Cationic poly-prodrug polymer as well as preparation method and application thereof

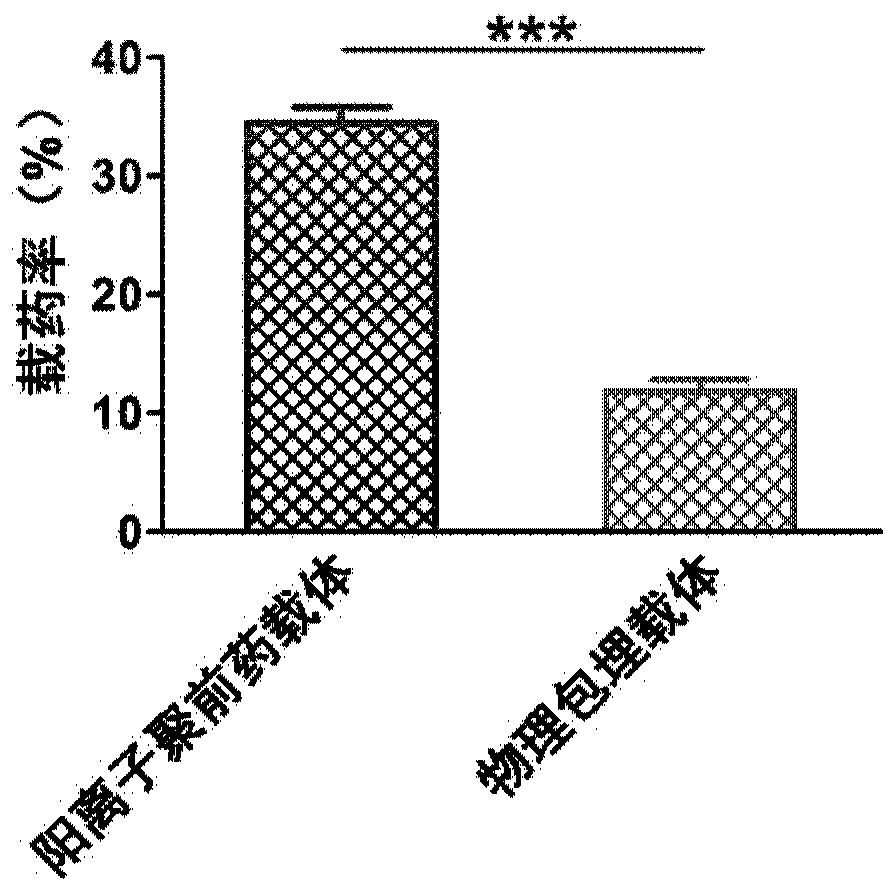

A technology of cationic polymers and polymers, which is applied in the direction of nano-drugs, pharmaceutical formulations, drug combinations, etc., can solve the problems of low drug-loading rate of carriers, obstacles in practical application, and increase the metabolic burden of patients, so as to achieve simple components and improve drug-loading. rate, the effect of reducing the metabolic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] When X of PCB-L-X is a small molecule drug containing hydroxyl or amino group (X-NH 2 , X-OH), when L is a single bond, the preparation method comprises the steps:

[0053] Add PCB to the first organic solvent, then add catalyst and X, stir and react to obtain a mixed solution containing polymer PCB-L-X;

[0054] Carrying out the first dialysis on the mixed solution containing the polymer PCB-L-X, and freeze-drying to obtain the PCB-L-X polymer;

[0055] When X of PCB-L-X is a small molecule drug (X-COOH) containing a carboxyl group, and L is a connecting molecule containing a bifunctional group, the preparation method includes the following steps:

[0056] Add X to the first organic solvent, then add catalyst and PCB-L, stir and react to obtain a mixed solution containing polymer PCB-L-X;

[0057] Perform the first dialysis on the mixed solution containing the polymer PCB-L-X, and freeze-dry to obtain the PCB-L-X polymer.

[0058] In the embodiment of the present in...

