Antibacterial degradable composite material and application thereof in preparation of paper diapers

A composite material and polymer technology, used in the field of sanitary products, can solve the problems of slow degradation, not easy to degrade, and unfavorable environmental protection, and achieve the effects of large liquid absorption, convenient operation, and improved absorption rate and infiltration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

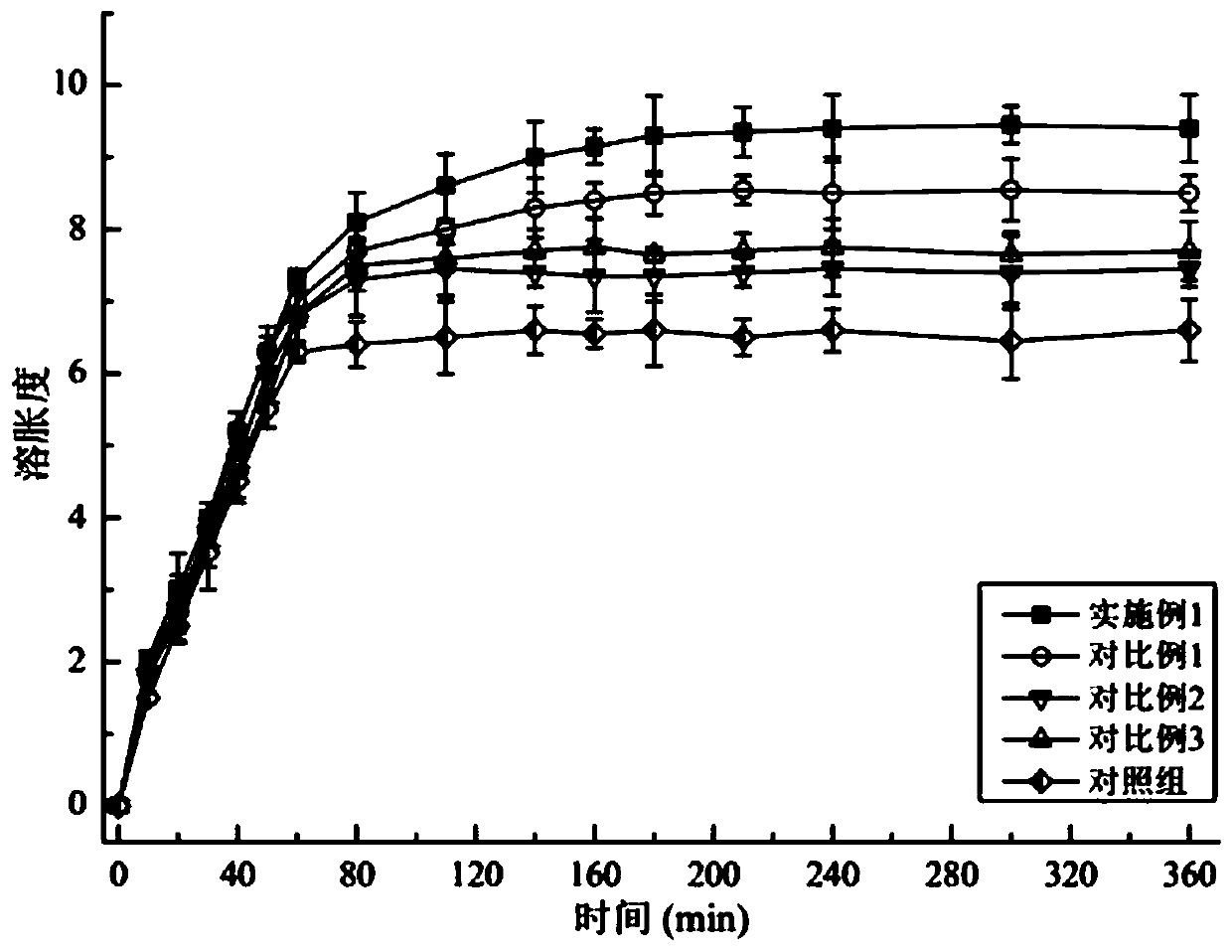

[0027] A preparation method of an antibacterial and degradable composite material, comprising: providing a polyaspartic acid / lignocellulose polymer network with water absorption; providing an antibacterial chitosan oligosaccharide viscose fiber, the chitosan oligosaccharide viscose fiber It is a polymer network support material; and, the polymer network and oligosaccharide viscose fiber are made into a non-woven composite material through a spunlace or needle punching process; the above-mentioned chitosan oligosaccharide viscose fiber is modified chitosan oligosaccharide and viscose The glue fiber is obtained by grafting and reacting with a gain agent and an environment with a pH of 6-8, and the above-mentioned gain agent is α-methacrylic acid and mercaptoacetic acid. The composite material prepared by the method has good antibacterial performance, fast absorption rate and infiltration rate, large liquid absorption capacity, longitudinal flow conductivity, and can preserve liqu...

Embodiment 1

[0047] A kind of preparation method of antibacterial degradable composite material, its specific steps are as follows:

[0048] (1) oligochitosan is dissolved in hot water to make a solution with a concentration of 5.5%. After being cooled to room temperature, sodium methacryl sulfonate with 23% weight of oligochitosan is added thereto and stirred to dissolve, then to it Add potassium persulfate with 4.5% weight of chitosan oligosaccharide, adjust the pH of the system to 7, heat up to 80°C and react for 4.5 hours to obtain the modified chitosan oligosaccharide solution;

[0049] (2) Add a sodium hydroxide solution with a concentration of 1 wt% to the viscose fiber at a bath ratio of 1:11, react at 85° C. for 45 minutes, wash with soft water until neutral, dry, and set aside;

[0050] (3) Add modified chitosan oligosaccharide solution to the viscose fiber at a ratio of 1:12, and then add 0.6% weight gain agent of chitosan oligosaccharide, adjust the pH of the system to 7, and k...

Embodiment 2

[0055] A kind of preparation method of antibacterial degradable composite material, wherein the difference with embodiment 1 is:

[0056] The addition of step (1) sodium methacrylate is 35% of chitosan weight;

[0057] Step (3) the amount of gain agent added is 0.75% of the chitosan weight, and the weight ratio of α-methacrylic acid and thioglycolic acid in the gain agent is 1:0.35;

[0058] Step (4) the weight ratio of lignocellulose and polyaspartic acid and crosslinking agent glutaraldehyde is 1:12:0.5;

[0059] Step (5) take polyaspartic acid / lignocellulose polymer network and chitosan oligosaccharide viscose fiber, alginate fiber and activated carbon fiber and make antibacterial and degradable composite material of non-woven fabric type through acupuncture process, above-mentioned The composite material includes 30wt% polyaspartic acid / lignocellulose polymer network, 60wt% oligochitosan viscose fiber, 5wt% alginate fiber and 5wt% activated carbon fiber;

[0060] Step (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com