A method for simultaneously preparing nano-calcium carbonate and chlorine-free calcium silicate early-strength agent with marble polishing slag

A nano-calcium carbonate, polishing waste residue technology, applied in chemical instruments and methods, calcium carbonate/strontium/barium, nanotechnology for materials and surface science, etc., can solve the adverse effects of human living environment, waste of recyclable resources, Occupying land resources and other issues, to achieve the effect of easy control of the reaction process, cost saving and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

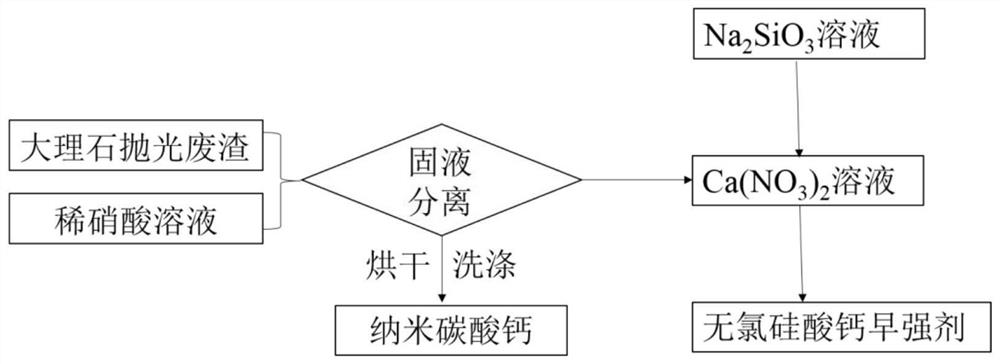

[0037] Example 1: see attached figure 1 .

[0038] A method for preparing nano-calcium carbonate and chlorine-free calcium silicate early strength agent simultaneously from marble polishing waste residue, the method comprises the following steps:

[0039] a. Preparation of nano calcium carbonate;

