Organic electroluminescence device

An electroluminescence device and luminescence technology, applied in the direction of electroluminescence light source, electric solid-state device, electric light source, etc., can solve the problems of upper limit of device operating temperature, influence of device stability, low glass transition temperature, etc., and achieve improvement Good production efficiency, good stability and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

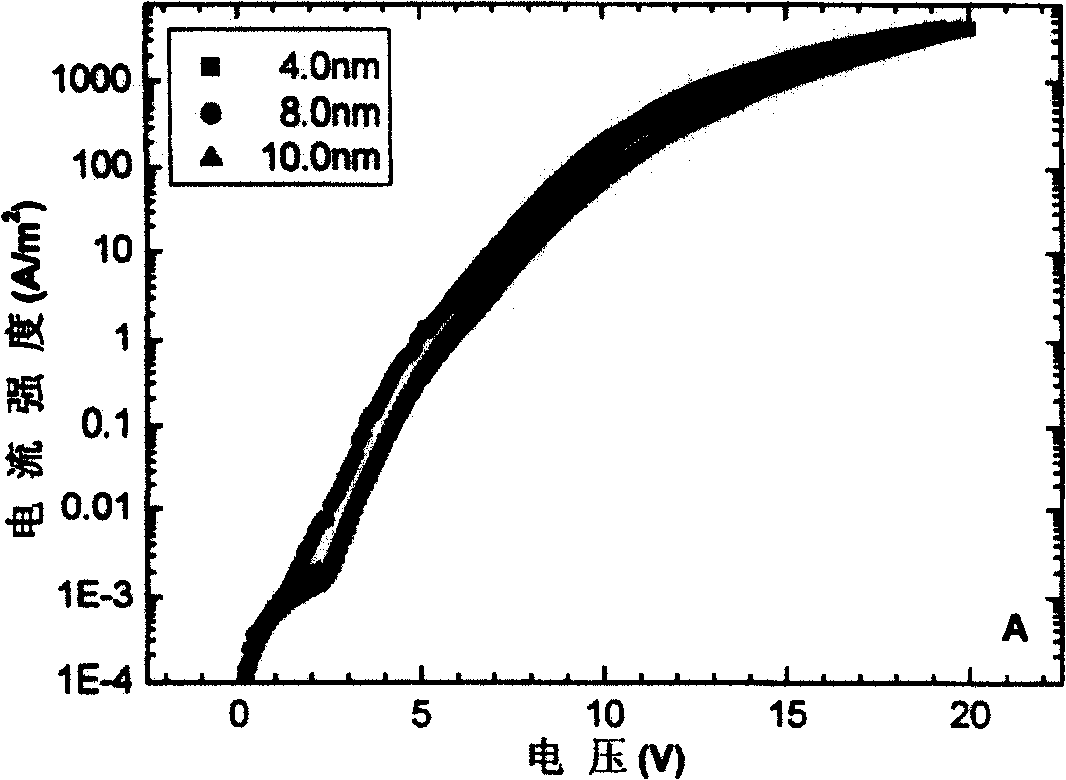

[0030] Embodiment 1-4 (device number OLED1-4)

[0031] Glass / anode / Alq 3 :DMQA / BAlq / LiF / Al (1)

[0032] Four organic electroluminescence devices having the above structural formula (1) were prepared, and the anodes of these four devices used different electrode materials. The specific preparation method is as follows:

[0033] ① Clean the glass substrate by using boiling detergent ultrasonic and deionized water ultrasonic method, and place it under the infrared lamp to dry, and evaporate a layer of anode material on the glass with a film thickness of 80-280nm;

[0034] ②Place the above-mentioned glass substrate with anode in a vacuum chamber, and evacuate to 1×10 -5 ~9×10 -3 On the anode layer film of Pa, continue to vapor-deposit a layer of Alq3 doped with DMQA as the organic light-emitting layer of the device, and use a dual-source vapor deposition method for doping. The ratio of the vapor deposition rate of Alq3 and DMQA is 10000: 1~ 100:2, the doping concentration of ...

Embodiment 5-7

[0040] Embodiment 5-7 (device number OLED5-7)

[0041] Glass / ITO / Teflon / Alq 3 :DMQA / Balq / LiF / Al (2)

[0042] Prepare 3 organic electroluminescent devices with the above structural formula (2), the specific steps of preparation are as follows:

[0043] ① Clean the ITO glass with a transparent conductive substrate with an anode by using boiling detergent ultrasonic and deionized water ultrasonic method, and place it under an infrared lamp for drying, in which the ITO film on the conductive substrate is used as the anode layer of the device , the sheet resistance of the ITO film is 5Ω~100Ω, and the film thickness is 80~280nm;

[0044] ②Put the above-mentioned cleaned and dried ITO glass in a vacuum chamber and vacuumize to 1×10 -5 ~9×10 -3 For Pa, a layer of Teflon is evaporated on the above ITO film as the hole injection layer of the device, the evaporation rate of the film is 0.01-0.2nm / s, and the film thickness is 0.5-20nm;

[0045] ③Continue to vapor-deposit a layer of A...

Embodiment 8-11

[0058] Embodiment 8-11 (device number OLED8-11)

[0059] Double-layer devices OLED8, OLED9, OLED10 and OLED11 were prepared by the same method as in Examples 5-7, and the electrodes of these four devices used different electrode materials from those in Examples 5-7. The structures and properties of the four OLEDs are shown in Table 4 below:

[0060] Table 4

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com