Method for producing yeast cycloastragenol polypeptide mixture and its anti-aging application

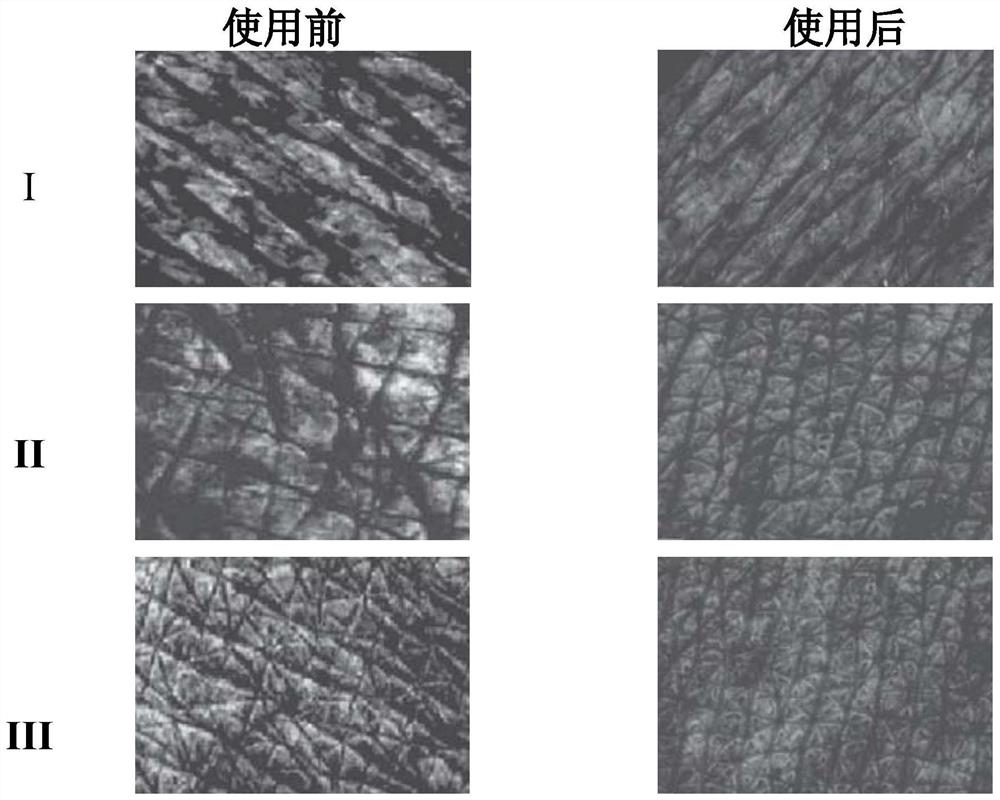

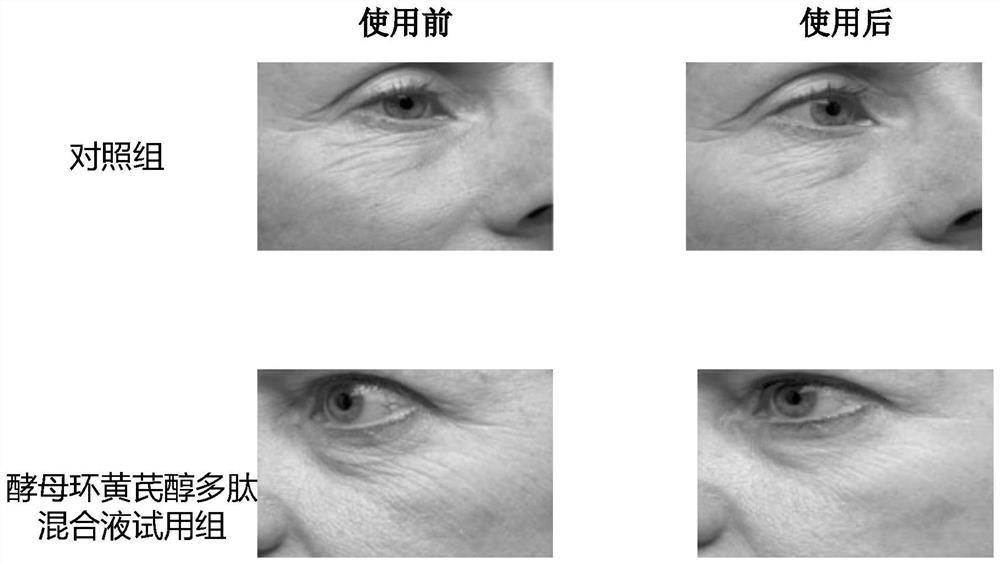

A technology of cycloastragalus and mixed solution, which is applied in the fields of biotechnology and cosmetics, can solve the problems of non-compliance with safety requirements, easy contamination of microorganisms, long time period, etc., and achieves diluting static and dynamic lines of epidermis, supplementing nutrient elements, delaying Effects of skin aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The fermentation process of embodiment 1 Kluyveromyces lactis XT82

