Preparation method of heterogeneous integrated monocrystal diamond film

A diamond and single crystal technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor crystal quality, many diamond film defects, and difficult processing, etc., and achieve the effect of high single crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

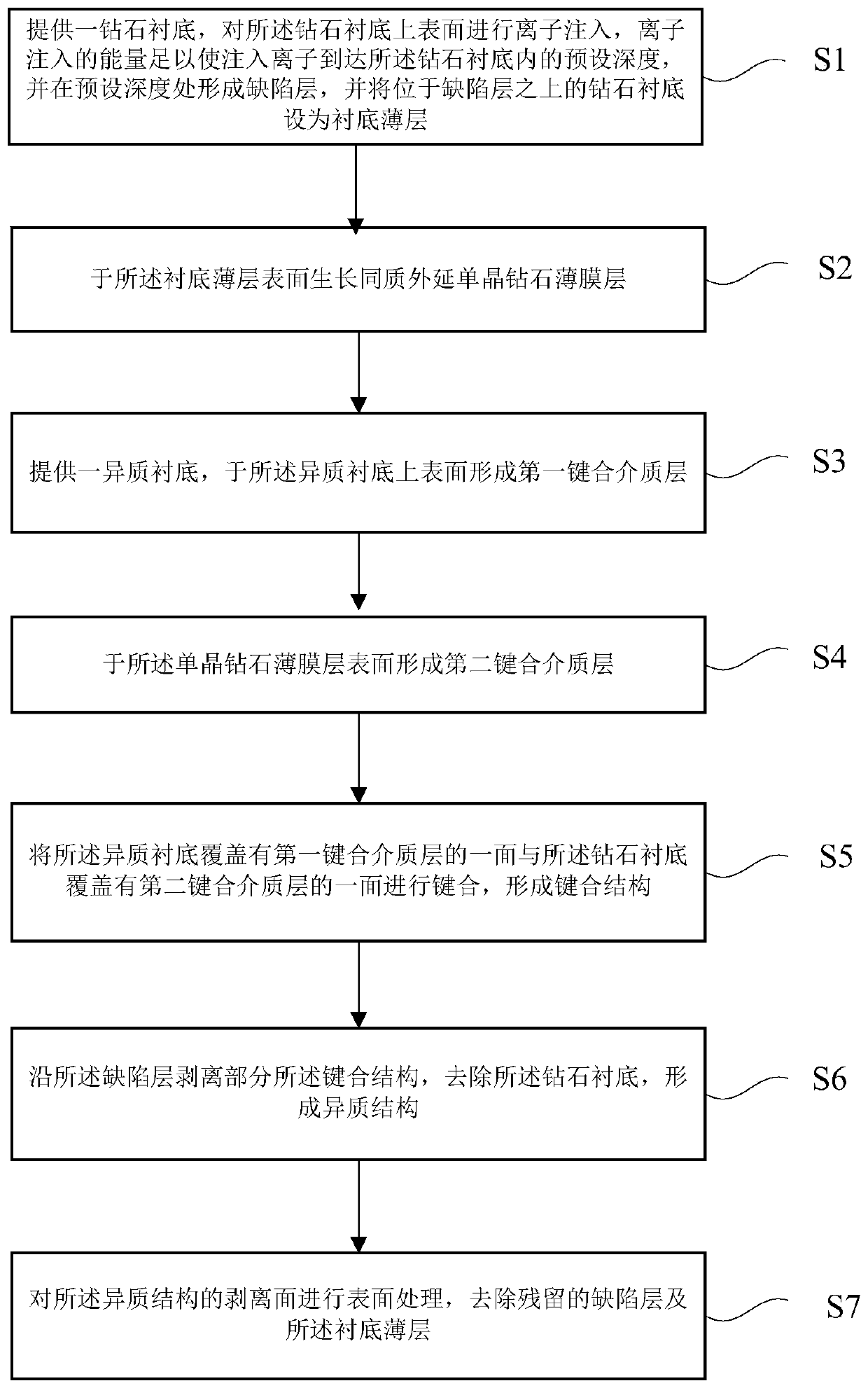

[0061] Such as Figure 1-9 As shown, this embodiment provides a method for preparing a heterogeneously integrated single-crystal graphene film.

