Catalyst for preparing multi-walled carbon nanotubes, preparation method and application thereof

A technology of multi-walled carbon nanotubes and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problems of low carbon tube yield and poor crystallinity High, prone to explosion and other problems, to achieve the effect of improving space utilization, simple preparation method, and large metal loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A-30F

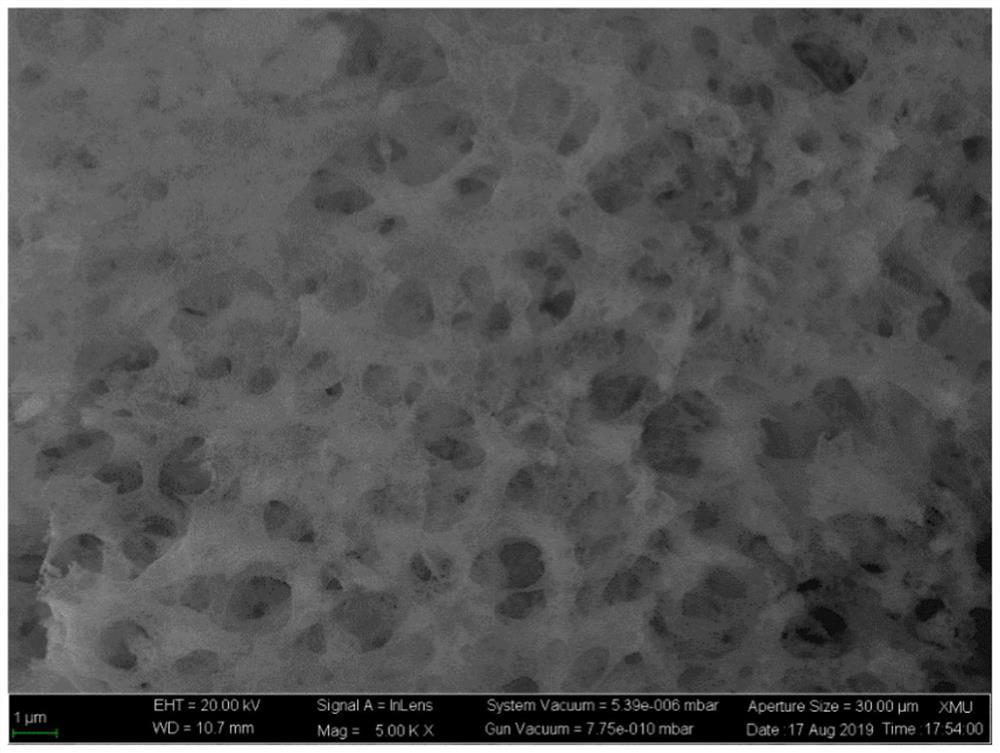

[0034] Example 1A-30Fe 15 -Mo / MgO catalyst

[0035] Dissolve 0.8761g of ammonium molybdate and 23.8386g of citric acid monohydrate in 15mL of deionized water, add 1.65mL of nitric acid and stir well, add 30.0715g of ferric nitrate nonahydrate and stir well, add 0.5g of urea and stir well, then add 10g of light oxidation Magnesium, the resulting mixture was continuously stirred for 180 minutes, then stirred and evaporated to dryness at 80°C for 300 minutes, the obtained solid was dried and foamed at 150°C for 3 hours, and then placed in a blast drying oven at 110°C to dry overnight, and the dried solid was ground into powder In a muffle furnace, the temperature is raised to 500°C for 180min at 2°C / min to obtain a composition of 30mol% Fe 15 -Mo / MgO catalyst, and recorded as A-30Fe 15 -Mo / MgO. The characterization results of the catalyst show that the MgO particle size is about 6.4nm, the pore structure is 0.51-1.80um, and the average pore diameter is 1.77μm. See Table 1 for ...

Embodiment 2B-20

[0037] Example 2B-20Fe 15 -Mo / MgO catalyst

[0038] Add 0.4764g of molybdenum oxide and 23.8386g of citric acid monohydrate to 15mL of deionized water, add 12.7238g of magnesium nitrate hexahydrate and stir evenly, add 20.0676g of ferric nitrate nonahydrate and stir evenly, add 1mL of concentrated ammonia water and stir evenly, then add 8g of light Magnesium oxide, the resulting mixture was stirred for 30 minutes, then stirred and evaporated to dryness at 120°C for 30 minutes, the obtained solid was dried and foamed at 80°C for 12 hours, and then placed in a blast drying oven at 110°C to dry overnight, and the dried solid was ground into Powder, in a muffle furnace at 2°C / min to 450°C and roasted for 300min to obtain a composition of 20mol% Fe 15 -Mo / MgO catalyst, and recorded as B-20Fe 15 -Mo / MgO. The particle size of the catalyst MgO is about 13.8nm, the pore structure is 0.62-1.67μm, and the average pore size is 0.95μm. See Table 1 for other characterization results.

...

Embodiment 3

[0040] Example 3C-10Fe 20 - Mo / MgO catalyst

[0041] Dissolve 0.4046g of molybdenum acetylacetonate and 27.0145g of citric acid monohydrate in 15mL of deionized water, add 12.7238g of magnesium nitrate hexahydrate and stir evenly, add 15.0357g of iron nitrate nonahydrate and stir evenly, add 1.0g of glycine (aminoacetic acid) and stir After uniformity, 31.3290g of basic magnesium carbonate was added, and the resulting mixture was stirred for 30 minutes, then stirred and evaporated to dryness at 120°C for 30 minutes, and the obtained solid was dried and foamed at 80°C for 12 hours, and then placed in a blast drying oven at 110°C to dry overnight. Grind the dried solid into powder, heat up to 600°C for 180min in a muffle furnace at 2°C / min to obtain a composition of 10mol% Fe 20 -Mo / MgO catalyst, and denoted as C-10Fe 20 -Mo / MgO. The particle size of catalyst MgO is about 15.8nm, the pore structure is 0.52-1.63μm, and the average pore size is 0.98μm. See Table 1 for other cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com