A multi-component degradable magnesium alloy material and its preparation method and application

A magnesium alloy, multi-component technology, applied in the field of degradable magnesium alloy materials and its preparation, to achieve the effects of avoiding local failure, promoting bone growth, and promoting antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A degradable magnesium alloy material composed of multiple components, which is used to prepare cortical bone screws with multiple components (such as figure 2 As shown), according to actual needs, the bone screw body is wrapped inside the bone tissue, the strength of the screw thread needs to be increased, the toughness of the screw body must be improved, and the stress corrosion resistance must be improved, and it can also release the growth-promoting bone tissue Elements; because the nail head is in contact with soft tissue, under the premise of ensuring the required strength of the material, it is necessary to improve the corrosion resistance; in order to have a better fixing effect, it should also have a certain antibacterial ability. Therefore, the determined element requirements are: Mg, Zn, Zr, Cu, Mn, Sr, Y; according to the screw preparation sequence, the material is selectively supplied, and the alloy composition at the nail head is Mg-2Y-Zn-0.3Cu alloy. The...

Embodiment 2

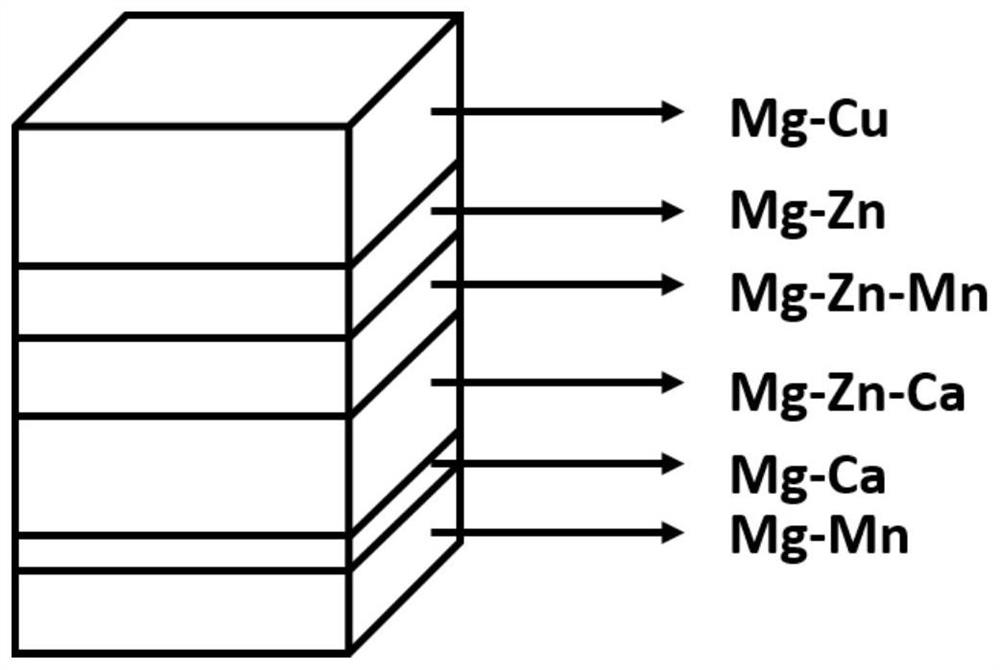

[0035] A multi-component degradable magnesium alloy material, which is used to prepare a multi-component porous bone repair material (such as image 3 As shown), according to the actual needs, the degradable porous magnesium filling material is wrapped inside the tissue. Since the edge of the porous magnesium is the first and the longest to contact body fluids, the corrosion resistance of the edge of the material should be improved, and the inner part is the main mechanical property. The load-bearing part, so the internal structure should properly improve the mechanical properties, so that the tissue can grow smoothly and evenly degrade in the end. Therefore, the element requirements are determined as: Mg, Zn, Zr, Mn, Sr; according to the preparation sequence of the porous bone repair material, Selective feeding, the composition of the edge of the porous bone repair material is Mg-2Zn-0.5Sr alloy, a small amount of Sr element can be added to promote the growth of bone cells; th...

Embodiment 3

[0041] A degradable magnesium alloy material composed of multiple components, which is used to prepare skin staples with multiple components (such as Figure 4As shown), according to actual needs, skin staples need to have higher hardness and strength at the nail tip and higher strength and toughness at the nail leg. Better corrosion resistance is required; because the nail beam has to bear the force of the stapler hitting the nailed tissue, the strength needs to be increased, but the corrosion resistance is not high, so the determined element requirements are: Mg, Al, Zn, Zr, Mn, Nd; According to the order of staple preparation, the materials are selectively supplied. The alloy composition at the nail tip is Mg-2Zn-Nd-0.5Zr; the nail leg stem is Mg-2Zn-0.3Mn alloy, and the nail leg The joint and nail beam are Mg-3Al-Zn-0.5Nd alloy.

[0042] Its preparation method is as follows:

[0043] 1) Powder preparation: place the Mg, Al, Zn, Zr, Mn, and Nd powders required in the magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com