A kind of method for preparing carbon-nitrogen airgel material based on alkali-thermal method

A gel material and nitrogen technology, applied in the field of nanomaterials, can solve the problems of complex preparation process of polymer crosslinking agent and increase the cost of use, and achieve the effect of promoting the surface chemical reaction rate, being easy to repeat, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the oxygen-doped carbon nitride aerogel photocatalyst proposed in the present invention, comprising the following steps:

[0034] (1) Bulk phase carbon nitride, hereinafter referred to as the preparation of BCN: dicyanamide and thiourea are mixed uniformly according to the mass ratio of (8 ~ 1): 1, and calcined in a muffle furnace. The heating procedure is 30 °C to 300 °C heating rate of 1 ~ 12 °C / min, 300 °C to 500 °C heating rate of 1 ~ 5 °C / min, 500 °C to 550 °C heating rate of 1 ~ 5 °C / min, and then 550 °C to maintain 1 ~ 6 hours, and finally natural cooling.

[0035] (2) Preparation of carbon and nitrogen aerogel based on sodium hydroxide alkali heat, hereinafter referred to as CNA-Na preparation: 0.1~1.5g BCN in 10~30mL of NaOH solution with a concentration of 1~4M maintain 40~80°C reflux stirring for 1~15h, take out ultrasound every 3~6 hours for one hour, wash and centrifuge, and let the sample stand for 15~30 hours to obtain a carbon...

Embodiment 1

[0039] Example 1, based on sodium hydroxide alkali heat preparation of carbon and nitrogen hydrogel

[0040] (1) Preparation of carbon nitride in the bulk phase, hereinafter referred to as BCN: dicyanamide and thiourea are mixed uniformly according to the mass ratio of 4:1 and calcined in a muffle furnace. The heating procedure is 30 °C to 300 °C heating rate of 8 °C / min, 300 °C to 500 °C heating rate of 2 °C / min, 500 °C to 550 °C heating rate of 1 °C / min, then 550 °C for 4 hours, and finally natural cooling.

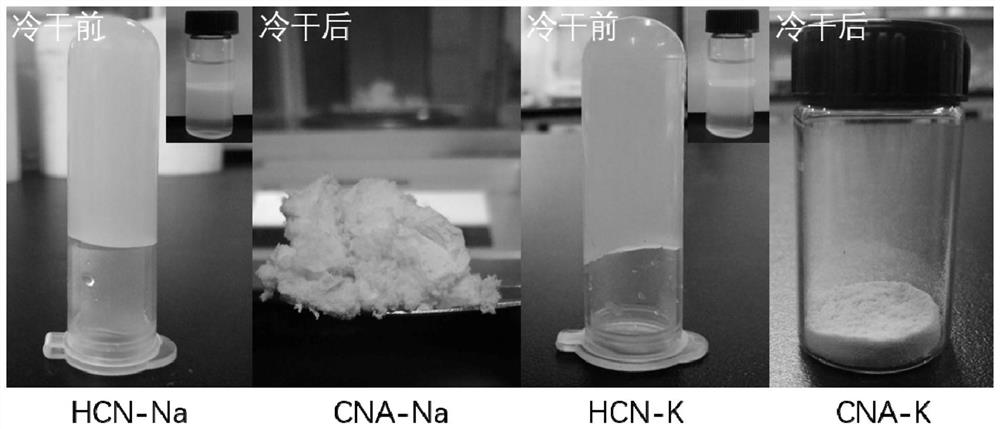

[0041] (2) Preparation of carbon and nitrogen hydrogel based on sodium hydroxide alkali heat, hereinafter referred to as HNA-Na preparation: 0.5g BCN in 20mL concentration of 3M NaOH solution to maintain 60 °C reflux stirring for 10h, in the fifth hour at the time of ultrasonic one hour, wash centrifugation, the sample is left for 15 hours to obtain carbon nitrogen hydrogel HCN-Na.

