Binary doped modified sulfonated poly-ether-ether-ketone (SPEEK) proton exchange membrane (PEM) and preparation method thereof

A technology of sulfonated polyether ether ketone and proton exchange membrane, applied in electrical components, electrochemical generators, fuel cells, etc., can solve the problem of low proton conductivity, reduced mechanical strength, water absorption and swelling degree, and two-phase separation Not obvious and other problems, to achieve the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

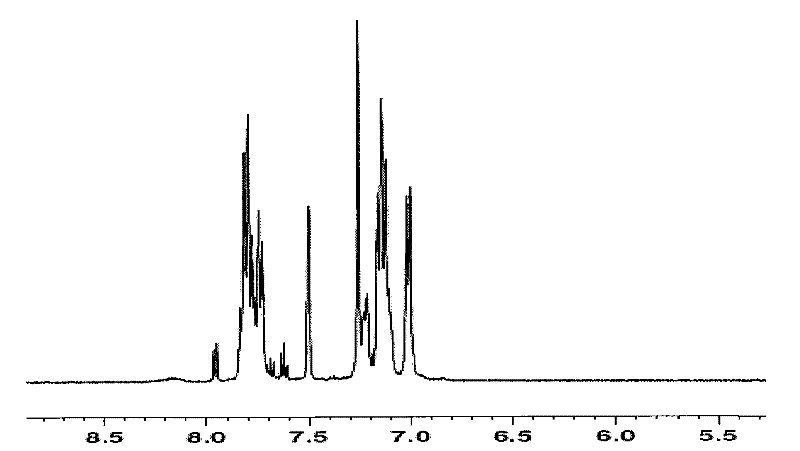

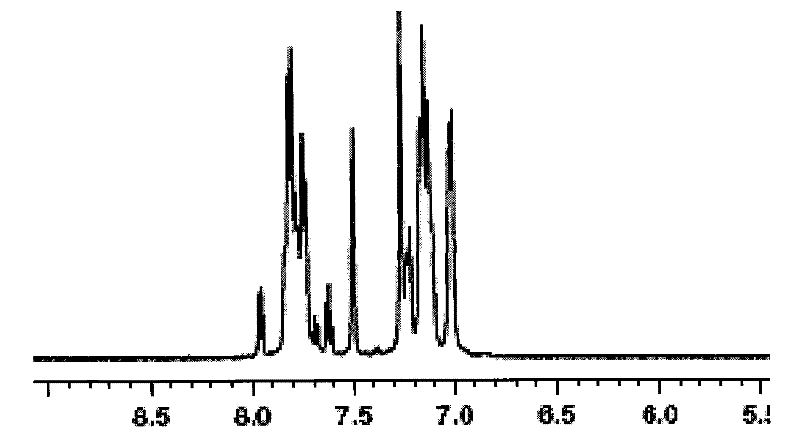

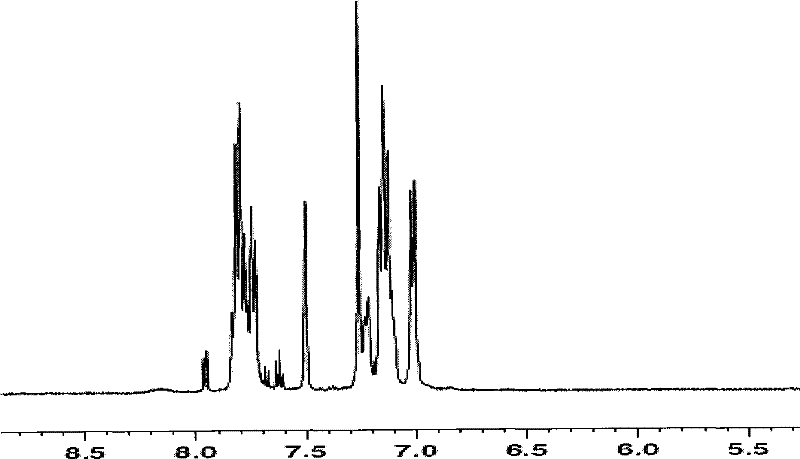

Image

Examples

Embodiment 1

[0027] Embodiment one: the composition formula and preparation process of the present embodiment are as follows:

[0028] 1. Formulation

[0029] A. Composite membrane matrix material: DS is 68.02% SPEEK material, and the mass percentage is 90%.

[0030] B. Binary doped solid: nano-CeO 2 、H 3 PW 12 o 40 , the mass percentage is 10%, where CeO 2 and H 3 PW 12 o 40 The molar ratio is 1:1.

[0031] 2. Synthesis of SPEEK material with DS of 68.02%: Add 20g of PEEK powder and 800ml of concentrated sulfuric acid into a 1L three-necked flask, and stir the reaction at 60°C for 9 hours. After the reaction solution is cooled to room temperature, pass the reaction solution through the glass Pour the funnel into 4.5L of ice-water mixture, after cooling, rinse with a large amount of deionized water for 6 times, then let it stand overnight with 4.5L of deionized water, then rinse with deionized water for 3 times, and filter out the pink A colored SPEEK solid was obtained, and the ...

Embodiment 2

[0035] Embodiment two: the composition formula and the preparation process of the present embodiment are as follows:

[0036] 1. Formulation

[0037] A. Composite membrane matrix material: DS is 61.79% SPEEK material, and the mass percentage is 85%.

[0038] B. Binary Doped Solid: Nano Y2 o 3 、H 3 PW 12 o 40 , the mass percentage is 15%, where Y 2 o 3 and H 3 PW 12 o 40 The molar ratio is 1:1.

[0039] 2. Synthesis of SPEEK: Add 25g of PEEK powder and 500ml of concentrated sulfuric acid into a 1L three-necked flask, and mechanically stir the reaction at 60°C for 6h. After the reaction solution is cooled to room temperature, pour the reaction solution through a glass funnel into 4.5L After cooling, rinse with a large amount of deionized water for 6 times, then let it stand overnight with 4.5L of deionized water, then rinse with deionized water for 3 times, filter out the pink SPEEK solid, and put The product was dried under vacuum at 100 °C for 24 h.

[0040] 3. Pre...

Embodiment 3

[0043] Embodiment three: the composition formula and the preparation process of the present embodiment are as follows:

[0044] 1. Formulation

[0045] A. Composite membrane matrix material: DS is 61.79% SPEEK material, and the mass percentage is 90%.

[0046] B. Binary Doped Solid: Nano Y 2 o 3 、H 3 PW 12 o 40 , the mass percentage is 10%, where Y 2 o 3 and H 3 PW 12 o 40 The molar ratio is 1:2.

[0047] 2. Synthesis of SPEEK: Add 25g of polyetheretherketone PEEK powder and 500ml of concentrated sulfuric acid into a 1L three-necked flask, and mechanically stir the reaction at 60°C for 6h. After the reaction solution is cooled to room temperature, pass the reaction solution through a glass funnel. Pour into 4.5L of ice-water mixture, after cooling, rinse with a large amount of deionized water for 6 times, then let it stand overnight with 4.5L of deionized water, then rinse with deionized water for 3 times, and filter out the pink SPEEK was solid, and the product wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com