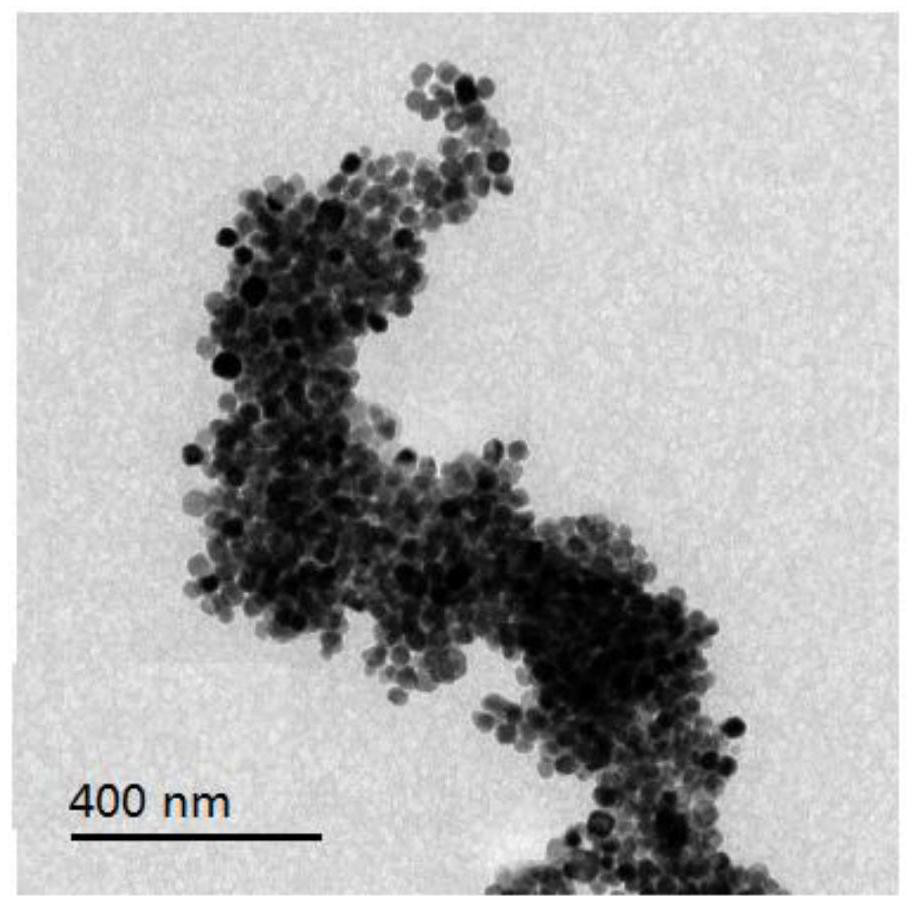

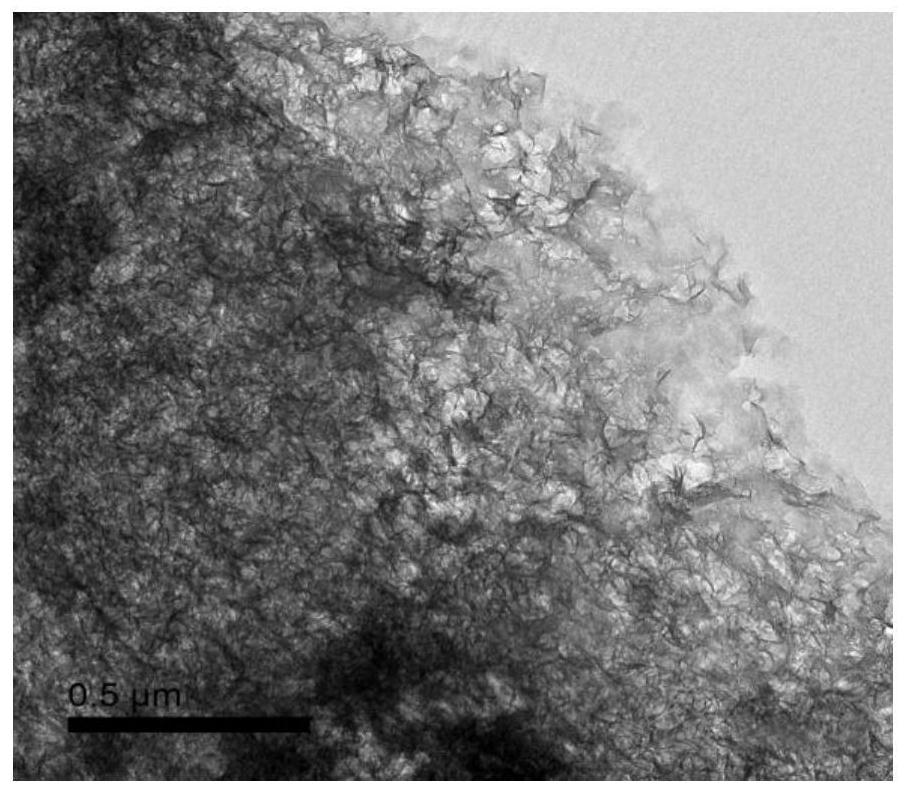

[0040] Take the marble polishing waste (particle size is D 50 = 5.4 μm) as a solid raw material, a concentration of 1.0 mol / L dilute nitric acid aqueous solution as a liquid raw material, according to the solid-liquid ratio of solid raw material: liquid raw material is 1:10 The solid raw material and the liquid raw material are mixed in the reactor, at 50 ° C After stirring the reaction time at the temperature for 3 hours, filter the reacted material (for solid-liquid separation), and then wash the solid obtained after filtration with water 4 times and dry (the solid is placed in an oven with a temperature of 50 ° C for 5 hours) , namely make nano-calcium carbonate (or be called ...

Embodiment 2

[0054] A method for preparing nano-calcium carbonate and chlorine-free calcium silicate early strength agent simultaneously from marble polishing waste residue, the concentration of the nitric acid aqueous solution reacted with marble polishing waste residue is 1.2mol / L, and the others are the same as in Example 1, and are omitted.

Embodiment 3

[0056] A method for simultaneously preparing nano-calcium carbonate and chlorine-free calcium silicate early strength agent from marble polishing waste residue. The temperature when the marble polishing waste residue reacts with the aqueous nitric acid solution is 60° C., and the rest are the same as in Example 1, and are omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com