Dynamic and static combined stirring system and process for preparing chromium salt by using chromite liquid phase oxidation method

A stirring system and static stirring technology, applied in the direction of chromium oxide/hydrate, mixer with rotating stirring device, silicate, etc., can solve the problems of difficult separation of chromium salt and alkali, difficulty in recovery, and influence on alkali recycling , achieve the effects of fast and efficient chromium salt clean production mode, enhanced fluid mixing and mass transfer, and large industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

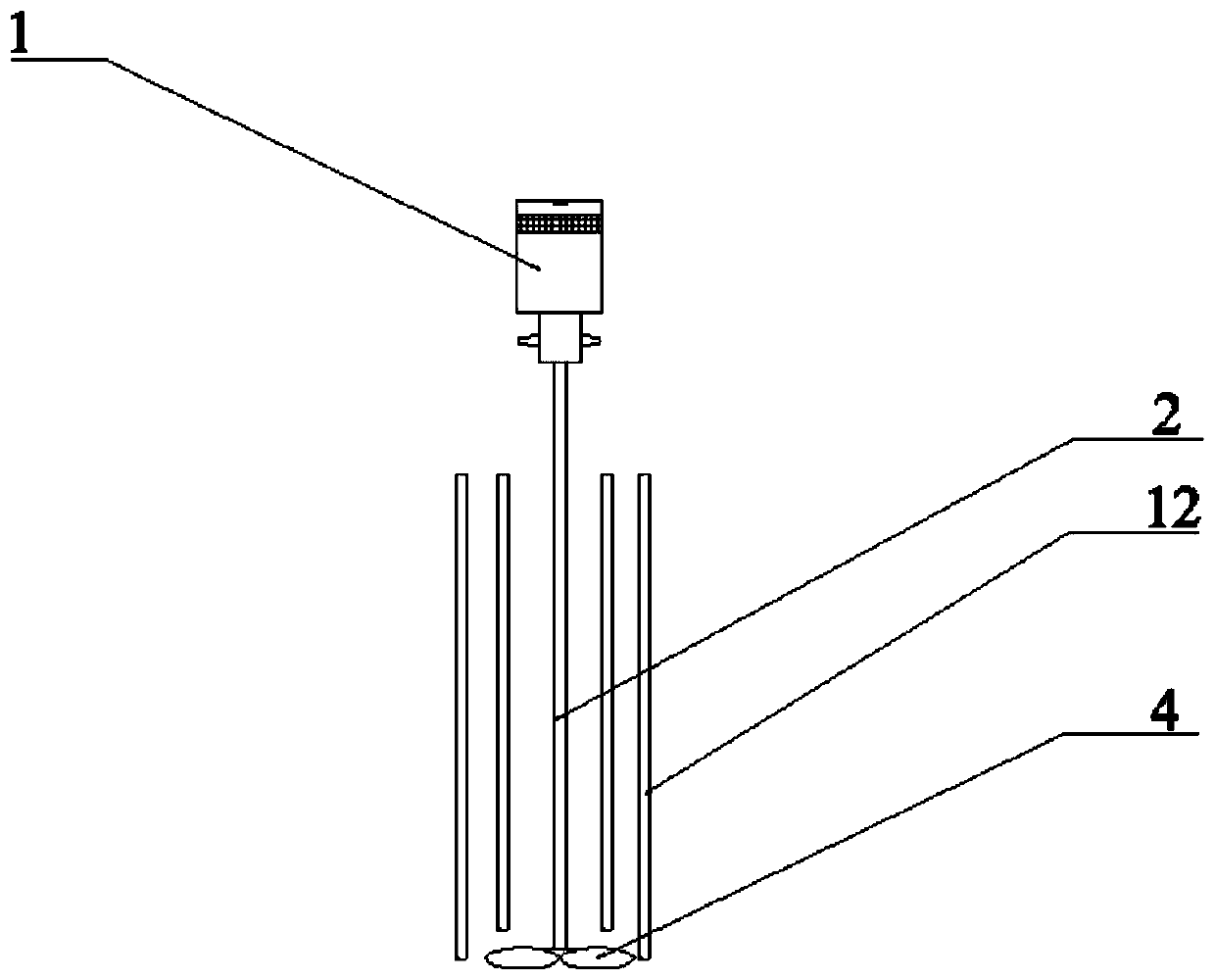

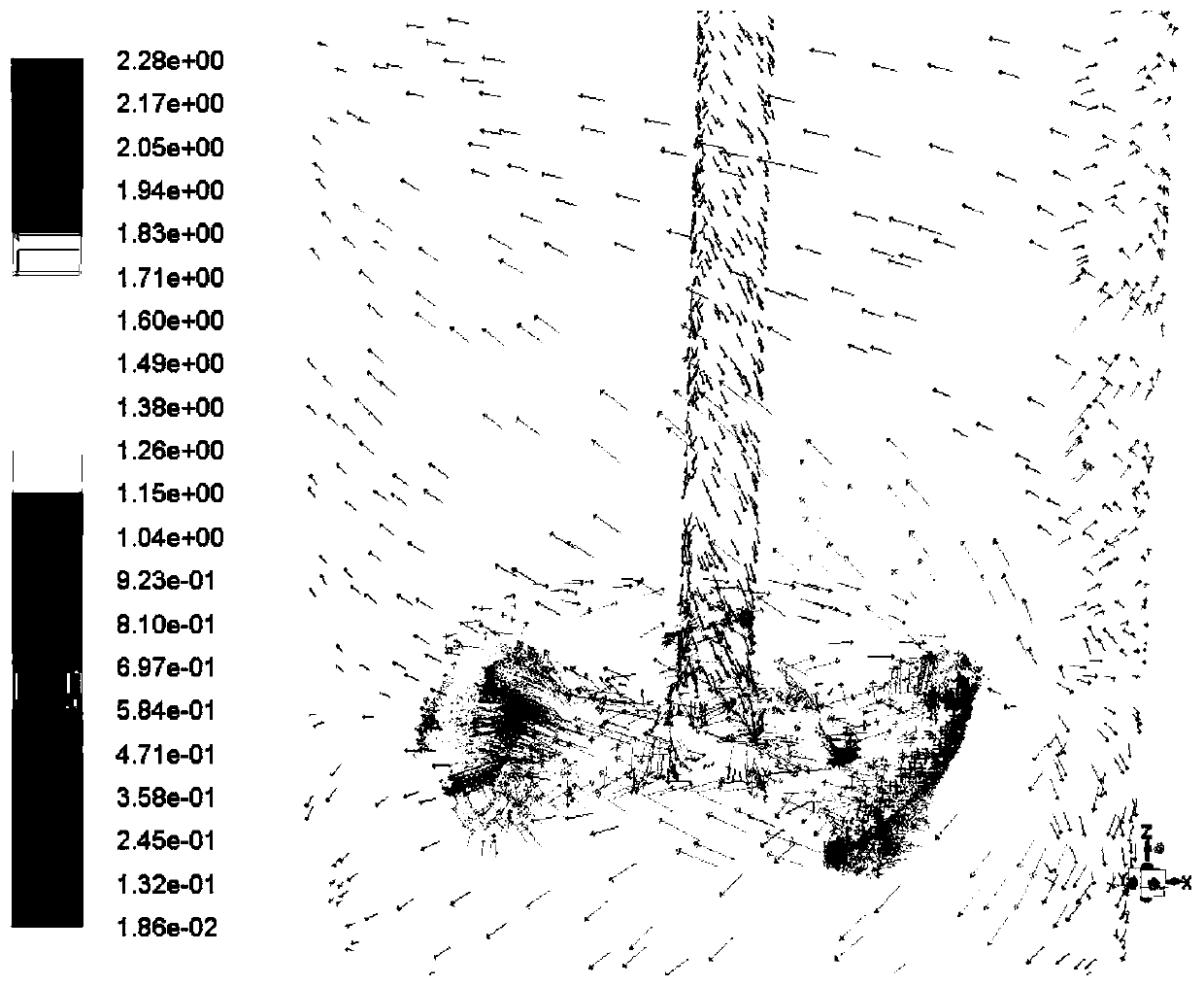

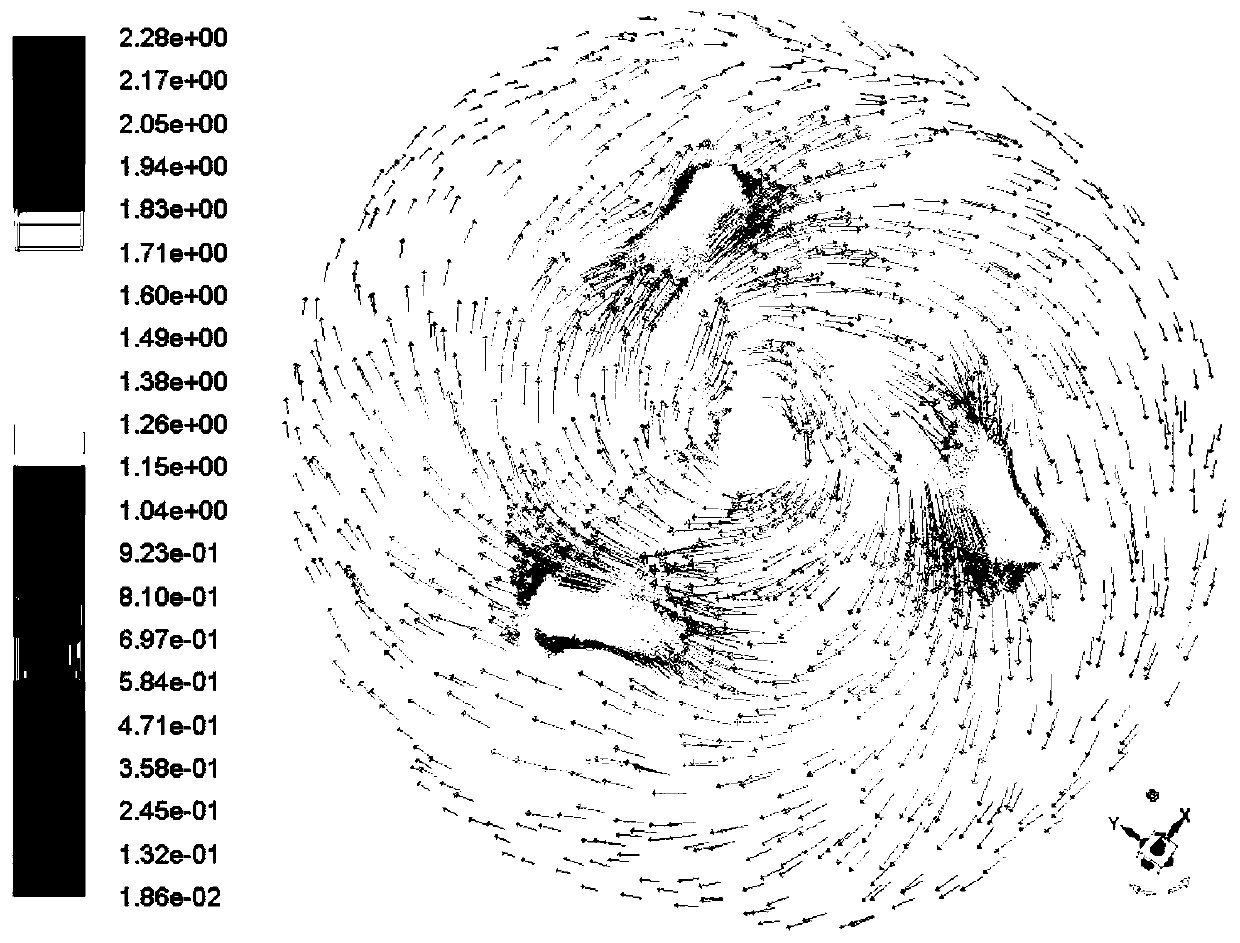

[0046] Such as figure 1 As shown, the dynamic and static combined stirring system of the present invention includes a stirrer 1, and also includes a plurality of static stirring paddles 12 arranged in parallel with the stirring shaft 2 of the stirrer 1, and a plurality of the static stirring paddles 12 surround the stirring shaft 2 Set, the bottom of described stirring shaft 2 is equipped with stirring paddle 4.

[0047] In this embodiment, the distances between the plurality of static stirring paddles 12 and the stirring shaft 2 are not equal. The number of the static stirring paddles 12 can be 2, 3, 4, 5 or 6, etc.

