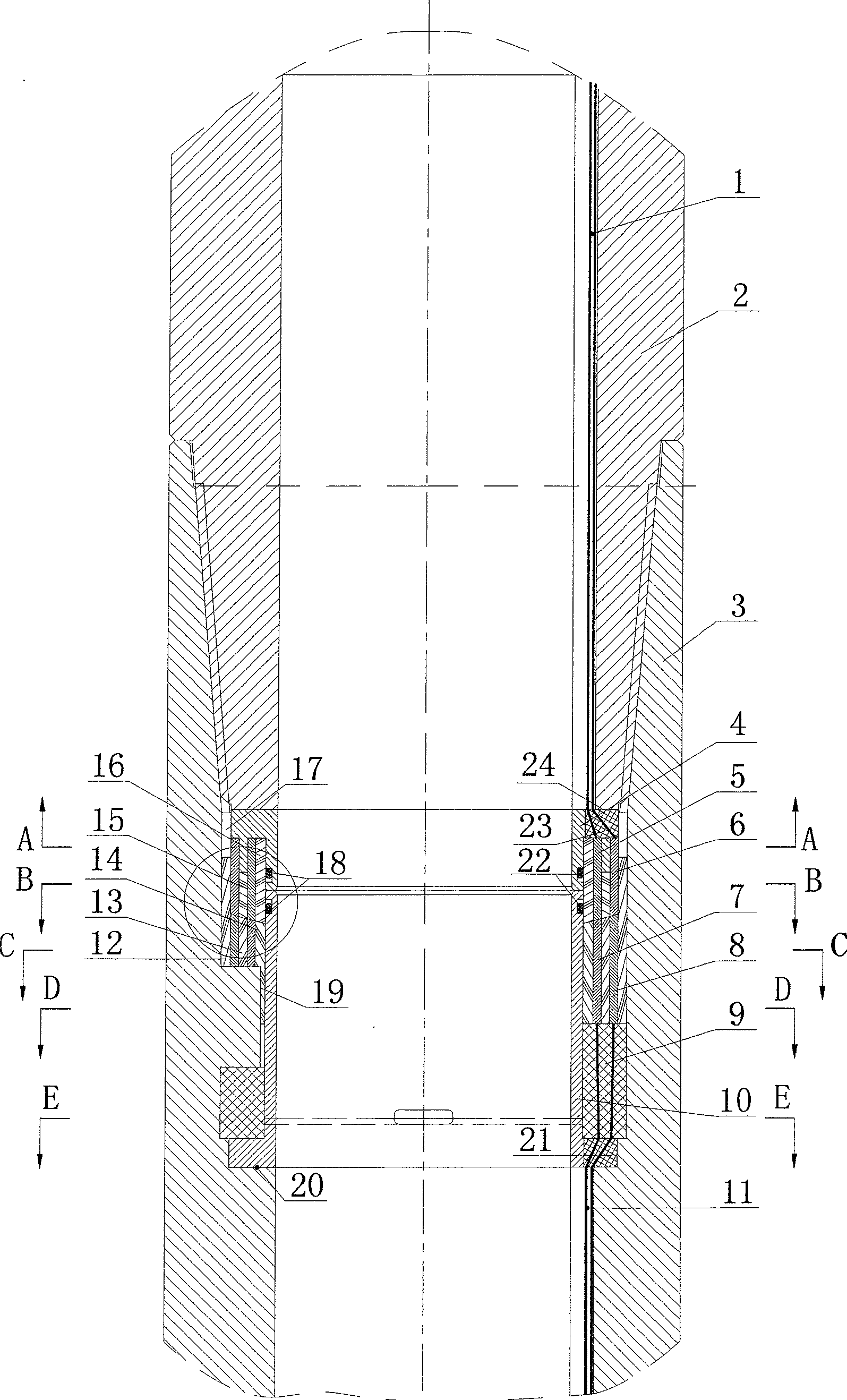

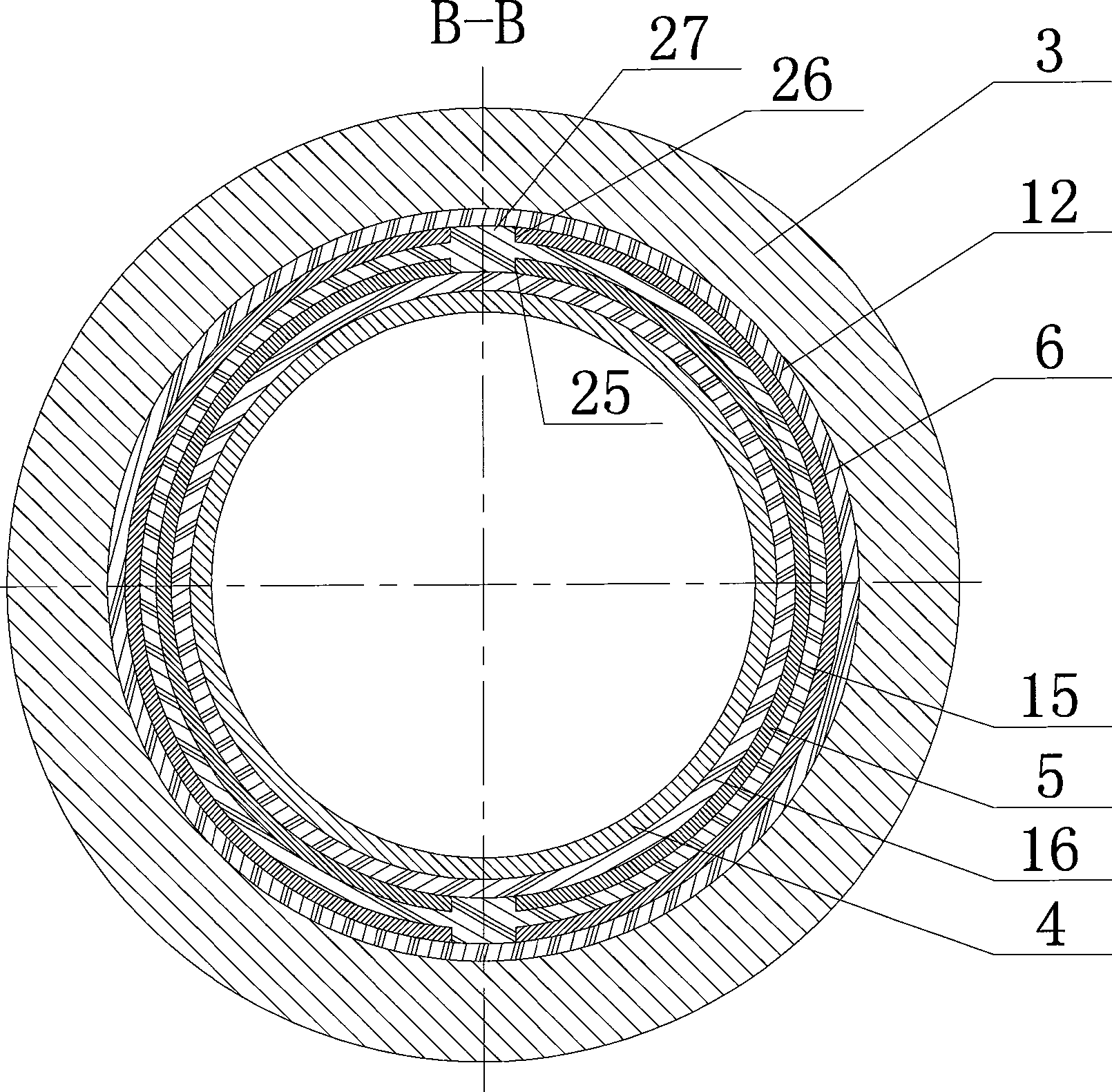

[0029] exist figure 1 Zhongzhi intelligent drill pipe compensation type electrical joint is mainly composed of two parts, namely the male electrical joint and the female electrical joint. Assembling the male inner insulating seal ring 16, the male inner conductive ring 5, the male outer insulating seal ring 15, the male outer conductive ring 6 and the male wire sealing block 23 on the metal retaining ring 4 of the male electrical connector in sequence to form the male electrical connector, and then Bond the entire male electrical joint to the end 24 of the male joint of the drill pipe, and connect it to the inner wall wire 1 of the male joint 2 of the drill pipe; bond the insulating elastic body 9 and the sealing block 21 of the female wire to the metal retaining ring 10 of the female electrical joint , and then sequentially bond the female inner insulating seal ring 14, the female inner conductive ring 7, the female outer insulating sealing ring 13, and the female outer condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com