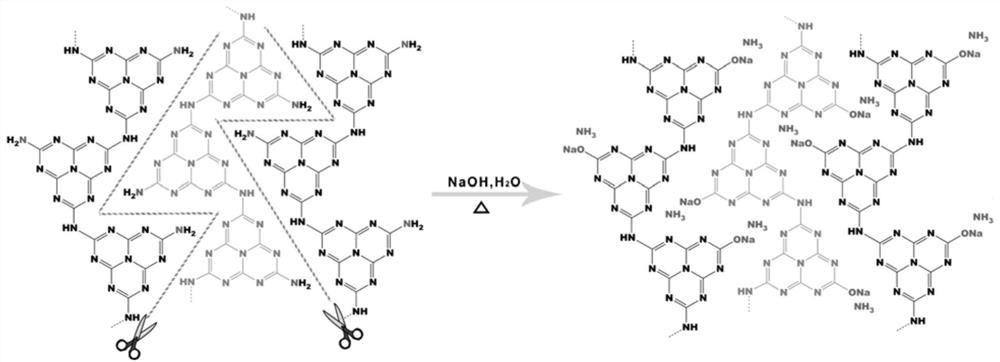

[0042] as Figure 1 As shown, under alkaline thermal conditions, the hydroxyl groups of w...

Embodiment 2

[0043] Example 2, based on sodium hydroxide alkali heat preparation of carbon nitrogen aerogel

[0044] (1) Preparation of carbon nitride in the bulk phase, hereinafter referred to as BCN: dicyanamide and thiourea are mixed uniformly according to the mass ratio of 4:1 and calcined in a muffle furnace. The heating procedure is 30 °C to 300 °C heating rate of 8 °C / min, 300 °C to 500 °C heating rate of 2 °C / min, 500 °C to 550 °C heating rate of 1 °C / min, then 550 °C for 4 hours, and finally natural cooling.

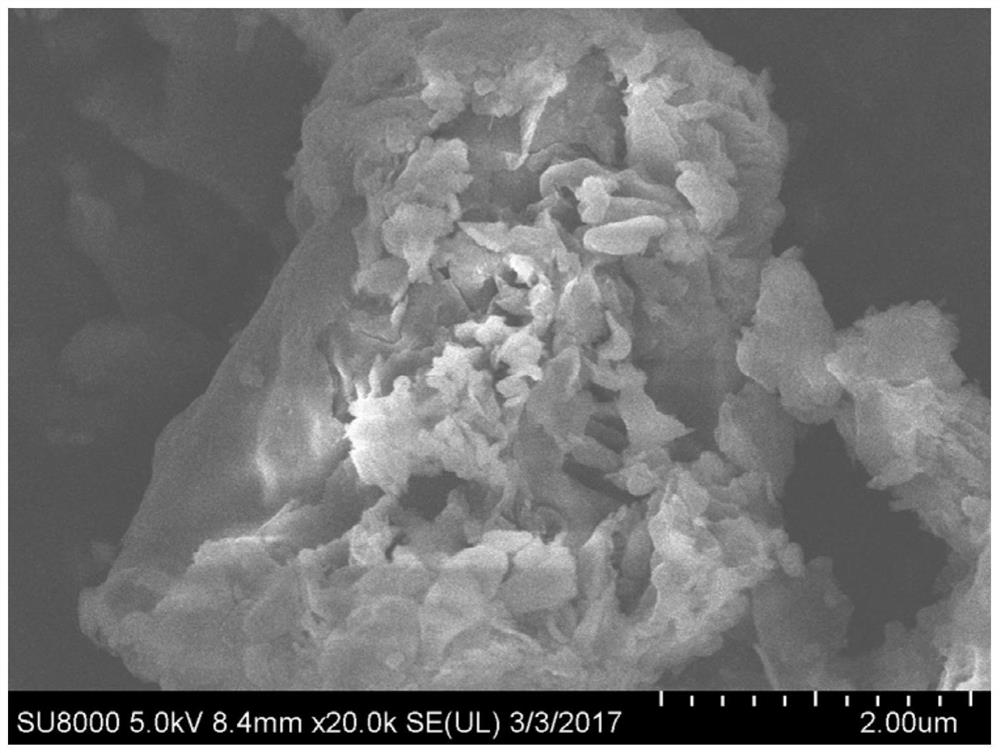

[0045] (2) Preparation of carbon and nitrogen aerogel based on sodium hydroxide alkali heat, hereinafter referred to as CNA-Na preparation: 0.5g BCN in 20mL concentration of 3M NaOH solution to maintain 60 °C reflux stirring for 10h, in the fifth hour to take out the ultrasound for one hour, wash centrifugation, the sample is left for 15 to 30 hours after the yield of carbon and nitrogen hydrogel, referred to as HCN-Na. The above HCN-Na is freeze-dried, and the freeze-drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com