Medium borosilicate glass injection agent bottle for small-dose injection

A borosilicate glass and injection bottle technology, applied in electric furnaces, furnaces, feeding troughs, etc., can solve the problems of glass component volatilization, glass surface damage, unreasonable formula, etc., to avoid residues, reduce raw material volatilization, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A medium-borosilicate glass injection bottle for small-dose injections adopts a reasonable preparation formula to ensure low migration of aluminum, sodium, potassium, calcium and other elements.

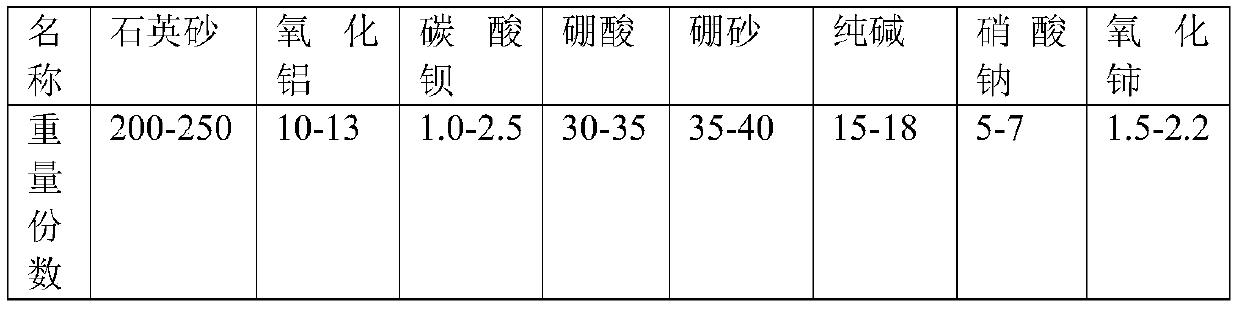

[0027] The technical solution adopted by the present invention to solve the technical problem is to provide a medium-borosilicate glass injection bottle for small dose injection, which is characterized in that it is composed of the following raw materials in parts by mass:

[0028]

[0029] The quartz sand is produced by Anhui Fengyang Zhongtian Mining Quartz Sand Factory.

[0030] The alumina mentioned above is produced by Shandong Aluminum Industry Co., Ltd.

[0031] Described soda ash is Shandong Haihua Group Co., Ltd.

[0032] The obtained product product quality index:

[0033]

Embodiment 2

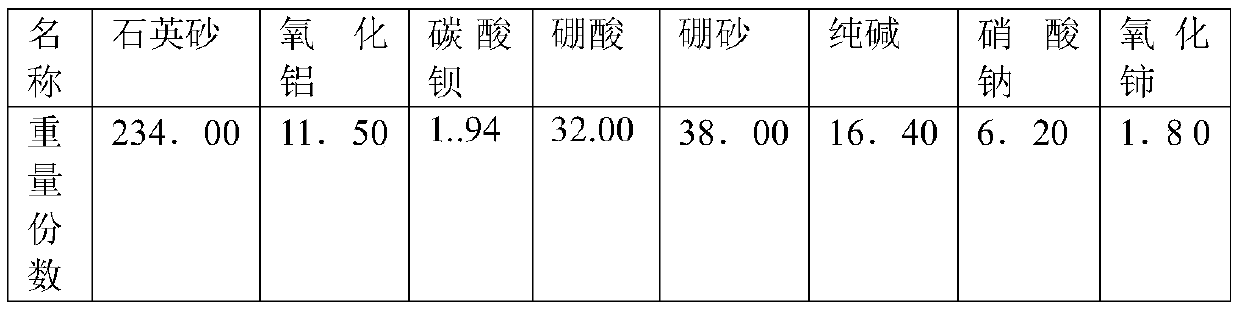

[0035] A medium borosilicate glass injection bottle for small dose injection, characterized in that it consists of the following raw materials in parts by mass:

[0036]

[0037] The quartz sand is produced by Anhui Fengyang Zhongtian Mining Quartz Sand Factory.

[0038] The alumina mentioned above is produced by Shandong Aluminum Industry Co., Ltd.

[0039] Described soda ash is Shandong Haihua Group Co., Ltd.

[0040] The obtained product product quality index:

[0041]

[0042]

Embodiment 3

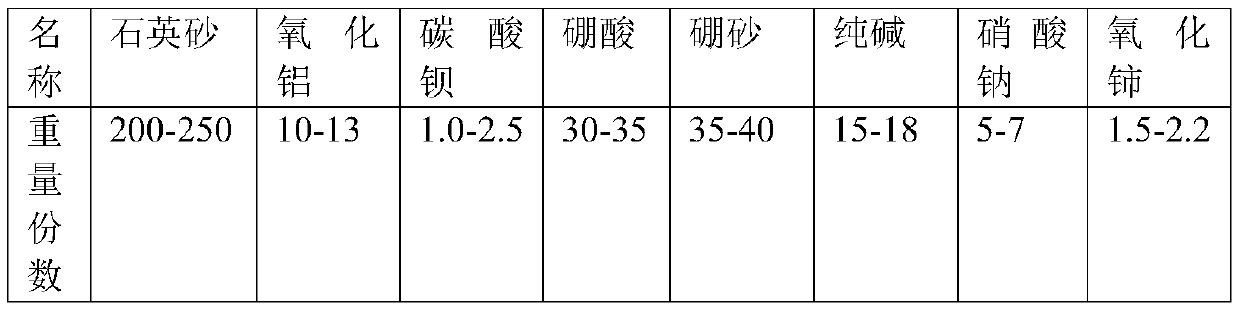

[0044] A medium borosilicate glass injection bottle for small dose injection, characterized in that it consists of the following raw materials in parts by mass:

[0045]

[0046] The quartz sand is produced by Anhui Fengyang Zhongtian Mining Quartz Sand Factory.

[0047] The alumina mentioned above is produced by Shandong Aluminum Industry Co., Ltd.

[0048] Described soda ash is Shandong Haihua Group Co., Ltd.

[0049] The obtained product product quality index:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com