[0048] In this embodiment, the static stirring paddle 12 is a slatted paddle, a cylindrical paddle or a prismatic paddle.

[0049] In this embodiment, taking the stirring shaft 2 of the stirrer 1 as the center, the ratio of the installation radius of the static stirring paddle 12 to the radius of the container used for stirring is 1:7.5˜1:16.

[0050] The spe...

Embodiment 2

[0053] Such as Figure 7 As shown, the autoclave used in the present invention is equipped with a dynamic and static combined stirring system, including an autoclave 8 with an open top, and a sealing cover 3 arranged at the opening of the autoclave 8, on which a stirring 1, the stirring shaft 2 of the stirrer 1 is located in the autoclave 8, the bottom of the stirring shaft 2 is equipped with a stirring paddle 4, and a plurality of static stirring paddles 12 are fixedly installed on the sealing cover 3. The stirring paddles 12 are arranged around the stirring shaft 2 , and the ends of the plurality of static stirring paddles 12 away from the sealing cover 3 go deep into the autoclave 8 .

[0054] In this embodiment, the distances between the plurality of static stirring paddles 12 and the stirring shaft 2 are not equal. The number of the static stirring paddles 12 can be 2, 3, 4, 5 or 6, etc.

[0055] In this embodiment, the static stirring paddle 12 is a slatted paddle, a c...

Embodiment 3

[0065] The process of preparing chromium salts by liquid-phase oxidation of chromite ore using a high-pressure reactor equipped with a dynamic and static combined stirring system described in Example 2 includes:

[0066] Add 125g of chromite (300 mesh), 250g of sodium hydroxide and 583g of water into a high-pressure reactor equipped with a dynamic and static combined stirring system; under stirring conditions, feed oxygen into the high-pressure reactor for liquid phase oxidation reaction, and the liquid phase The reaction temperature of the oxidation reaction is 180°C, the oxygen partial pressure is 1.2MPa (total pressure is about 2.4MPa), the stirring speed is 500rpm, and the reaction time is 1h; Heat preservation and settlement in the box, the temperature of heat preservation and settlement is 70 ° C, and the time is 120 minutes; the solid-liquid separation is carried out on the material after heat preservation and settlement, and the supernatant and reaction slag are obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com