Embodiment 1

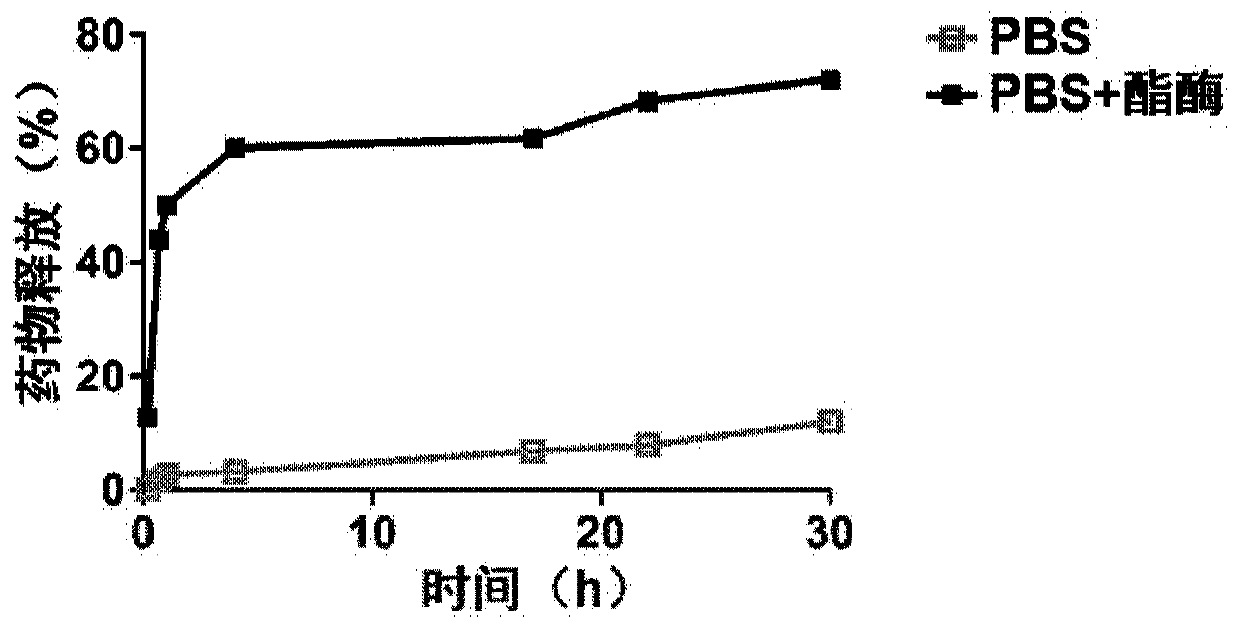

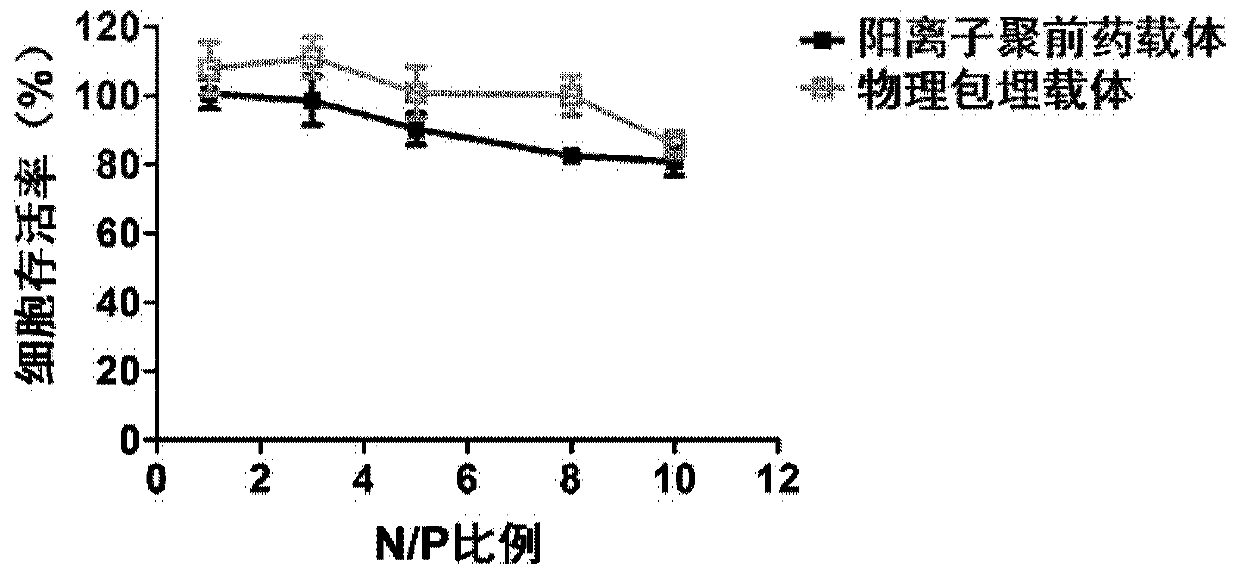

[0093] Example 1: Preparation of gene therapy drug and small molecule drug camptothecin combined delivery carrier

[0094] Dissolve 6mg of cyanoisopropyl dithiobenzoate, 311.1mg of carboxybetaine methacrylate (CB), and 1.5mg of azobisisobutyronitrile in methanol, remove the oxygen in the reaction flask and the mixed solution, and place in nitrogen Under protection, the reaction was stirred at 60°C for 24h. Carry out dialysis 24 hours with water as external phase, freeze-dry to obtain the polycarboxybetaine methacrylate (PCB) that theoretical polymerization degree is 50 50 ).

[0095] 40mg of polycarboxybetaine methacrylate (PCB) with a degree of polymerization of 50 50 ), 255.8 mg of 4-dimethylaminopyridine and 481.8 mg of 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride were dissolved in dimethylsulfoxide. After dissolving 303.8 mg of camptothecin (CPT) in dimethyl sulfoxide, the mixture was added dropwise, and stirred for 48 hours at 25°C. The product was dialyz...

Embodiment 2

[0097] Example 2: Preparation of gene therapy drug and small molecule drug simvastatin combined delivery carrier

[0098] Adopt the preparation PCB method described in embodiment 1 to prepare the polycarboxybetaine methacrylate (PCB) that theoretical polymerization degree is 50 50 ).

[0099] 400mg of polycarboxybetaine methacrylate (PCB) with a degree of polymerization of 50 50 ), 255.8 mg of 4-dimethylaminopyridine and 518.5 mg of dicyclohexylcarbodiimide were dissolved in dimethylsulfoxide. 730.2mg simvastatin (SIM 30 ) was dissolved in dimethyl sulfoxide, and the mixture was added dropwise, and stirred and reacted for 48 hours at 25°C. The product was dialyzed for 24 hours with dimethyl sulfoxide and water as the external aqueous phase, and freeze-dried for 48 hours to obtain the final PCB 20 -SIM 30 product.

[0100] At 25°C, the cationic polyprodrug polymer molecule PCB 20 - Simvastatin (SIM 30 ) was dissolved in dimethyl sulfoxide at a concentration of 1 mg / mL. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com