A green light-responsive polymer nano drug carrier

A nano-drug carrier and polymer technology, applied in the field of biomedical materials, can solve the problems of limiting the clinical application of polymer nano-drug carriers, and achieve the effects of avoiding light damage, large drug loading, and realizing release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

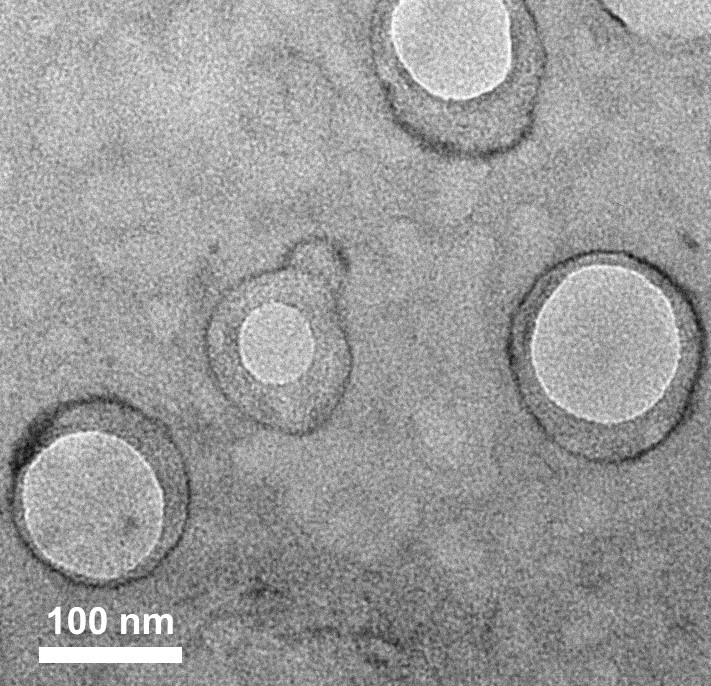

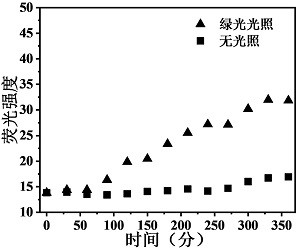

Image

Examples

Embodiment 1

[0029] (1) Preparation of furan derivatives: Dissolve 1.51g of Michaelis acid or 1,3-dimethylbarbituric acid and 0.961g of furfural in 30mL of water, react at room temperature for 16h; after the reaction is completed, filter and wash with water, A yellow solid was obtained; the yellow solid was redissolved in dichloromethane, washed successively with saturated sodium bisulfite solution, ultrapure water, saturated sodium carbonate solution and saturated sodium chloride solution; finally dried over anhydrous magnesium sulfate, filtered and rotary evaporation treatment to obtain furan derivatives;

[0030] (2) Preparation of polyethylene glycol-b-poly(hexyl acrylate-co-pentafluorophenyl methacrylate): 1 part of 2-(dodecyltrithiocarbonate)-2-methyl Polyethylene glycol monomethyl ether propionate, 0.05 parts of azobisisobutyronitrile, 4 parts of pentafluorophenyl methacrylate, and 40 parts of hexyl acrylate were dissolved in 1 mL of dioxane, and reacted at 60 ° C for 2 h; After co...

Embodiment 2

[0035] (1) Preparation of furan derivatives: Dissolve 1.51g of Michaelis acid or 1,3-dimethylbarbituric acid and 0.961g of furfural in 30mL of water, and react at room temperature for 16h; after the reaction is completed, filter and wash with water. A yellow solid was obtained; the yellow solid was redissolved in dichloromethane, washed successively with saturated sodium bisulfite solution, ultrapure water, saturated sodium carbonate solution and saturated sodium chloride solution; finally dried over anhydrous magnesium sulfate, filtered and rotary evaporation treatment to obtain furan derivatives;

[0036](2) Preparation of polyethylene glycol-b-poly(hexyl acrylate-co-pentafluorophenyl methacrylate): 5 parts of 2-(dodecyltrithiocarbonate group)-2-methyl Polyethylene glycol monomethyl ether propionate, 0.1 part of azobisisobutyronitrile, 5 parts of pentafluorophenyl methacrylate, and 60 parts of hexyl acrylate were dissolved in 5 mL of dioxane, and reacted at 75 ° C for 15 h; ...

Embodiment 3

[0041] (1) Preparation of furan derivatives: Dissolve 1.51g of Michaelis acid or 1,3-dimethylbarbituric acid and 0.961g of furfural in 30mL of water, react at room temperature for 16h; after the reaction is completed, filter and wash with water, A yellow solid was obtained; the yellow solid was redissolved in dichloromethane, washed successively with saturated sodium bisulfite solution, ultrapure water, saturated sodium carbonate solution and saturated sodium chloride solution; finally dried over anhydrous magnesium sulfate, filtered and rotary evaporation treatment to obtain furan derivatives;

[0042] (2) Preparation of polyethylene glycol-b-poly(hexyl acrylate-co-pentafluorophenyl methacrylate): 10 parts of 2-(dodecyltrithiocarbonate group)-2-methyl Polyethylene glycol monomethyl ether propionate, 0.2 parts of azobisisobutyronitrile, 8 parts of pentafluorophenyl methacrylate, and 80 parts of hexyl acrylate were dissolved in 10 mL of dioxane, and reacted at 90 ° C for 30 h; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com