[0033] The preserved Kluyveromyces lactis (Kluyveromyces lactis) XT82 was inoculated into 3-10ml YPD liquid medium, and the temperature was 30°C, and the rotation speed was 250rpm for continuous cultivation for 48 hours; Received in 1-10L YPD liquid culture medium, cultured continuously for 48-72 hours at a temperature of 30°C and a rotation speed of 250rpm; after the cultivation, centrifuged at a rotation speed of 3000-8000rpm for 10-30min to collect the cells; , YPD liquid medium:

[0034] 10 grams of yeast extract and 20 grams of peptone in 900ml of deionized water, sterilized at 121°C for 20 minutes; after cooling to about 60°C, add 50ml of filtered sterilized 40% glucose solution, and mix well.

Embodiment 2

[0035] Example 2 Preparation of Crude Enzyme Solution

[0036] The cells collected in Example 1 were washed 2-3 times with deionized water. Add 0.05-0.5 L of deionized water to suspend the cells, and place them in a high-pressure homogenizer at a pressure of 1500-2000 bar to break the cells. Incubate the broken cells at 95°C for 30 minutes, and after the proteins with intolerance to high temperature are completely denatured, centrifuge at 5,000-10,000 rpm for 30 minutes, collect the supernatant, which is the crude enzyme solution, and store at 4°C.

Embodiment 3

[0037] Example 3 Production method of yeast cycloastragenol polypeptide mixture 1

[0038] 1) Take 1 L of the enzyme solution in Example 2, add 40 grams of Astragalus extract containing 5% astragaloside IV, stir and react at a temperature of 70-80° C. for 1-3 hours; obtain a reaction liquid;

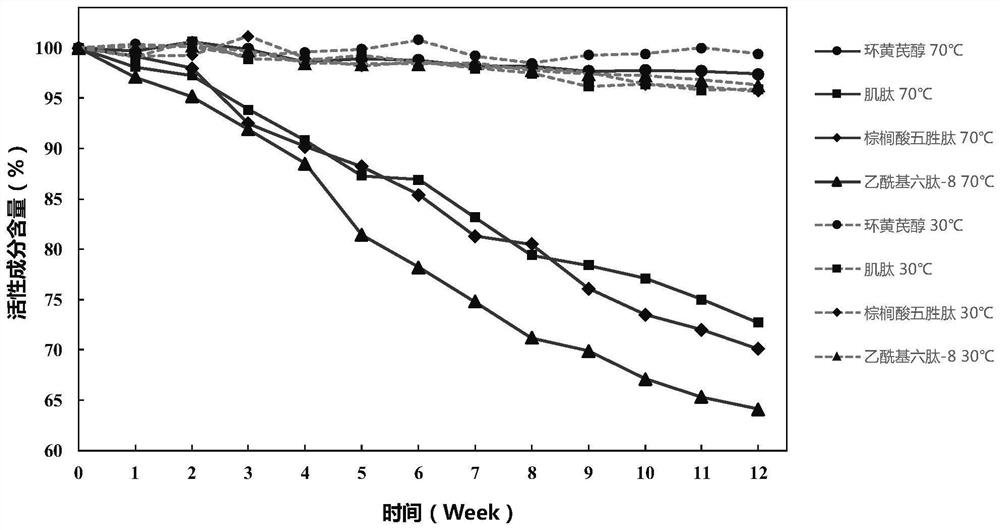

[0039] 2) Then add 15-30 times of water to the reaction liquid to dilute, then cool down to 25-40°C, and then add carnosine (Cas: 305-84-0) and palmitic acid pentapeptide (Cas: 214047-00-4) in sequence and acetyl hexapeptide-8 (Cas: 616204-22-9); obtain yeast cycloastragenol polypeptide mixture; store at -20°C;

[0040] Wherein, in the yeast cycloastragenol polypeptide mixture, the content of cycloastragenol is 0.01%,

[0041] The content of carnosine is 100ppm,

[0042] The content of palmitic acid pentapeptide is 50ppm,

[0043] The content of acetyl hexapeptide-8 was 50 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com