A preparation method of flexible piezoelectric nanogenerator based on perovskite polymer composite

A nanogenerator, flexible piezoelectric technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrospinning, etc., can solve the problems of easy decomposition and short service life of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

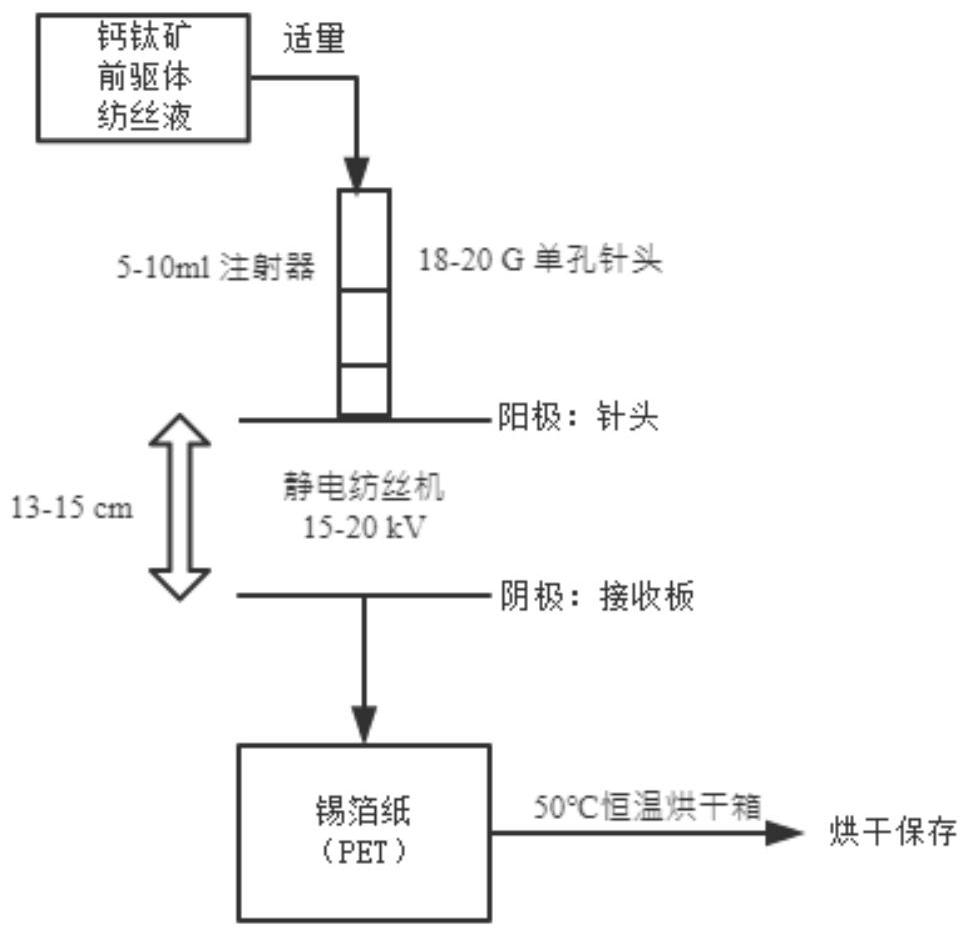

[0026] A method for preparing a flexible piezoelectric nanogenerator based on a perovskite polymer composite material provided by an embodiment of the present invention includes the following steps:

[0027] Step 1) Preparation of perovskite precursor solution: see figure 1 Add 0.1-3g of lead halide and cesium halide to 10-20ml N,N dimethylformamide, or add 0.1-3g of lead chloride and cesium chloride to 10-20ml dimethyl sulfoxide (DMSO) with a magnetic stirrer until completely dissolved. Then take 3ml more solution, add 0.4-3g polyvinylidene fluoride (PVDF), stir magnetically at 50°C until the polyvinylidene fluoride is completely dissolved into a clear and transparent solution, then add 0.2-0.4ml oleic acid and 0.2- 0.4ml of oleylamine, after magnetic stirring for half an hour, a clear, uniform and transparent perovskite precursor solution was obtained.

[0028] Step 2) Electrode preparation: use a flat screen printing machine to print the finger electrodes. The flat screen...

Embodiment 1

[0036] Step 1) raw material preparation: the weighed CsI, PbI 2 Put 0.1g and 0.1g into 10ml N, N dimethylformamide and acetone solvent respectively, after magnetic stirring is completely dissolved, take 3-8ml solution into another beaker, add 0.4g PVDF, magnetic stirring at 50°C After the solution was completely transparent, 0.3ml of oleic acid and 0.03ml of oleylamine were added, and after magnetic stirring for half an hour, a uniform and transparent perovskite precursor solution was obtained.

[0037] Step 2) Electrode preparation: Use a screen printing machine to fix the prefabricated screen printing screen on the screen printing machine, adjust the position between the scraper frame and the screen, and place the substrate PET at a suitable position on the transmission table , put the low-temperature silver paste on the screen to print the finger electrode, after printing, put it in an oven at 80-120°C for 0.5-1h to dry.

[0038] Step 3) Electrospinning composite fiber: us...

Embodiment 2

[0041] Step 1) raw material preparation: the weighed CsI, PbI 2 Put 0.2g and 0.2g into 10ml N, N dimethylformamide and 6ml acetone solvent respectively, after magnetic stirring is completely dissolved, take 3ml solution into another beaker, add 1.5g PVDF, and magnetically stir at 50°C until After the solution was completely transparent, 0.3ml of oleic acid and 0.03ml of oleylamine were added, and after magnetic stirring for half an hour, a uniform and transparent perovskite precursor solution was obtained.

[0042] Step 2) Electrode preparation: Use a screen printing machine to fix the prefabricated screen printing screen on the screen printing machine, adjust the position between the scraper frame and the screen, and place the substrate PET at a suitable position on the transmission table , Print low-temperature silver paste on the screen. Then put it in an oven at 80°C for 30 minutes to dry.

[0043] Step 3) Electrospinning composite fibers:

[0044] Use a 14G single-hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com