[0062] see figure 1, the preparation method of the heterogeneously integrated single-crystal graphene film provided in this embodiment at least includes the following steps:

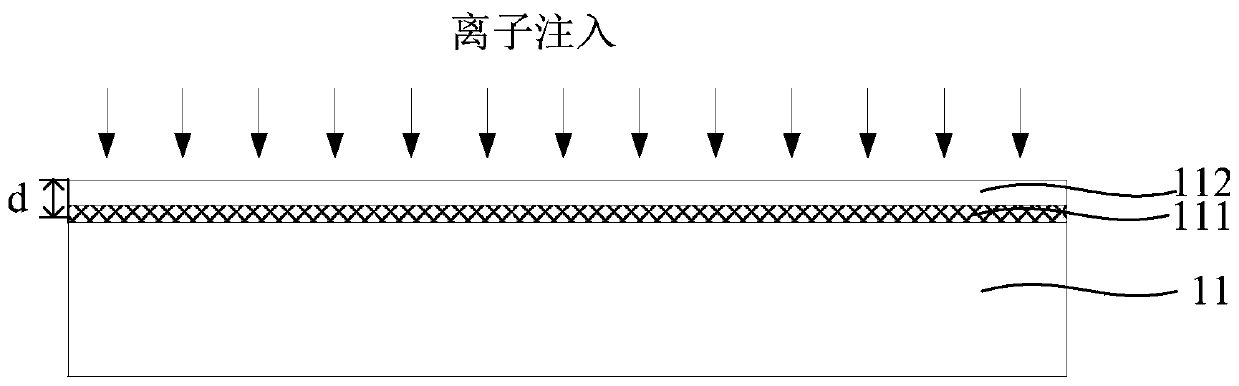

[0063] S1: Provide a diamond substrate, perform ion implantation on the upper surface of the diamond substrate, the energy of the ion implantation is sufficient to make the implanted ions reach a preset depth in the diamond substrate, form a defect layer at the preset depth, and The diamond substrate above the defect layer is set as a substrate thin layer;

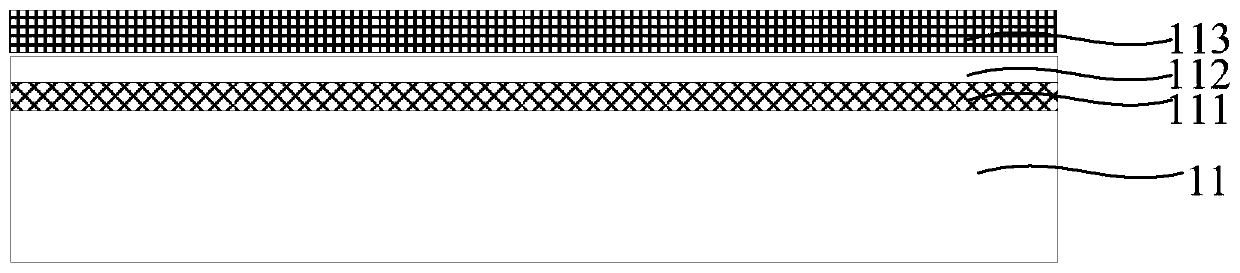

[0064] S2: growing a homoepitaxial single crystal diamond film layer on the surface of the diamond substrate thin layer;

[0065] S3: forming a first bonding medium layer on the surface of the single crystal diamond thin film layer;

[0066] S4: providing a heterogeneous substrate, forming a second bond...

Embodiment 2

[0087] Such as Figures 10-18 As shown, this embodiment provides a method for preparing a heterogeneously integrated single-crystal graphene film,

[0088] see Figure 10 , the present embodiment provides a method for preparing a heterogeneously integrated single crystal diamond thin film, comprising the following steps:

[0089] S1: Provide a diamond substrate, perform ion implantation on the upper surface of the diamond substrate, the energy of the ion implantation is sufficient to make the implanted ions reach a preset depth in the diamond substrate, form a defect layer at the preset depth, and The diamond substrate above the defect layer is set as a substrate thin layer;

[0090] S2: forming a first bonding medium layer on the upper surface of the diamond substrate;

[0091] S3: providing a heterogeneous substrate, forming a second bonding medium layer on the upper surface of the heterogeneous substrate;

[0092] S4: bonding the side of the diamond substrate covered wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com