Low-gram-weight high-strength corrugated core paper and preparation process thereof

A corrugated medium paper and preparation technology, which is applied in the field of papermaking, can solve the problems of high cost, lack of competitive advantage, failure to meet requirements, and occurrence of holes, etc., to save the flotation process, reduce the amount of glue used, and reduce power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

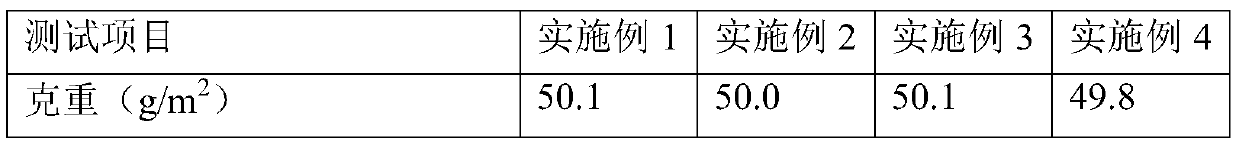

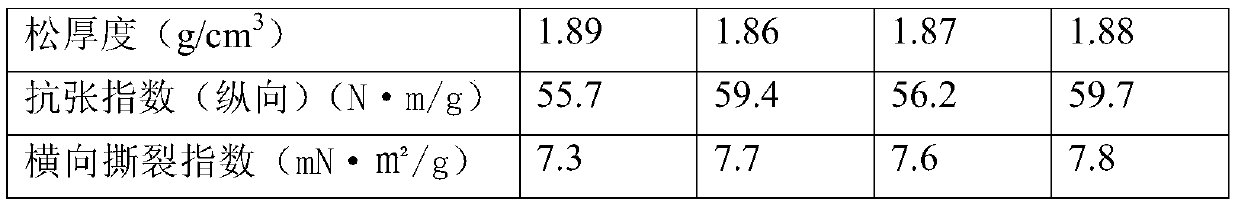

Embodiment 1

[0032] The low grammage high-strength corrugated medium paper prepared in this embodiment, its raw materials are calculated by weight, including domestic waste containerboard: 80 parts, imported 8# waste paper (U.S. 8# waste paper) 20 parts;

[0033] The preparation process includes the following steps: crushing, high-concentration desanding, rough screening, low-concentration desanding, papermaking, etc., and the pulp slag discharged from the rough screening is returned to high-concentration desanding for reuse, among which:

[0034] After mixing the waste paper in proportion, add water to adjust it to a concentration of 15%, add sodium hydroxide solution (mass concentration of 27.5%) according to the amount of 5kg / ton of dry waste paper, and use a drum hydropulper to disintegrate and remove plastics Large pieces of impurities such as paper; add stickies to the crushed slurry to control enzyme treatment, the amount of sticky control enzyme added is 0.05kg / ton of paper; then th...

Embodiment 2

[0037] The low grammage and high-strength corrugated medium paper prepared in this embodiment, its raw materials are calculated by weight, including domestic waste containerboard: 70 parts, imported 8# waste paper (US 8# waste paper) 30 parts;

[0038] The preparation process includes the following steps: crushing, high-concentration desanding, rough screening, low-concentration desanding, papermaking, etc., and the pulp slag discharged from the rough screening is returned to high-concentration desanding for reuse, among which:

[0039] After mixing the waste paper in proportion, add water to adjust it to a concentration of 20%, add sodium hydroxide solution (mass concentration 27.5%) according to the amount of 10kg / ton of absolute dry waste paper, and use a drum hydropulper to disintegrate and remove plastics Paper and other large pieces of impurities; add stickies to the crushed slurry to control enzyme treatment, the amount of stickies to control enzymes is 0.08kg / ton of pap...

Embodiment 3

[0042] The low grammage and high-strength corrugated medium paper prepared in this embodiment, its raw materials are calculated by weight, including domestic waste containerboard: 75 parts, imported 8# waste paper (U.S. 8# waste paper) 25 parts;

[0043] The preparation process includes the following steps: crushing, high-concentration desanding, rough screening, low-concentration desanding, papermaking, etc., and the pulp slag discharged from the rough screening is returned to high-concentration desanding for reuse, among which:

[0044] After mixing the waste paper in proportion, add water to adjust to a concentration of 17.5%, add sodium hydroxide solution (mass concentration is 27.5%) according to the amount of 7.5kg / ton dry waste paper, and use a drum hydraulic pulper to disintegrate and remove Large pieces of impurities such as plastic paper; add stickies to the crushed slurry to control enzyme treatment, and the amount of stickies to control enzymes is 0.065kg / ton of paper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com